Centric Software announces the acquisition of Contentserv, an AI-powered, Cloud-based PIM, DAM, Content Syndication and Digital Shelf Analytics Solution.

Click here to read the PR

#1 PRODUCT LIFECYCLE MANAGEMENT SOFTWARE

Discover the Market-Leading PLM Solution for Consumer Goods

Leave data chaos and manual systems behind with Centric Product Lifecycle Management (Centric PLM™). Develop profitable products while achieving sustainability and traceability goals with a flexible, easy to use and scalable digital foundation for growth.

Request a demo

+28%

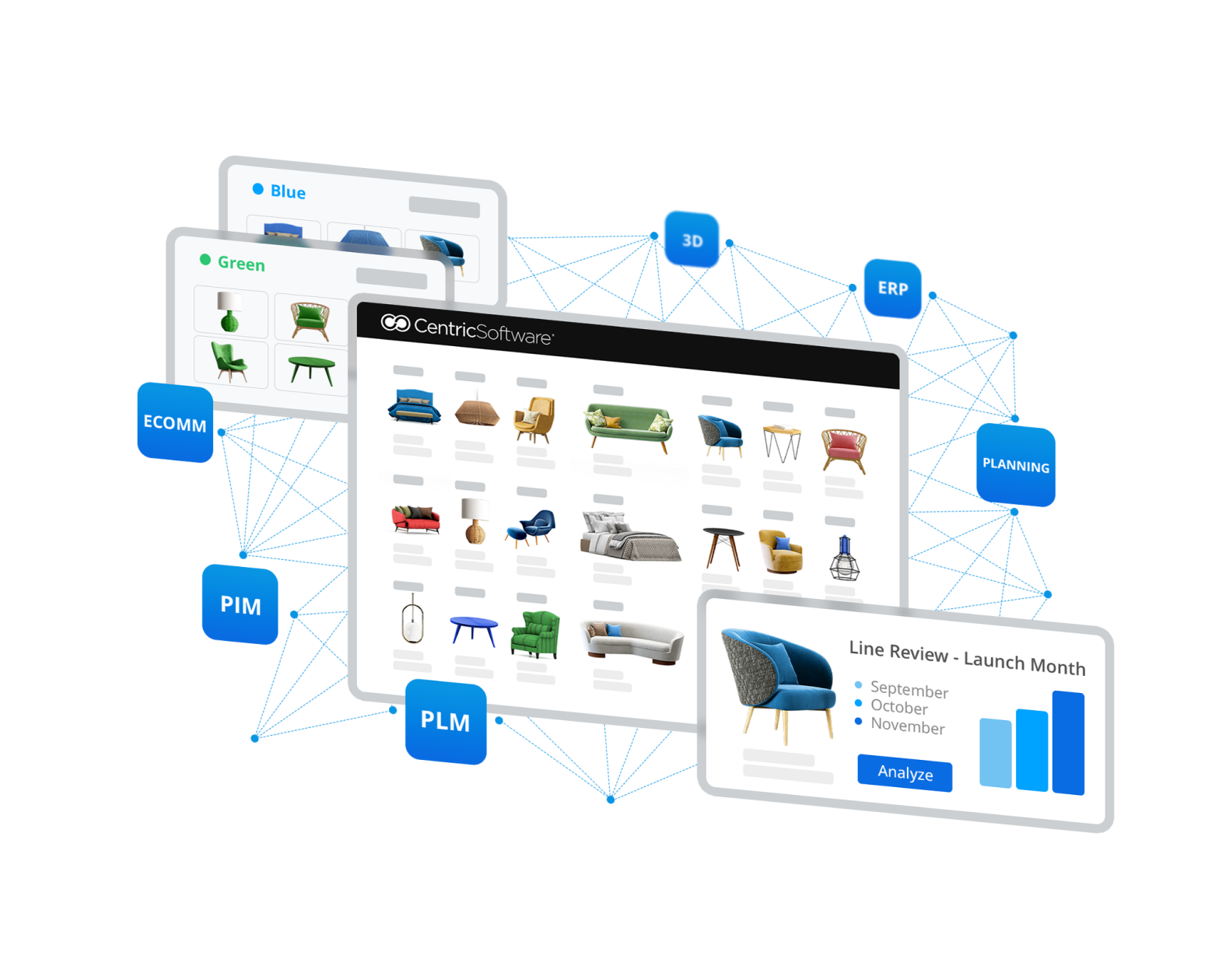

Centric PLM is your single source of truth.

Centric PLM connects the people, systems and processes in your value chain to optimize product go-to-market and performance at retail.

one source of truth

Save time wasted searching for key data in Excel, PDFs and emails. Connect teams with live data.

Improve collaboration

Enable teams and external stakeholders to collaborate effectively in real time.

Speed time to market

Develop products rapidly and ensure accurate, on-time delivery to satisfy consumers.

Harmonize product data

Track and leverage all historical and current product data to boost efficiency.

Stay close to consumers

Anticipate trends and react quickly to gain a competitive advantage.

Manage growth

Optimize categories, SKUs, channels and markets while developing sustainably.

one source of truth

Save time wasted searching for key data in Excel, PDFs and emails. Connect teams with live data.

Improve collaboration

Enable teams and external stakeholders to collaborate effectively in real time.

Speed time to market

Develop products rapidly and ensure accurate, on-time delivery to satisfy consumers.

Harmonize product data

Track and leverage all historical and current product data to boost efficiency.

Stay close to consumers

Anticipate trends and react quickly to gain a competitive advantage.

Manage growth

Optimize categories, SKUs, channels and markets while developing sustainably.

How do you use Centric PLM?

How do you use Centric PLM?

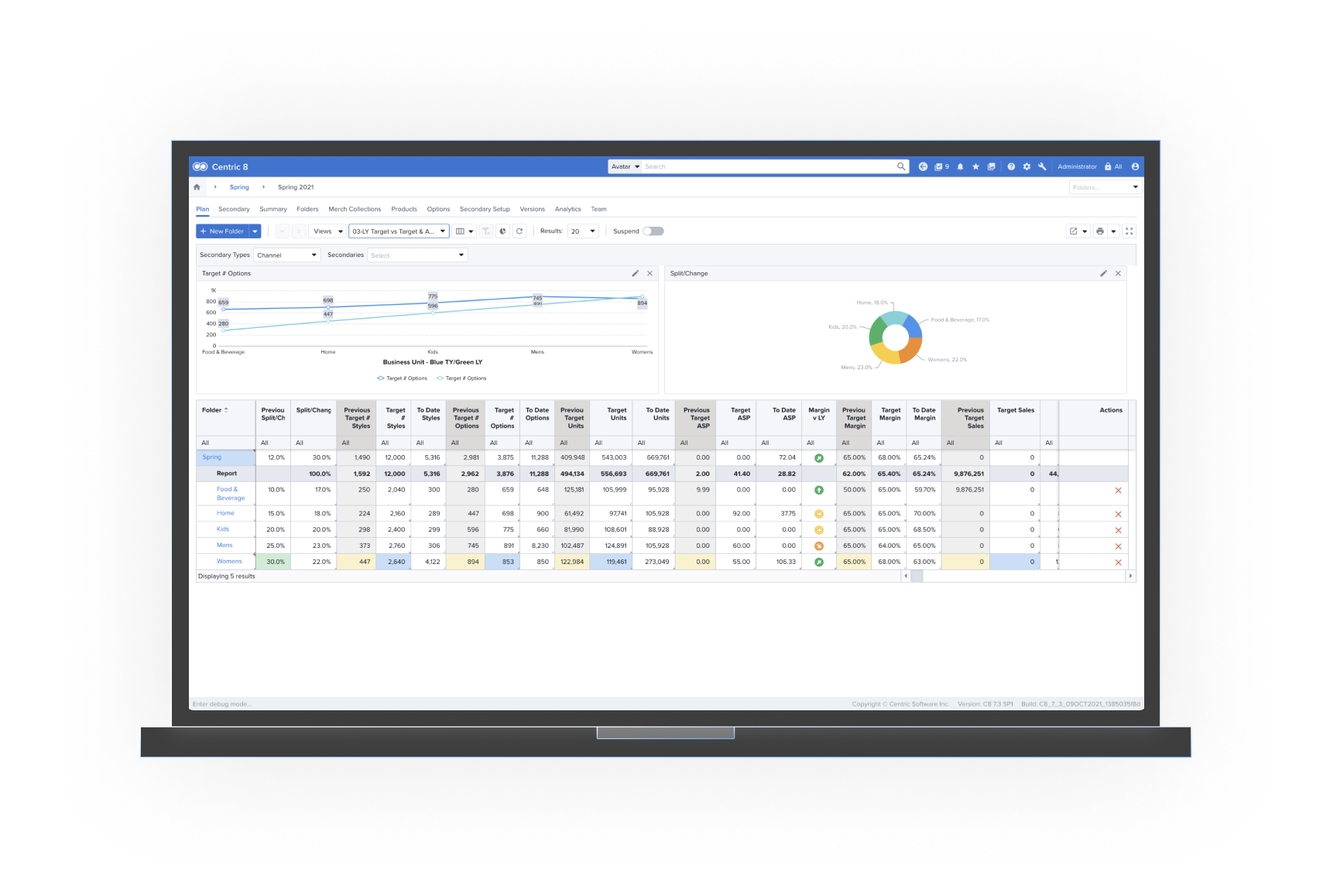

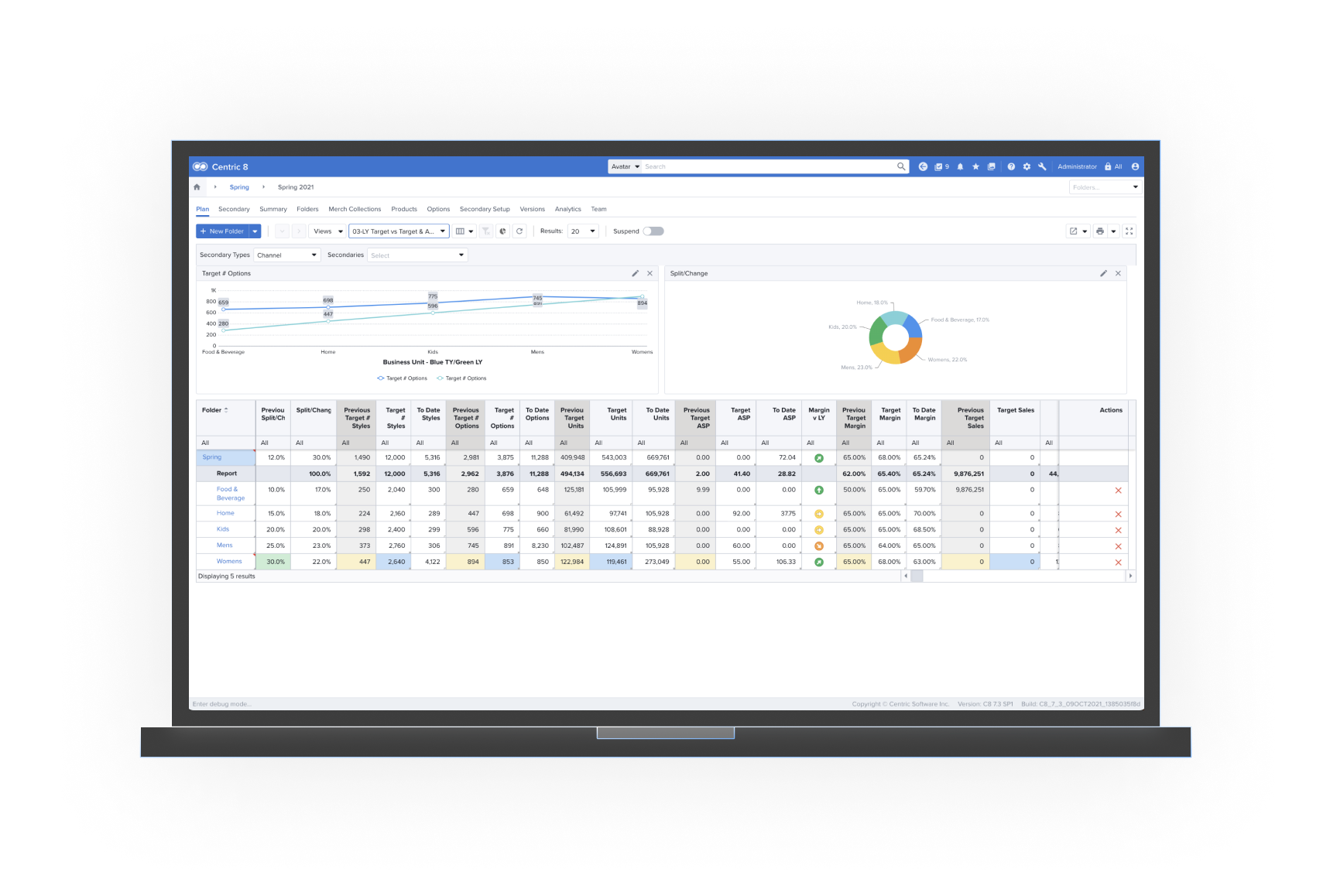

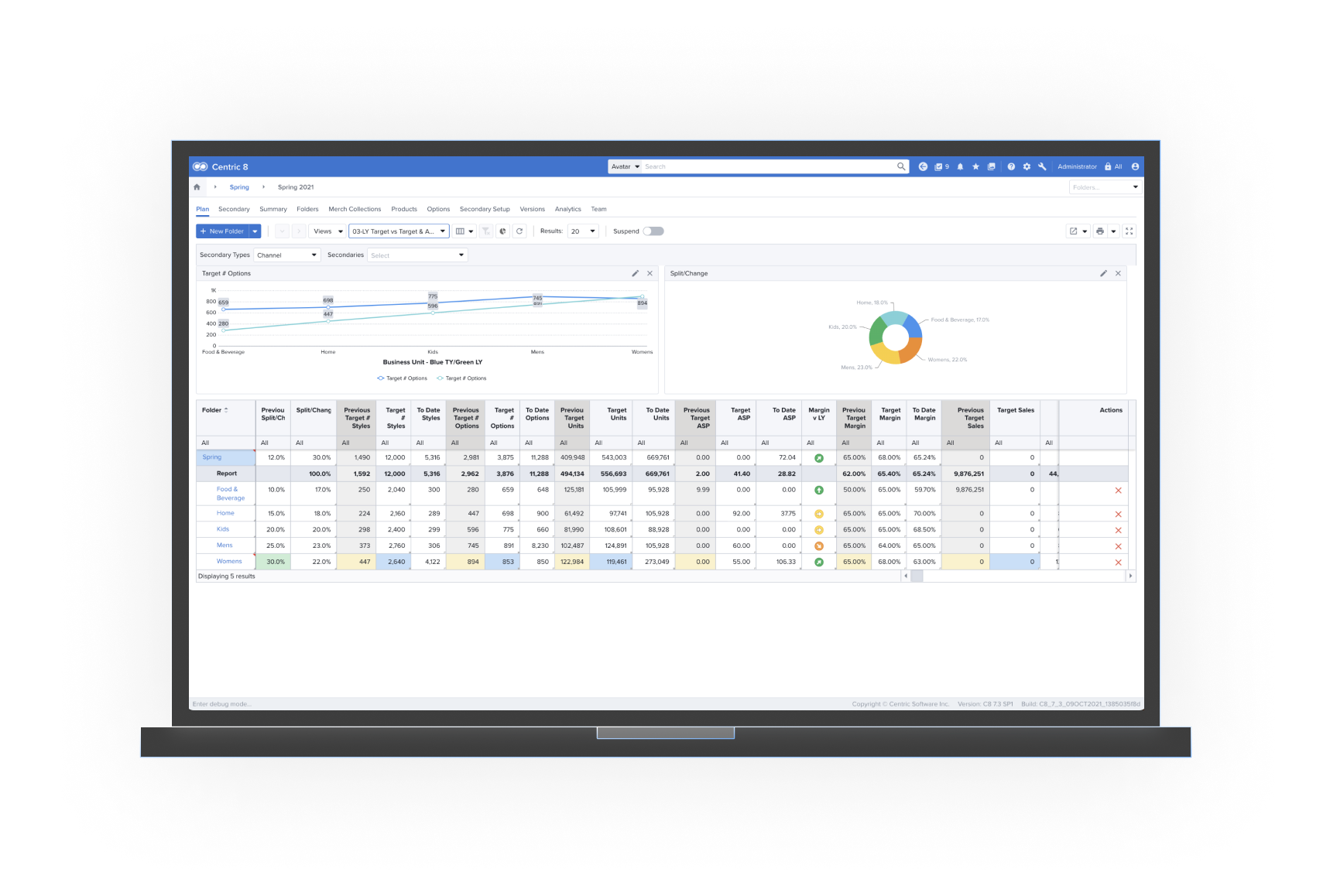

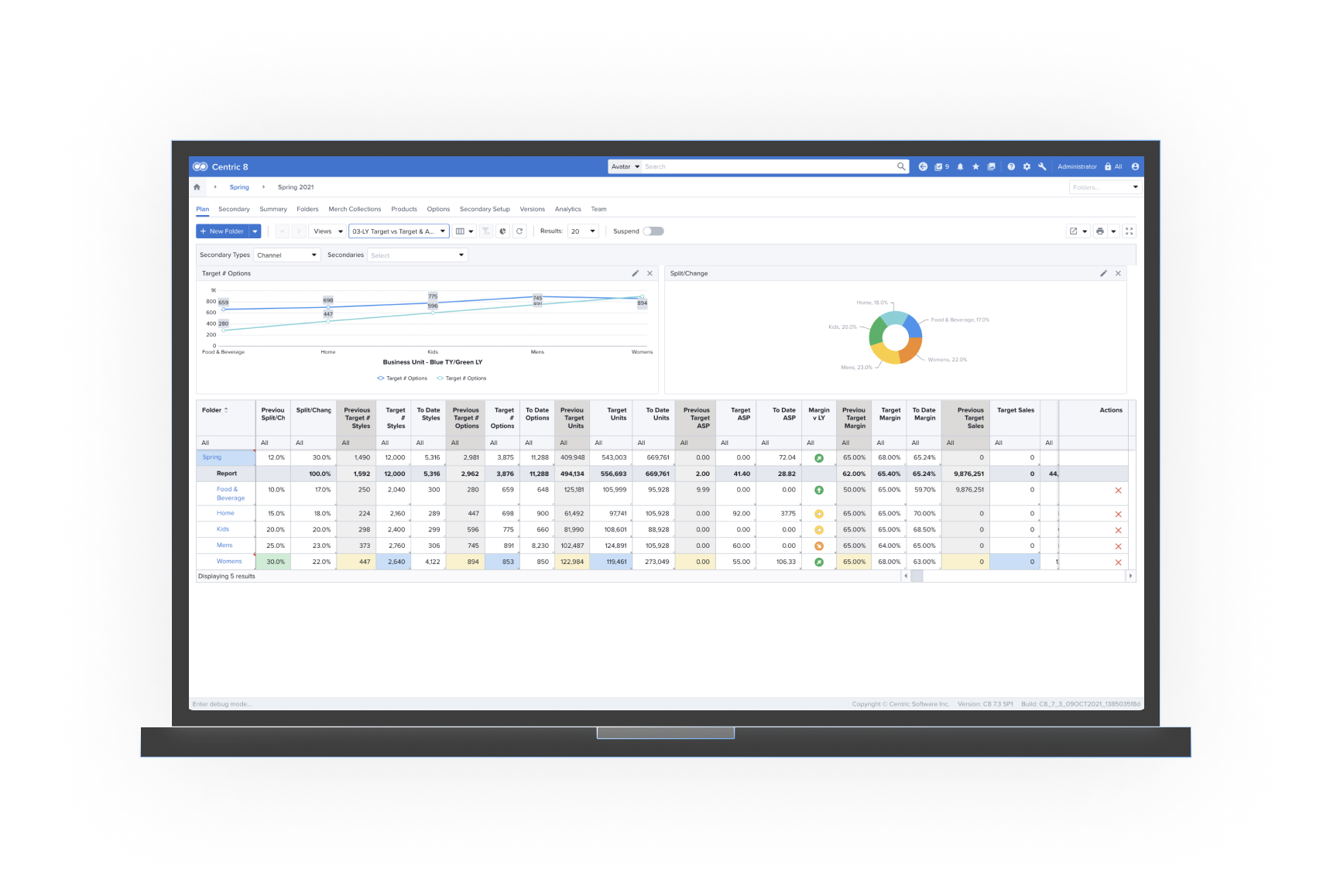

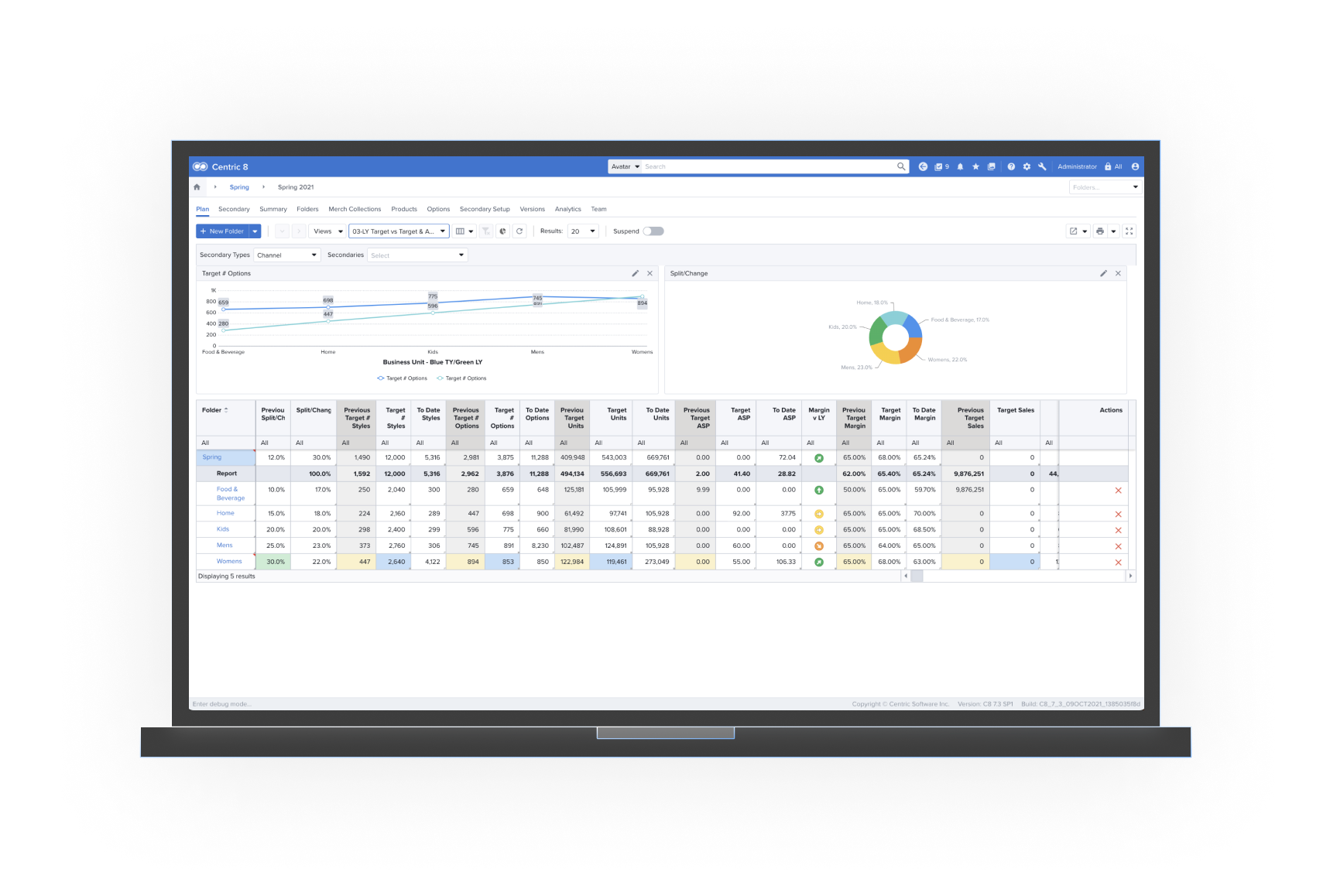

Planning

Easily see priorities and manage accordingly

View holistically and collaborate on season planning

Know exactly where a product is in its lifecycle

Leverage data from past seasons to forecast demand and plan successful products

Build accurate reports quickly, based on up-to-date information

How do you use Centric PLM?

Merchandising

Manage seasons, departments, collections and specific styles to meet performance targets, using up-to-date information

Gain full visibility into material costs and product margins

Run dynamic what-if scenarios using live data from PLM and other enterprise solutions to make better decisions

Quickly create visual line plans and share information

How do you use Centric PLM?

Design

Eliminate or reduce manual tasks, freeing up time to focus on creativity

Stay in sync with merchandising and planning

Access material libraries and historical product data

Connect 3D design platforms with PLM to streamline product and packaging design

Co-create with suppliers and agencies using a single source of truth

How do you use Centric PLM?

How do you use Centric PLM?

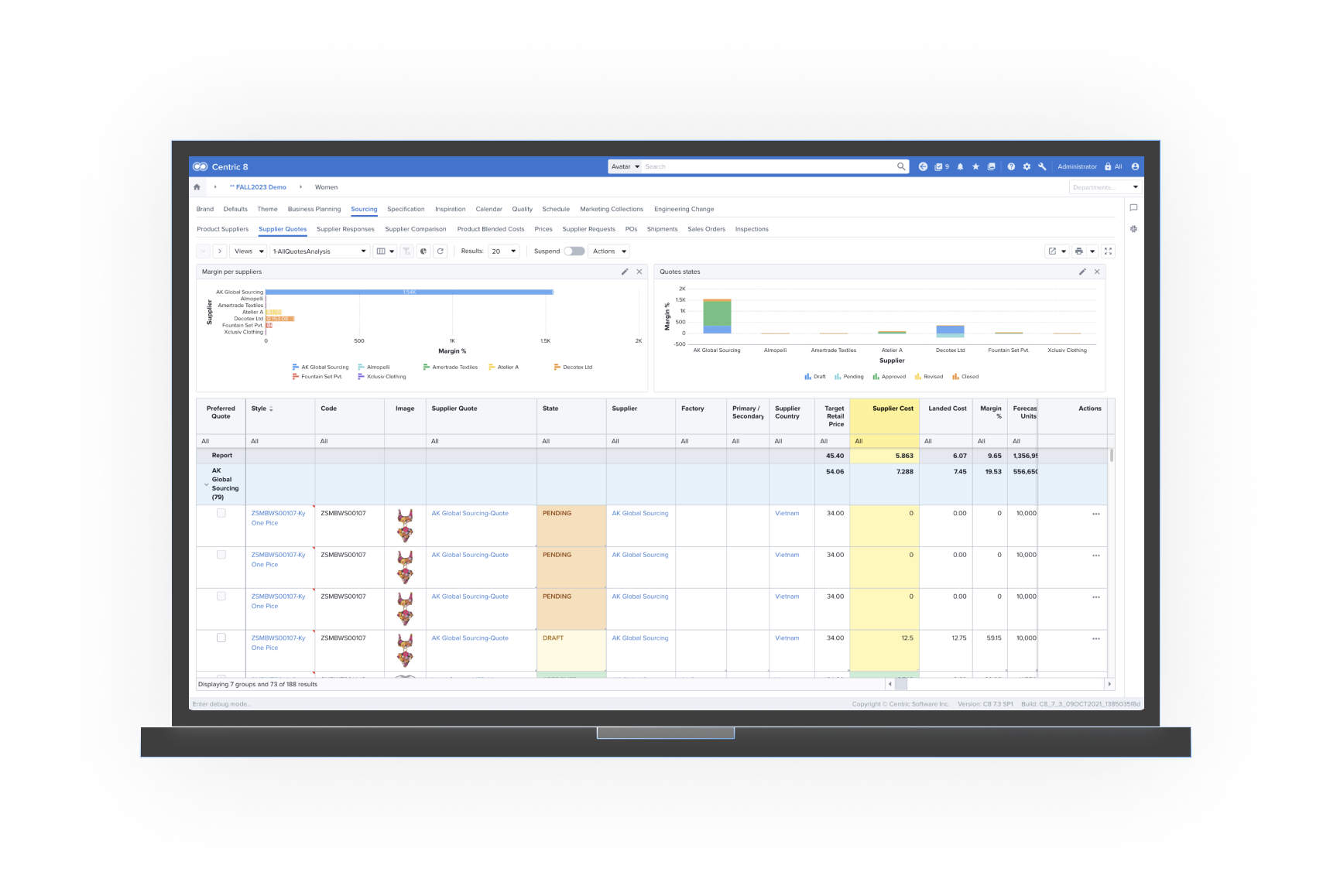

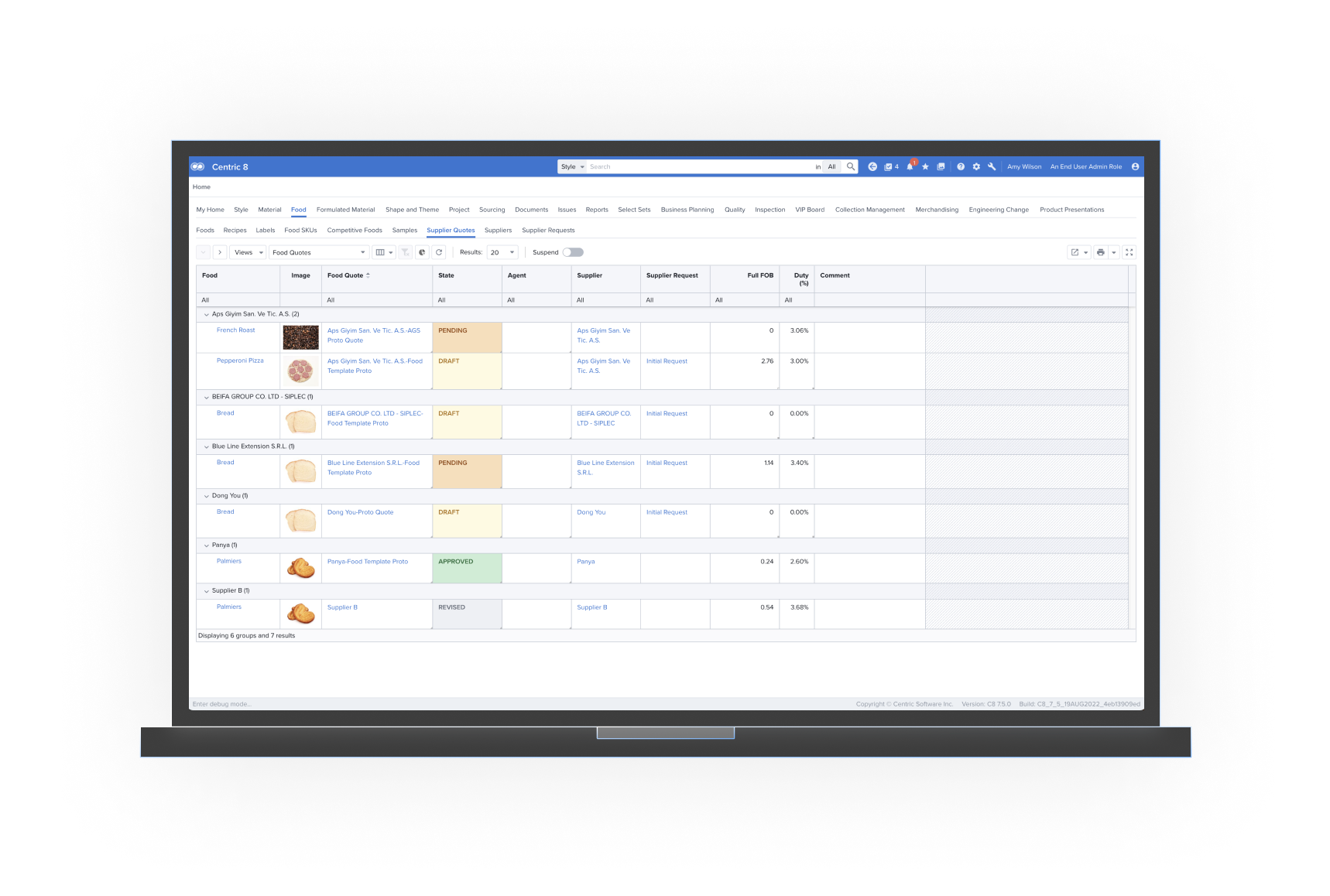

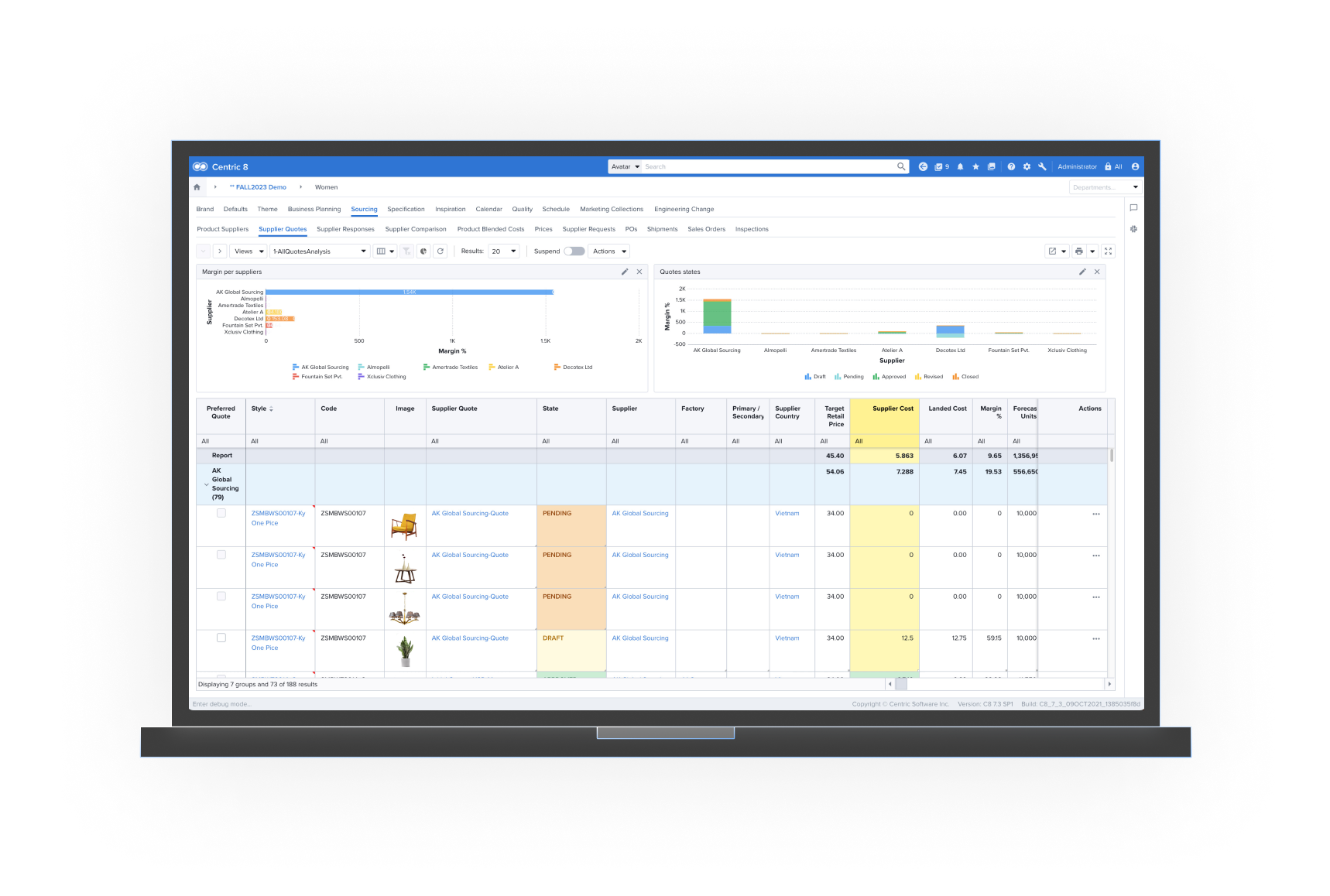

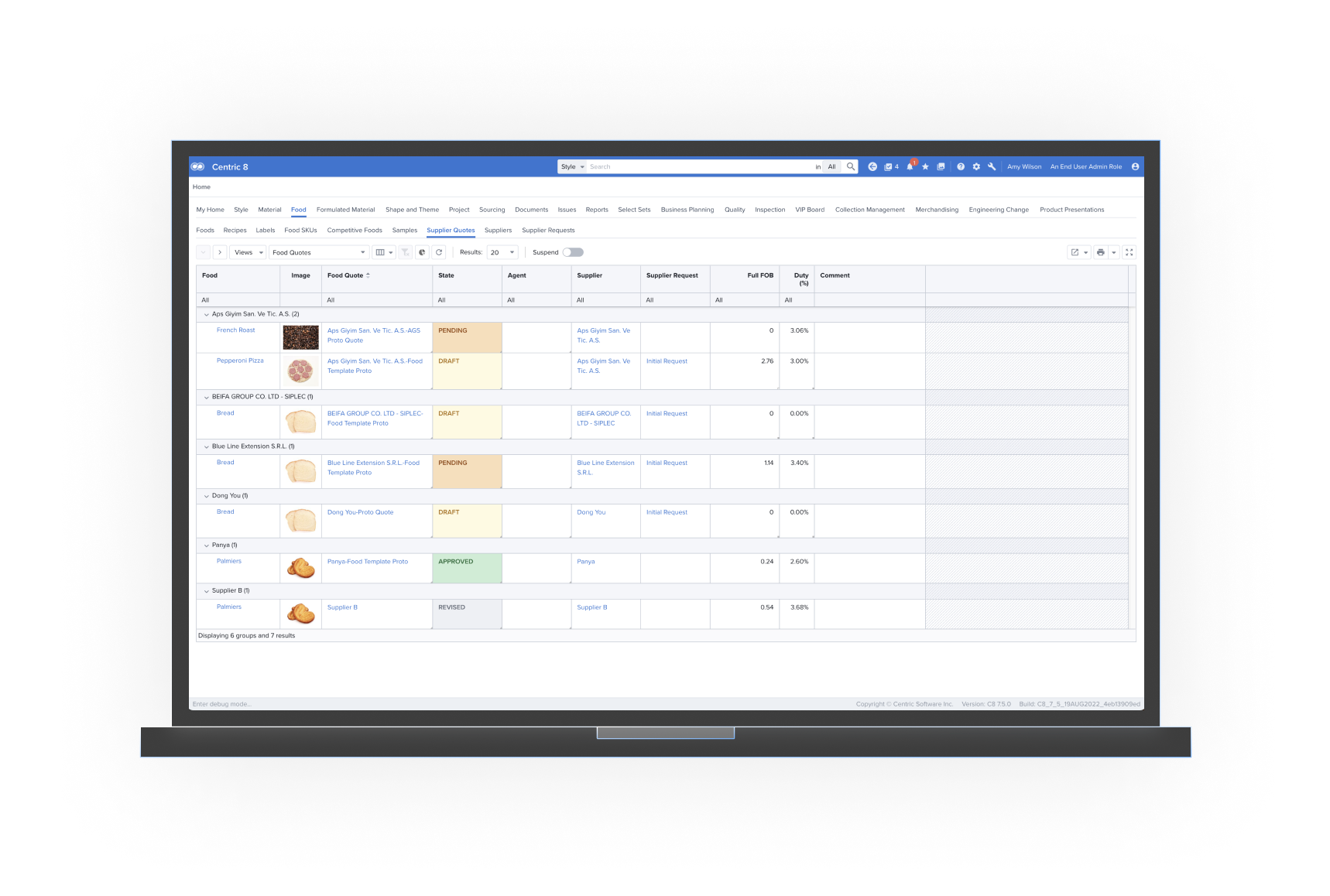

Sourcing

Gain full visibility into material costs/product margins

Control flow of information while giving suppliers access to necessary data

Evaluate and rationalize your supplier base

Issue RFQs en masse and easily compare price quotes

Connect suppliers through the PLM supplier portal to improve collaboration

How do you use Centric PLM?

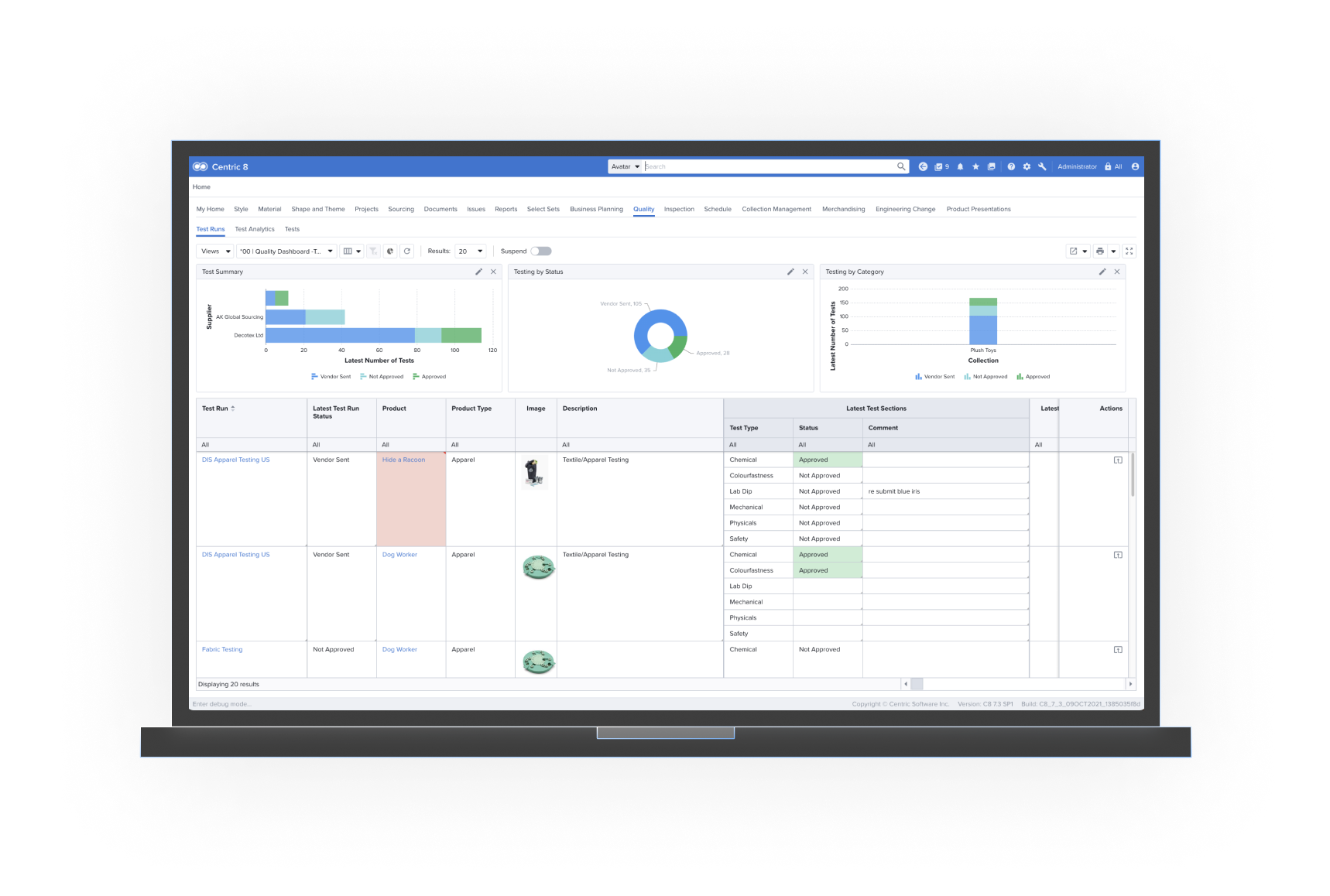

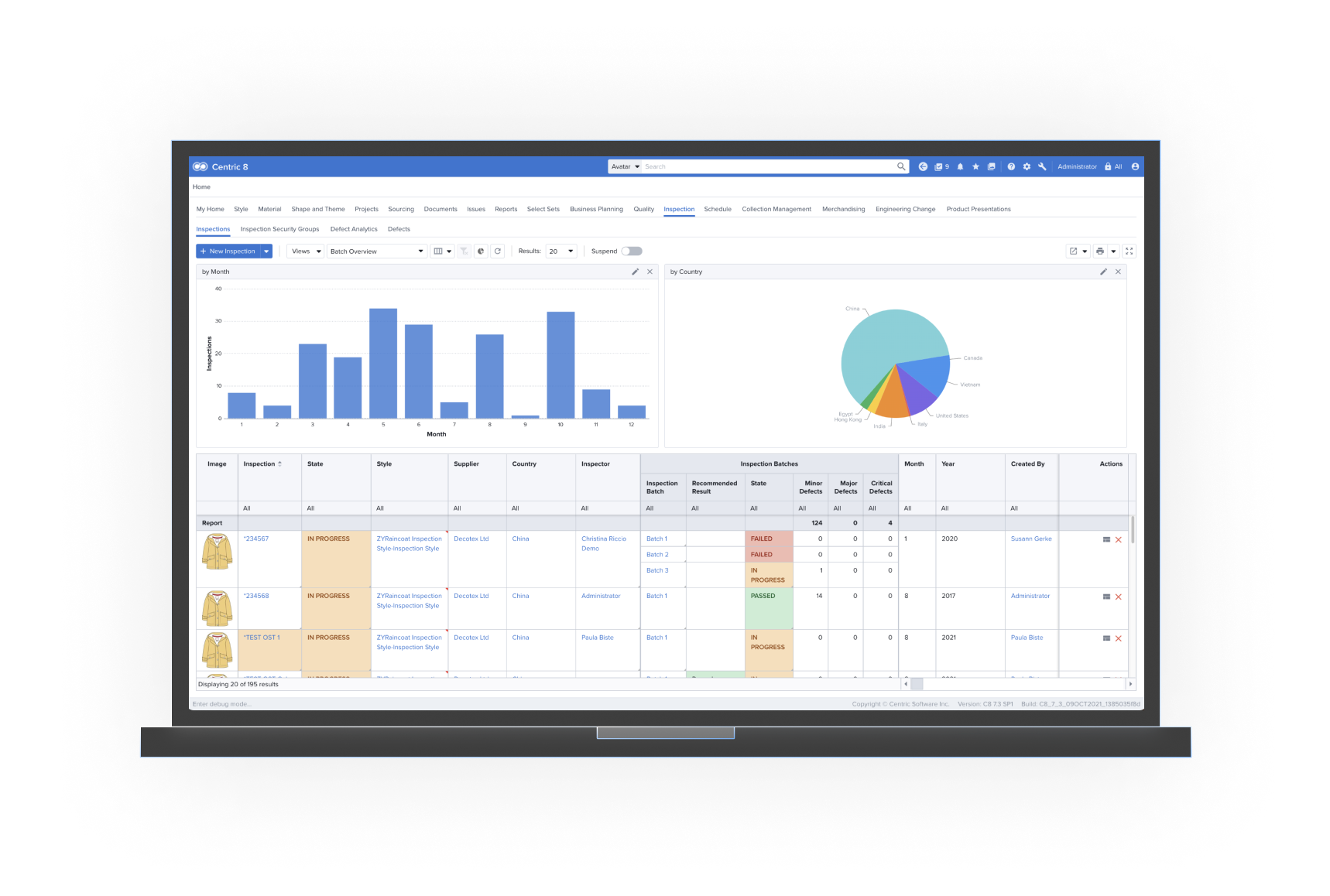

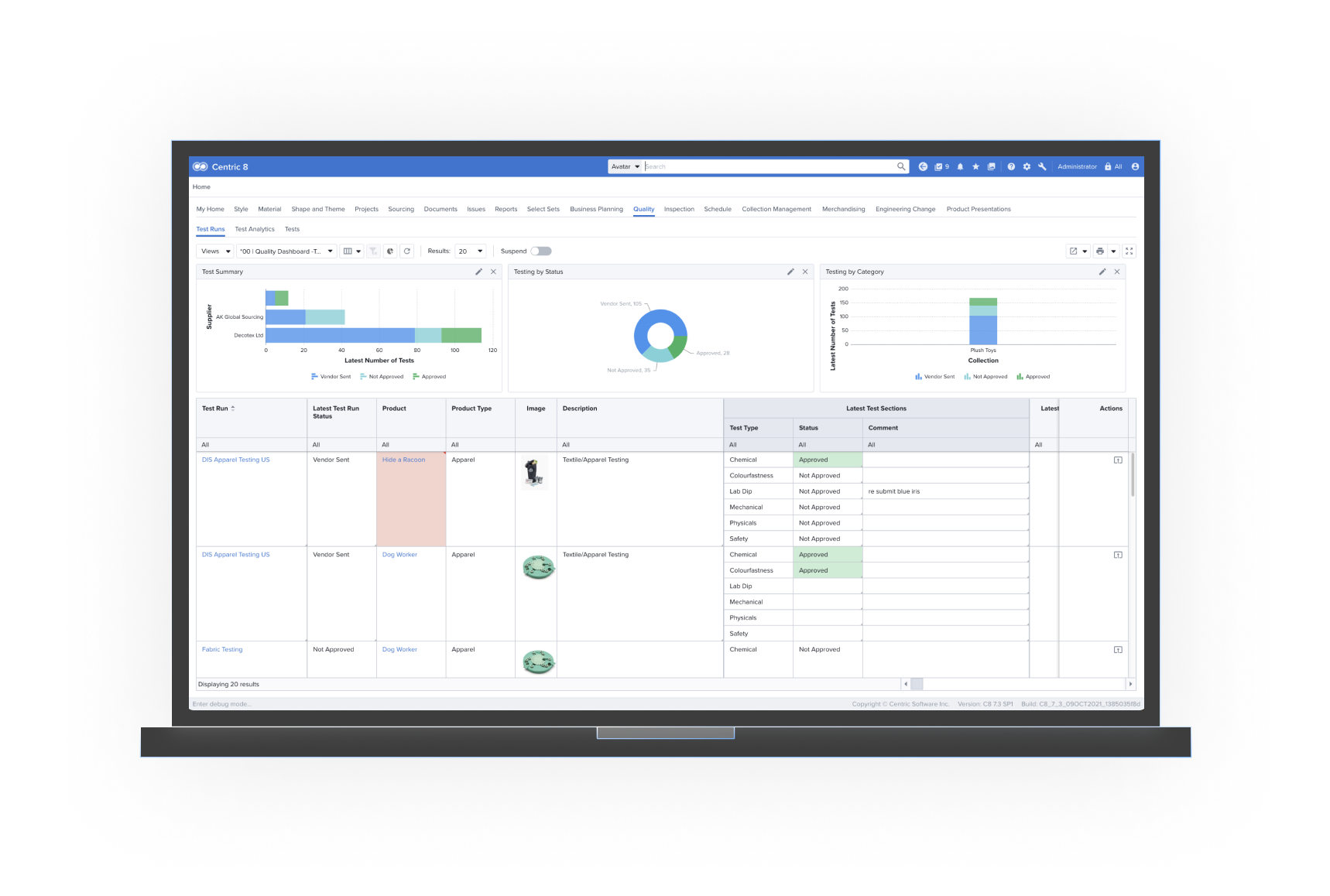

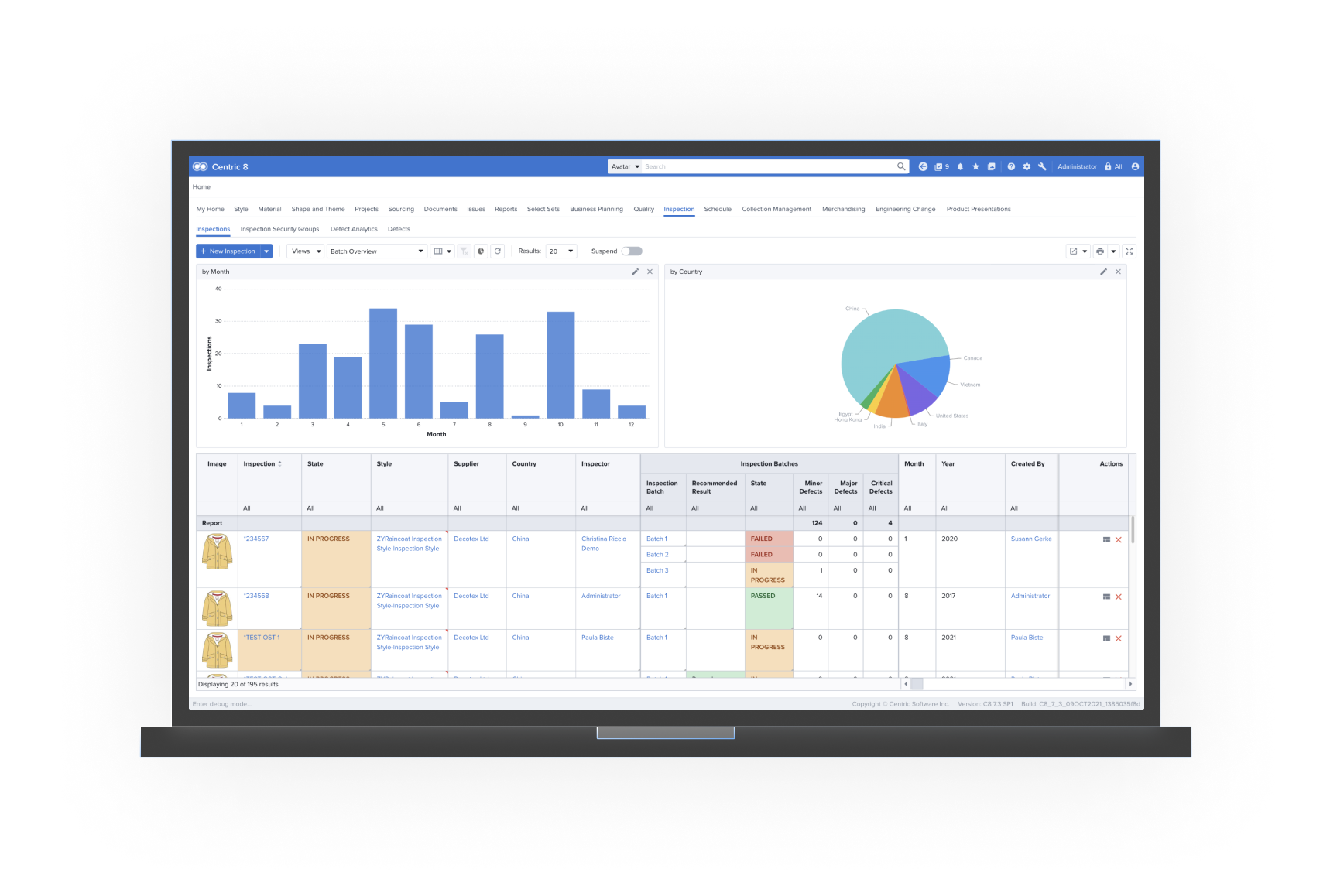

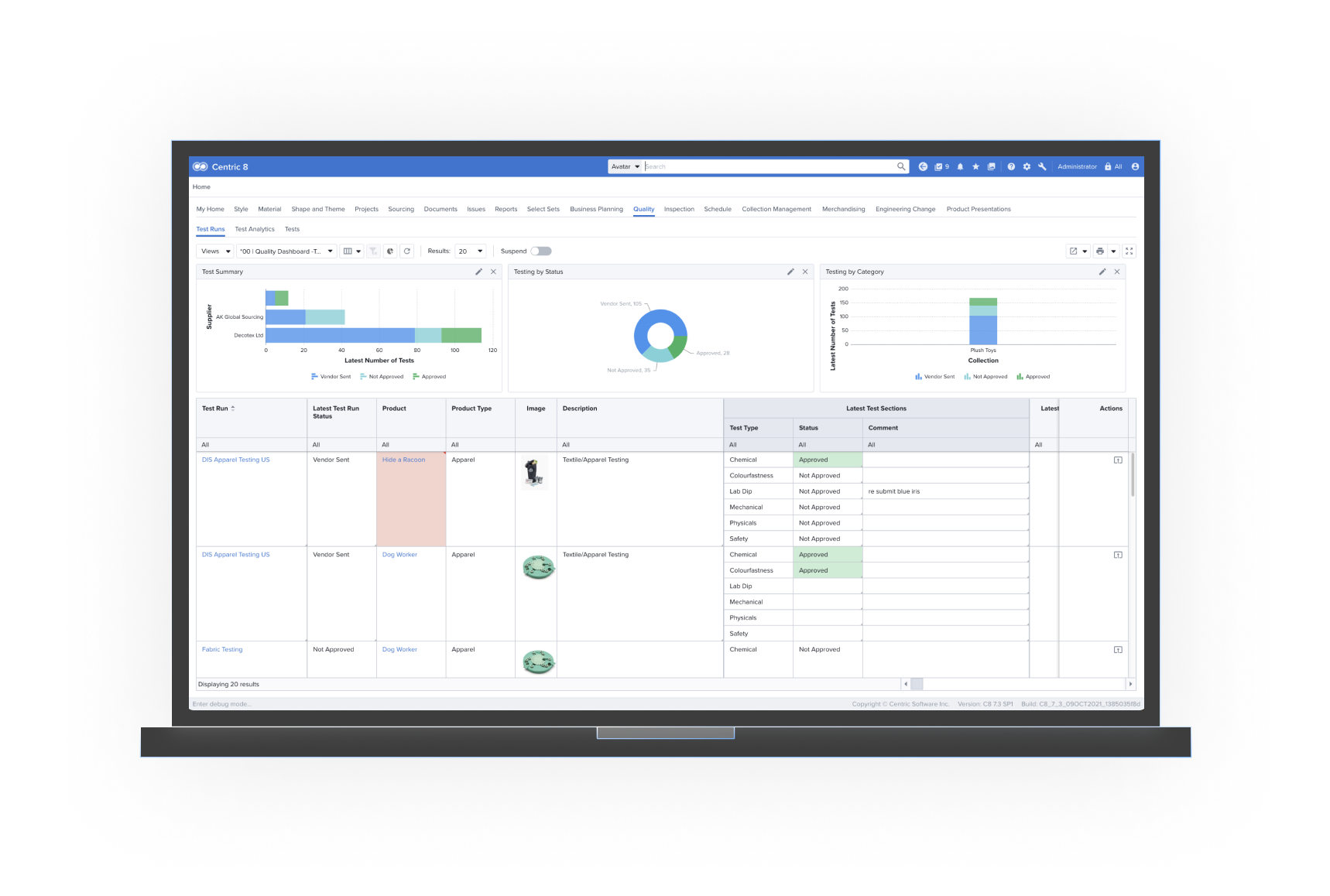

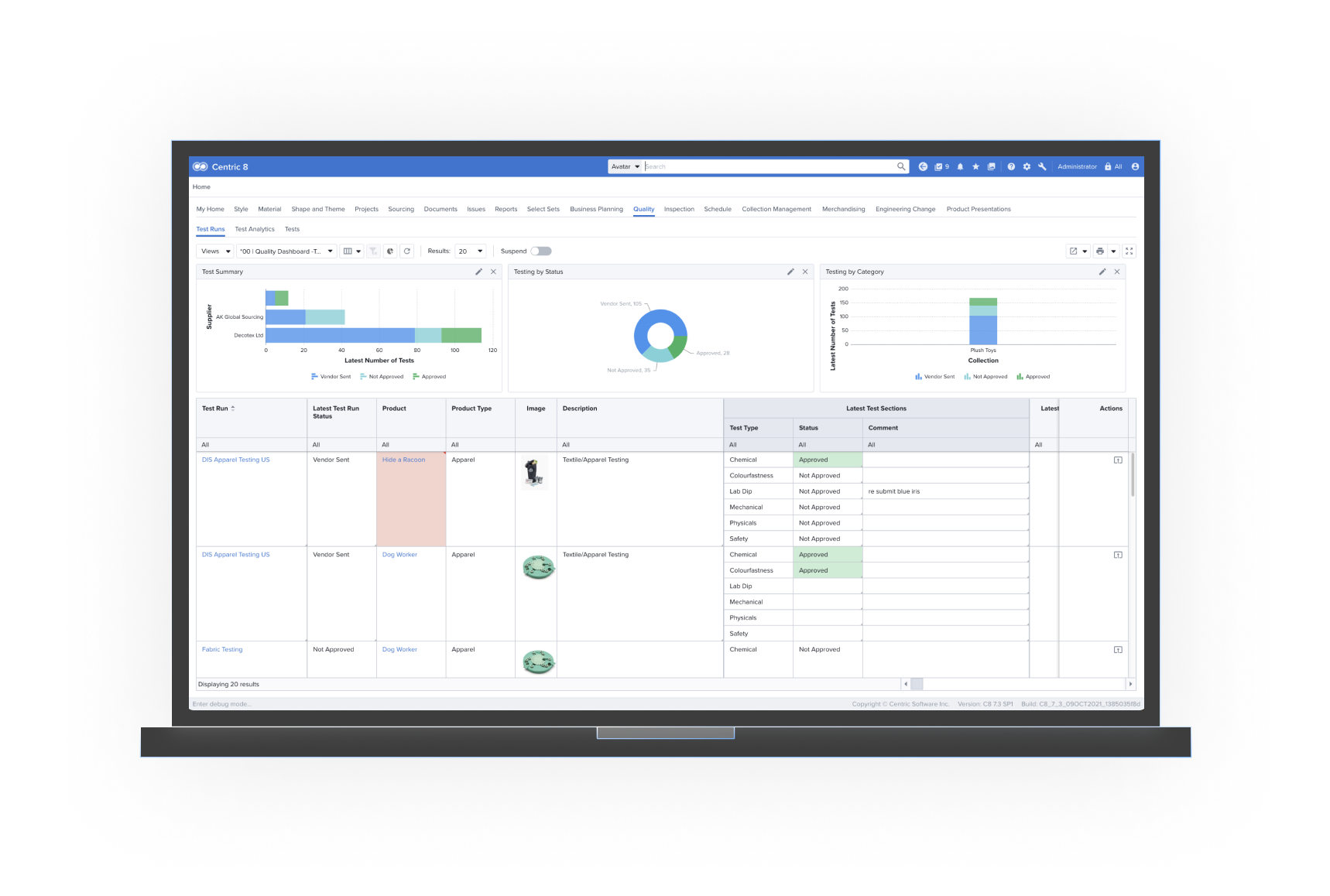

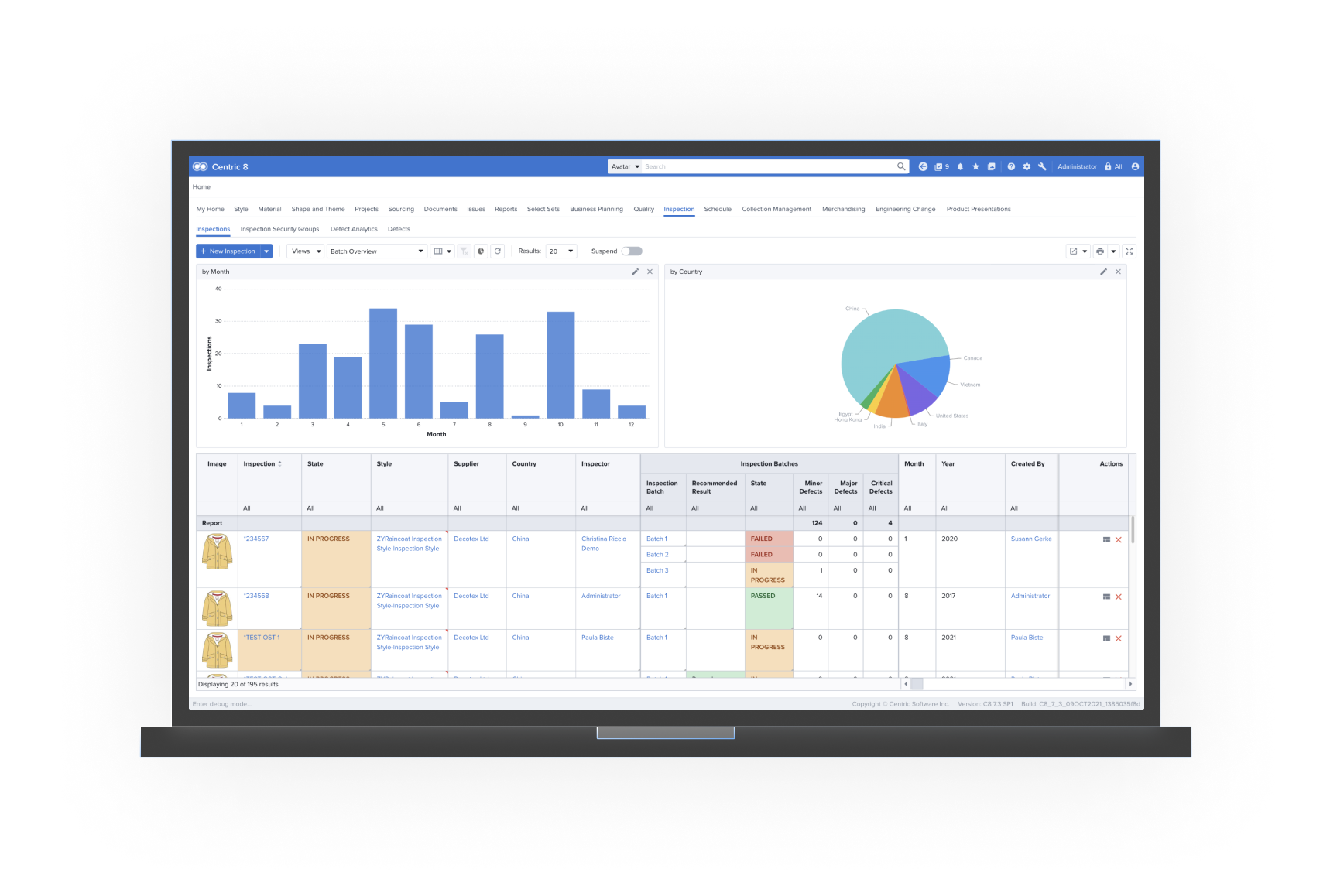

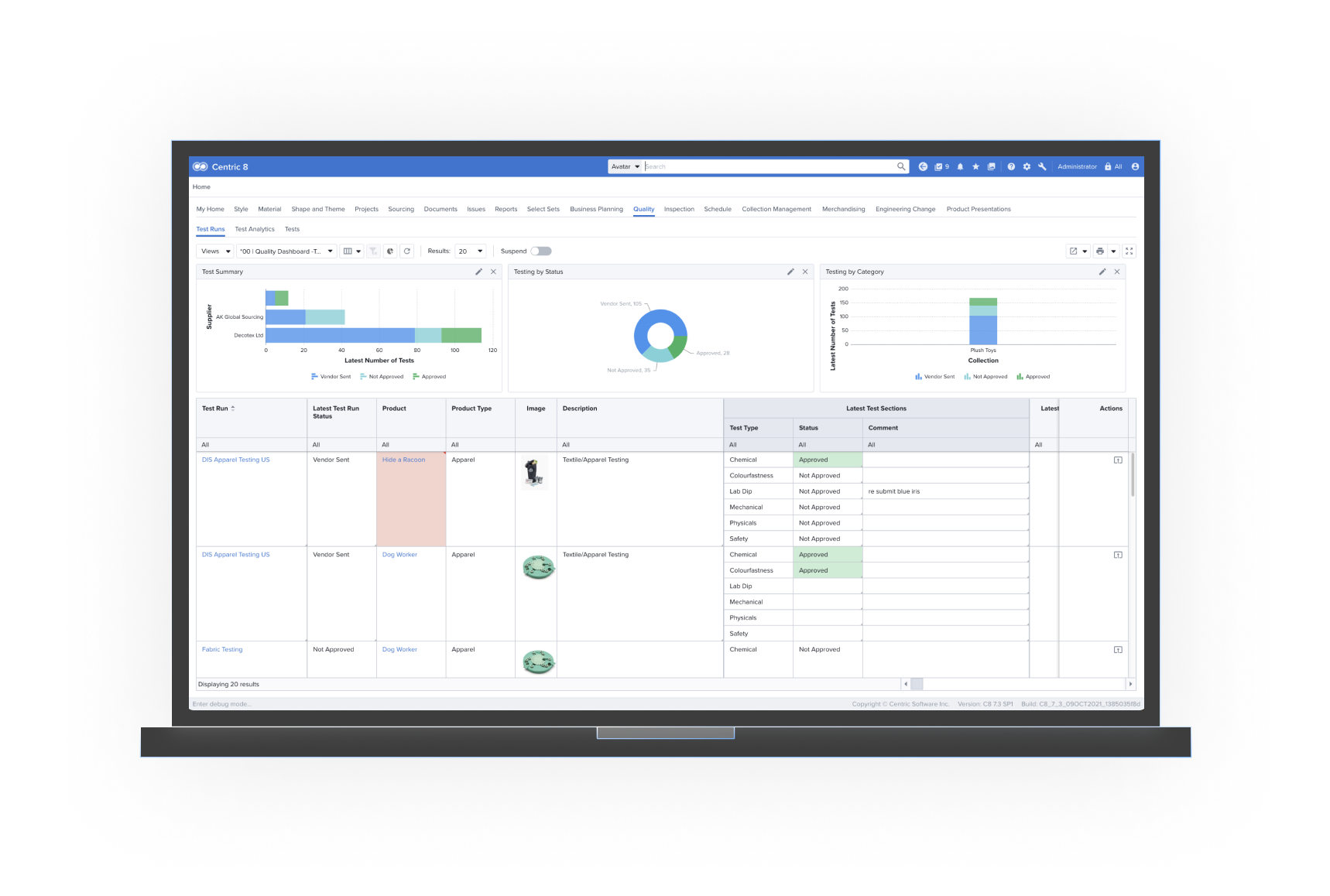

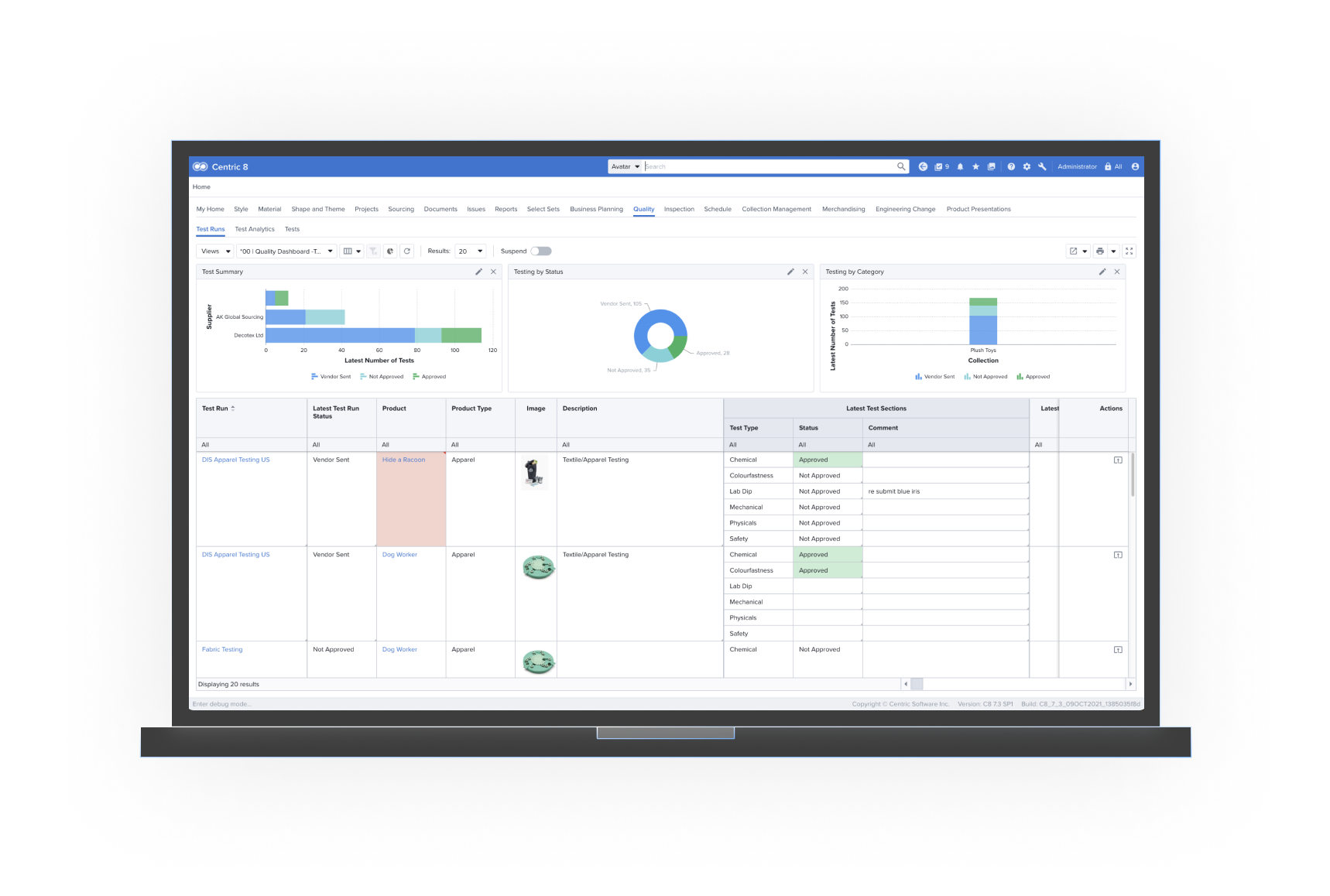

Quality

Manage quality control and inspections with mobile apps and templates directly connected to PLM that are accessible by all team members in real time

Facilitate supplier self-assessments and other third-party assessments using audit templates, mobile applications, and alert settings

Develop high-quality products that meet consumer expectations

How do you use Centric PLM?

Compliance

Maintain compliance documentation in a single, up-to-date digital location

Flag outliers and adapt rapidly to regulatory changes with change management

Track products throughout the complete lifecycle to manage traceability

Maintain data necessary to meet regulatory requirements and satisfy customers, such as sustainability credentials

How do you use Centric PLM?

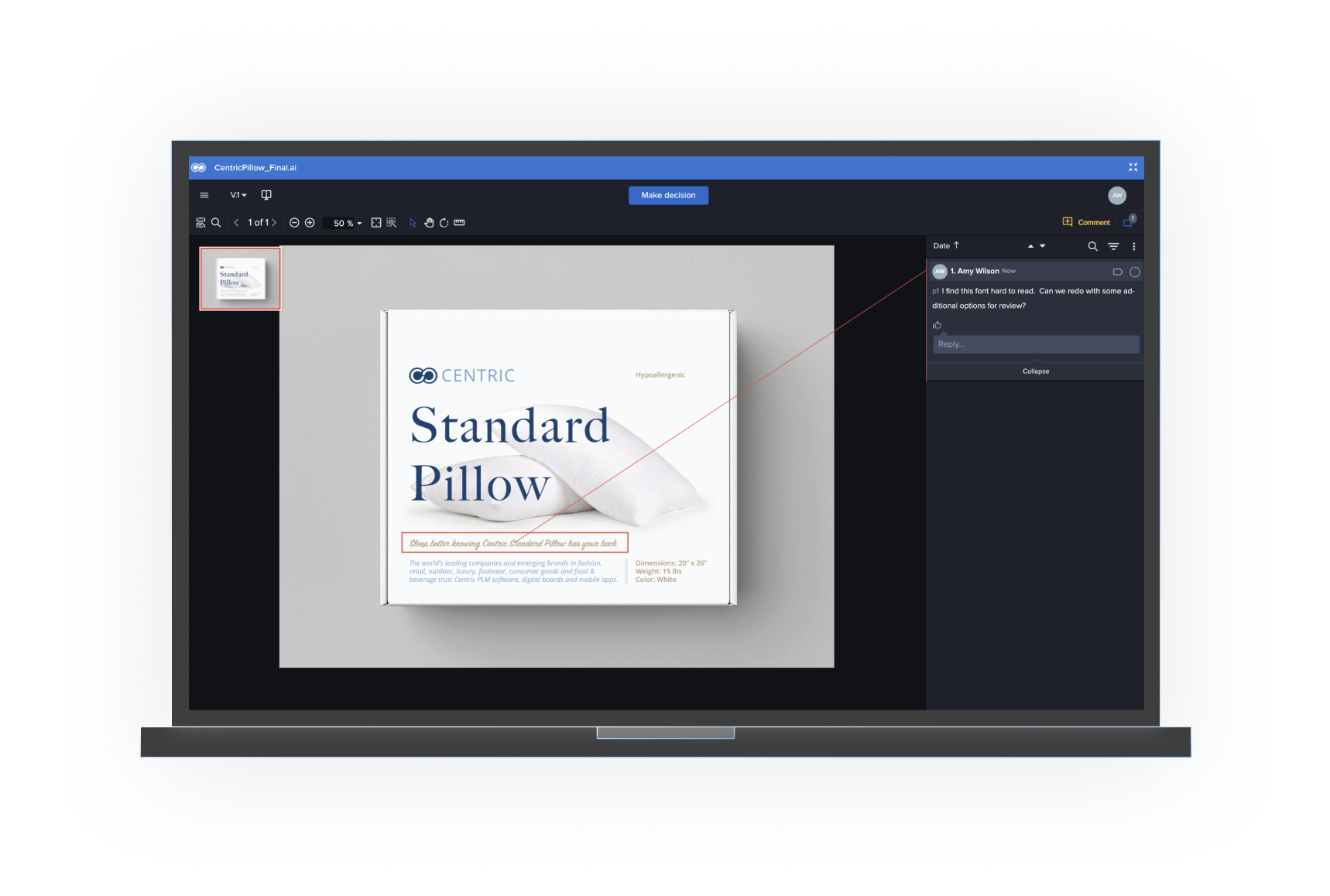

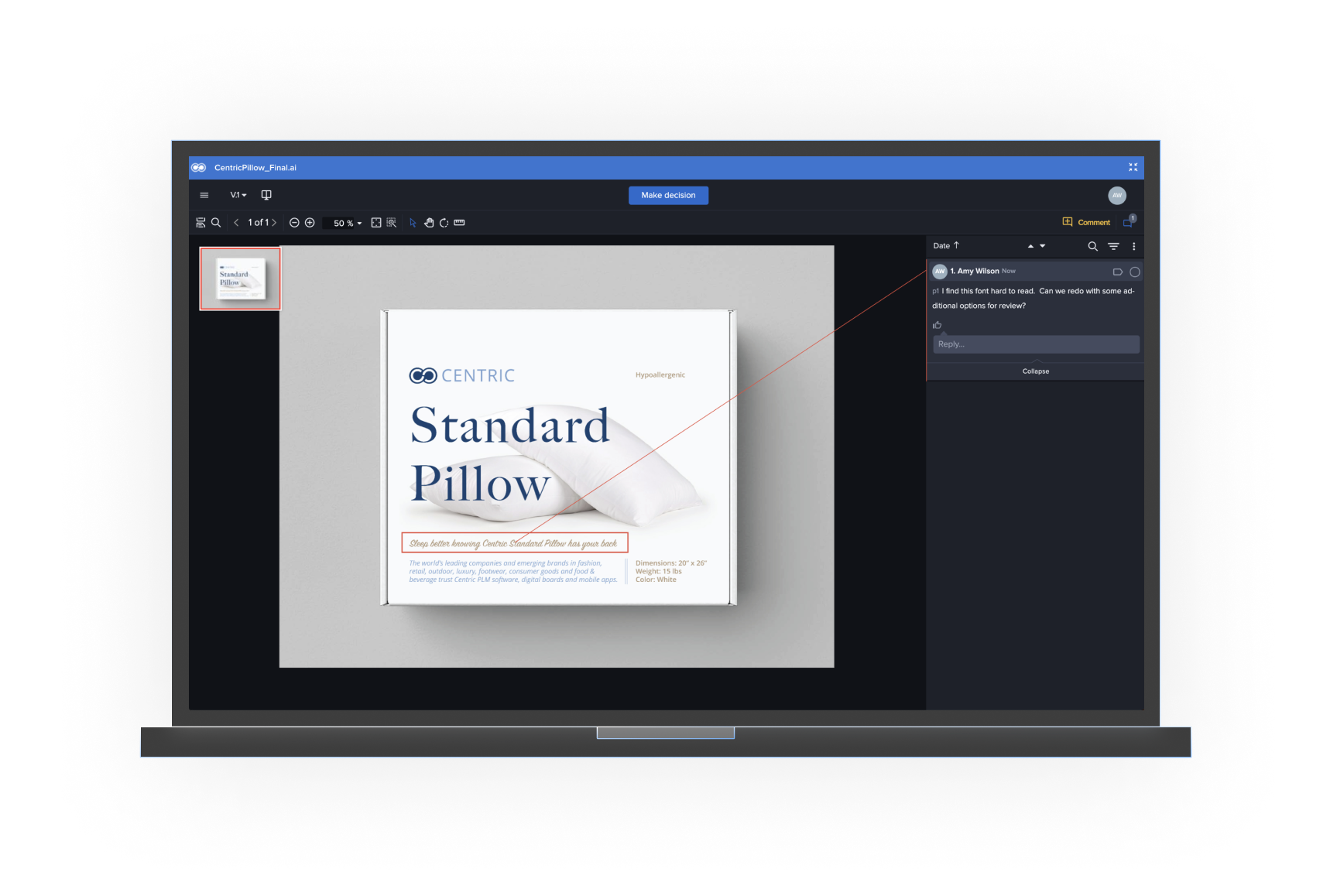

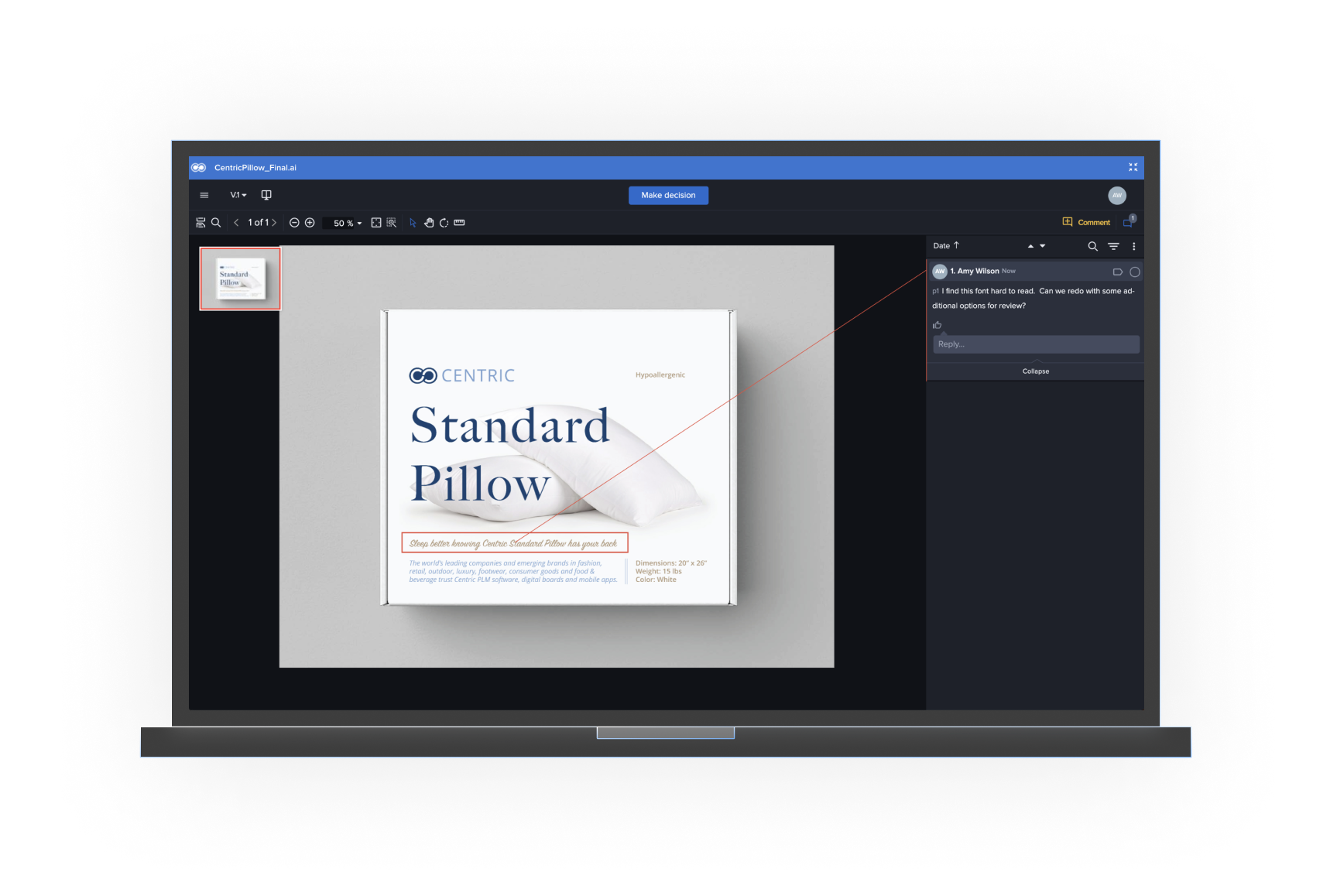

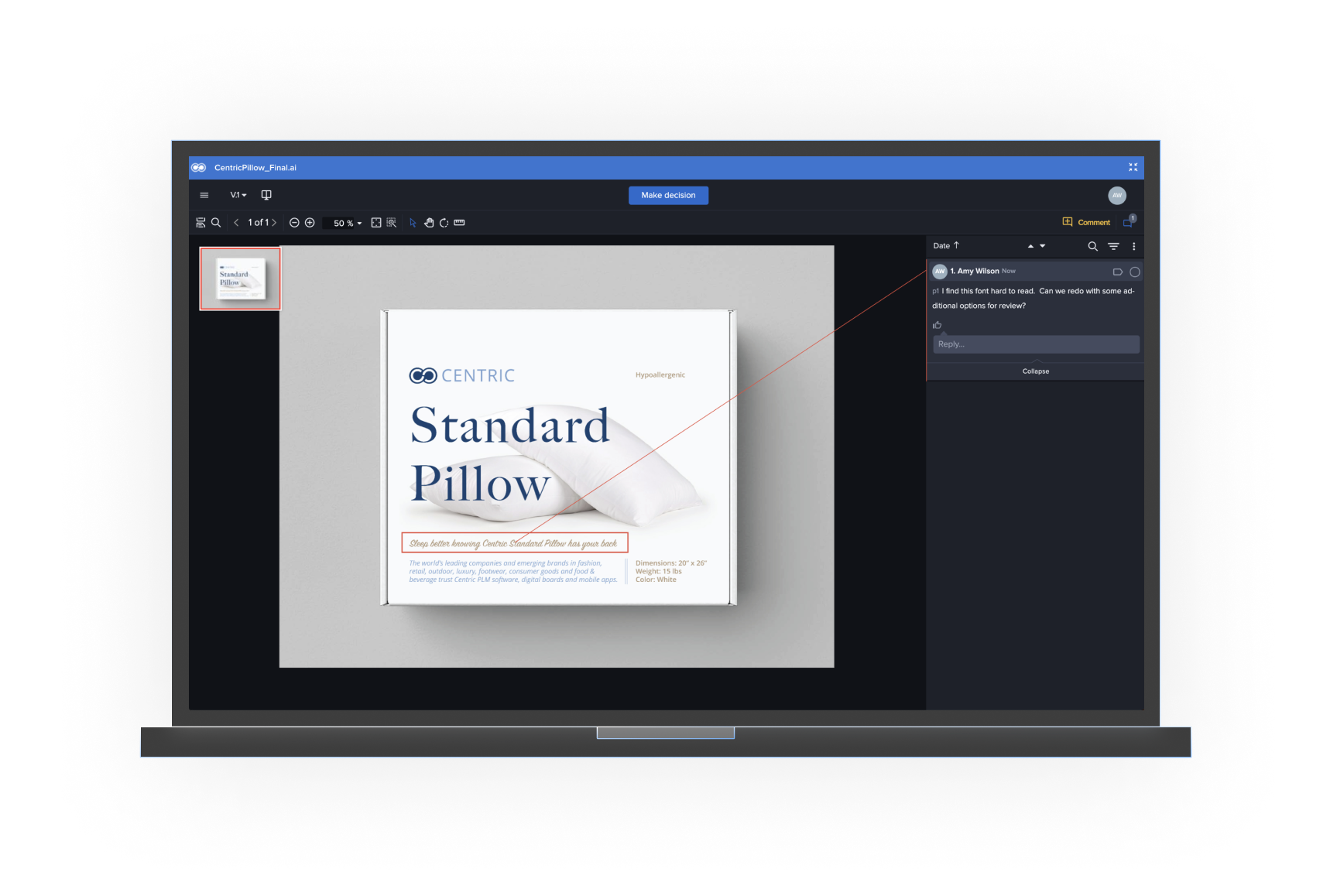

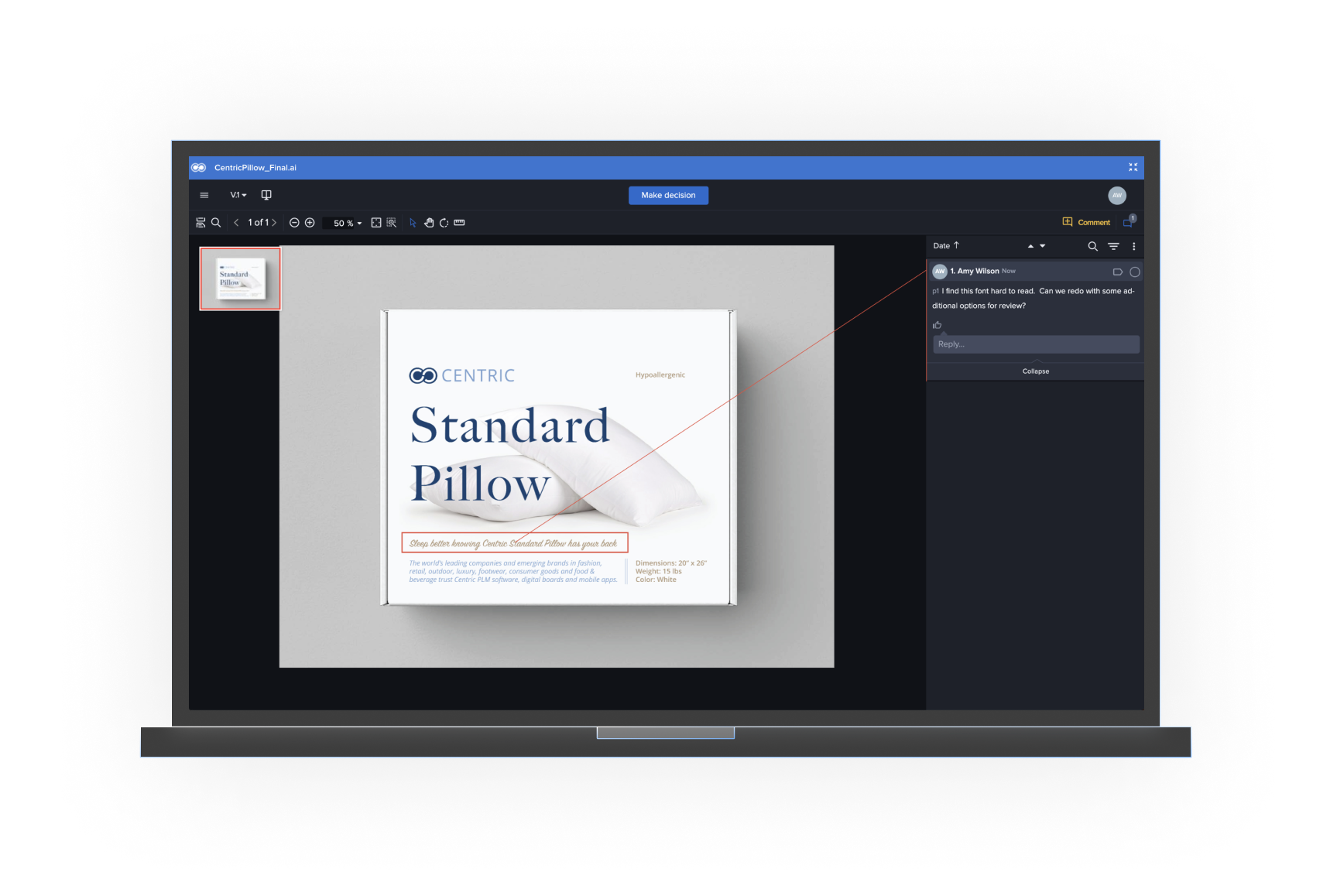

Packaging & Artwork

Connect your product packaging briefs directly to the product brief to increase efficiency and accuracy when developing new products

Simplified, cost-efficient approach to package and label development.

Track changes and automatically highlight version discrepancies to manage changing designs

Reviews and comment on 2D and 3D designs within PLM

Approval stage gates ensure nothing slips through the cracks

How do you use Centric PLM?

Manufacturing & Production

Align with brand and retail teams in a cloud-based digital environment for faster time to market

Manage all aspects of R&D, product development, costing and sampling

Respond to RFPs, build tech packs, handle quality testing, manage compliance documentation and more

Track compliance, sustainability and social impact, from raw materials to retail

How do you use Centric PLM?

Planning

Easily see priorities and manage accordingly

View holistically and collaborate on season planning

Know exactly where a product is in its lifecycle

Leverage data from past seasons to forecast demand and plan successful products

Build accurate reports quickly, based on up-to-date information

How do you use Centric PLM?

Merchandising

Manage seasons, departments, collections and specific styles to meet performance targets, using up-to-date information

Gain full visibility into material costs and product margins

Run dynamic what-if scenarios using live data from PLM and other enterprise solutions to make better decisions

Quickly create visual line plans and share information

How do you use Centric PLM?

Design

Eliminate or reduce manual tasks, freeing up time to focus on creativity

Stay in sync with merchandising and planning

Access material libraries and historical product data

Connect 3D design platforms with PLM to streamline product and packaging design

Co-create with suppliers and agencies using a single source of truth

How do you use Centric PLM?

R&D/Product Development

Simplify communication with one source of truth

Streamline private label and supplier co-created development

Eliminate duplicate data entry and time-consuming manual tasks

Increase efficiency and cross-team collaboration to drive innovation faster

How do you use Centric PLM?

Sourcing

Gain full visibility into material costs/product margins

Control flow of information while giving suppliers access to necessary data

Evaluate and rationalize your supplier base

Issue RFQs en masse and easily compare price quotes

Connect suppliers through the PLM supplier portal to improve collaboration

How do you use Centric PLM?

Quality

Manage quality control and inspections with mobile apps and templates directly connected to PLM that are accessible by all team members in real time

Facilitate supplier self-assessments and other third-party assessments using audit templates, mobile applications, and alert settings

Develop high-quality products that meet consumer expectations

How do you use Centric PLM?

Compliance

Maintain compliance documentation in a single, up-to-date digital location

Flag outliers and adapt rapidly to regulatory changes with change management

Track products throughout the complete lifecycle to manage traceability

Maintain data necessary to meet regulatory requirements and satisfy customers, such as sustainability credentials

How do you use Centric PLM?

Packaging & Artwork

Connect your product packaging briefs directly to the product brief to increase efficiency and accuracy when developing new products

Simplified, cost-efficient approach to package and label development.

Track changes and automatically highlight version discrepancies to manage changing designs

Reviews and comment on 2D and 3D designs within PLM

Approval stage gates ensure nothing slips through the cracks

How do you use Centric PLM?

Manufacturing & Production

Align with brand and retail teams in a cloud-based digital environment for faster time to market

Manage all aspects of R&D, product development, costing and sampling

Respond to RFPs, build tech packs, handle quality testing, manage compliance documentation and more

Track compliance, sustainability and social impact, from raw materials to retail

Planning

Merchandising

Design

R&D/Product Development

Sourcing

Quality

Compliance

Packaging & Artwork

Manufacturing & Production

Large or small, companies of all sizes and types drive digital transformation with Centric PLM

Centric PLM innovations empower companies to develop products more efficiently and sustainably.

From nimble DTC startups to long-established global brands expanding their omnichannel reach, our customers rely on Centric PLM to react with agility to market shifts and evolving consumer demand.

Brands

Retailers

Manufacturers & Producers

Direct to Consumer

Licensing & Private Label

Wholesalers

Emerging Brands

”When we generated our first tech pack there was this moment where everyone was really proud of what we’d accomplished. The tech packs are beautiful!”

Julia Handleman

Vice President of Design and Product Development

Seamlessly connect the value chain to boost innovation and launch market-right products on time.

Navigate supply chain complexity, collaborate with suppliers and streamline workflows to enhance competitiveness and creativity.

Drive sustainability initiatives and build consumer loyalty.

”The flexibility and best practices embedded in Centric PLM and the project’s Agile Deployment methodology enabled us to react quickly and gave us immediate visibility when the US made the decision to impose tariffs on Chinese goods.”

Ryan Shuster

Vice President of Global Sourcing

Retailers

Connect teams from assortment planning to merchandising to sourcing/product co-creation to boost omnichannel sell-through and meet consumer demand across branded and private label lines.

Develop and implement sophisticated retail strategies based on live data and what-if scenarios for minimal discounting and maximum sell-through.

”Across the board, the quality of information that Centric PLM now provides has improved almost everything we do.”

Eddie Li, Corporate IT Director, Tristate

Manufacturers & Producers

Power up productivity to reduce lead times and costs while maintaining product quality.

Drive product innovation and work more effectively with brand and retail partners and sub-contractors, reducing time-consuming manual work to boost speed, improve transparency/traceability and ensure compliance.

”There’s a great sense of comfort in having one place for product data and a digital workspace where we can collaborate faster, streamline communication, save time spent searching for information and analyze our progress.”

LAUREN TAFLINGER,

Director of Production, Rothy’s

Direct to Consumer

Deliver the exact products your customers want, at the right time and price, in a seamless buying experience.

Stop working with spreadsheets and cut time-consuming manual work to focus on innovation.

Connect with your e-commerce solution to adjust in-season based on sales and PLM data.

”During the first lockdown, we had an issue with our old PLM system where it basically went down on us. So completely remotely, both the Centric and Bioworld teams were able to spin up Centric, meeting our demand wholeheartedly.”

— Patrick Flanagan, IT Program Director at Bioworld

Licensing & Private Label

Manage and collaborate with licensing partners on a transparent, real-time ‘single source of truth’ product development platform that replaces spreadsheets and manual data entry.

Control licence documents and approvals, manage royalties and enhance overall communication, speed and accuracy.

”Our digital transformation with Centric Software enables us to remain competitive because of a considerable reduction in the time between the conception and sale of a product.”

THOMAS TCHEN

Founder and CEO

Lancaster

Wholessalers

Align strategic decision-making and execution based on reliable live data to develop product assortments efficiently for each channel, retailer and location.

Optimize collaboration to transform product development, sourcing, sell-in and sell-through.

”The data is all really easy to manipulate to give you the perfect report that your executive team is looking for.”

Kalin Mowry

Director of Production and Development

Emerging Brands

Get access to the same technology and industry know-how as global brands, and watch your business grow.

Build a strong digital foundation that will scale and evolve with you to speed product development, increase profitability and boost efficiency.

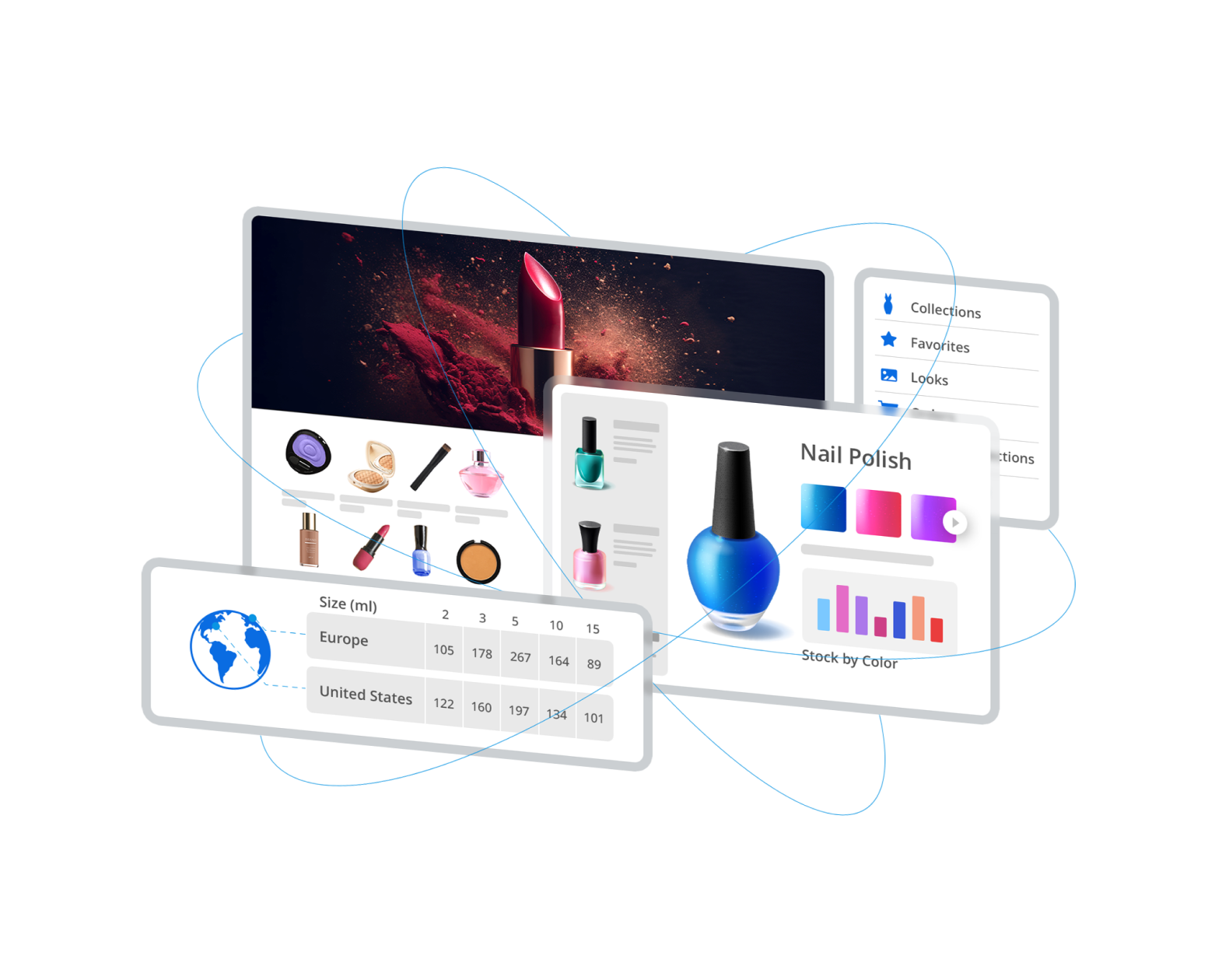

Centric PLM is a flexible, modular solution that optimizes all aspects of product ideation, development and launch.

Fashion & Apparel

Home & Furniture

Multi-Category Retail

Food & Beverage

Consumer Electronics

Cosmetics & Personal Care

Change Your industry Selection

Line Planning

Centric Fashion Inspiration

Product Specifications

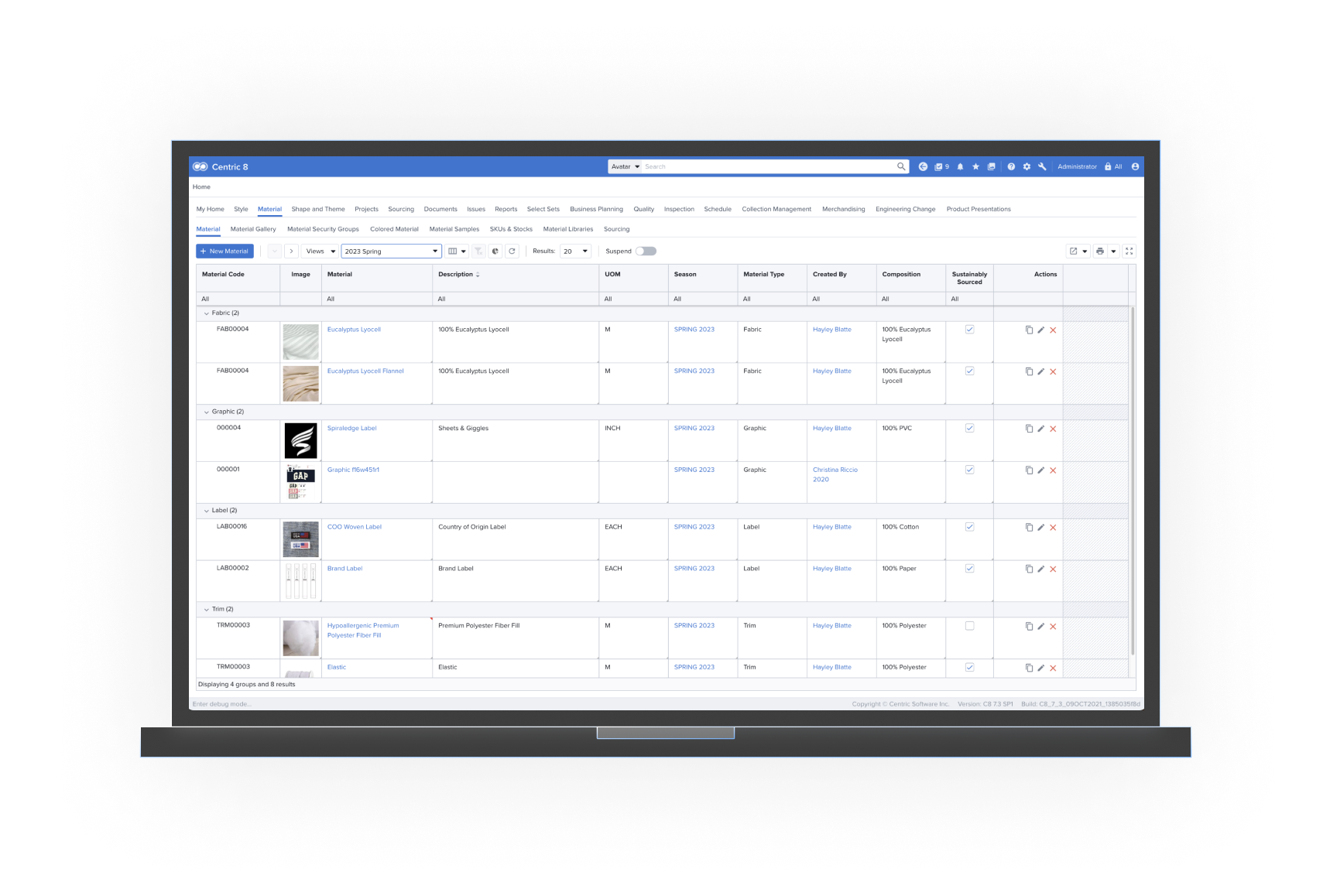

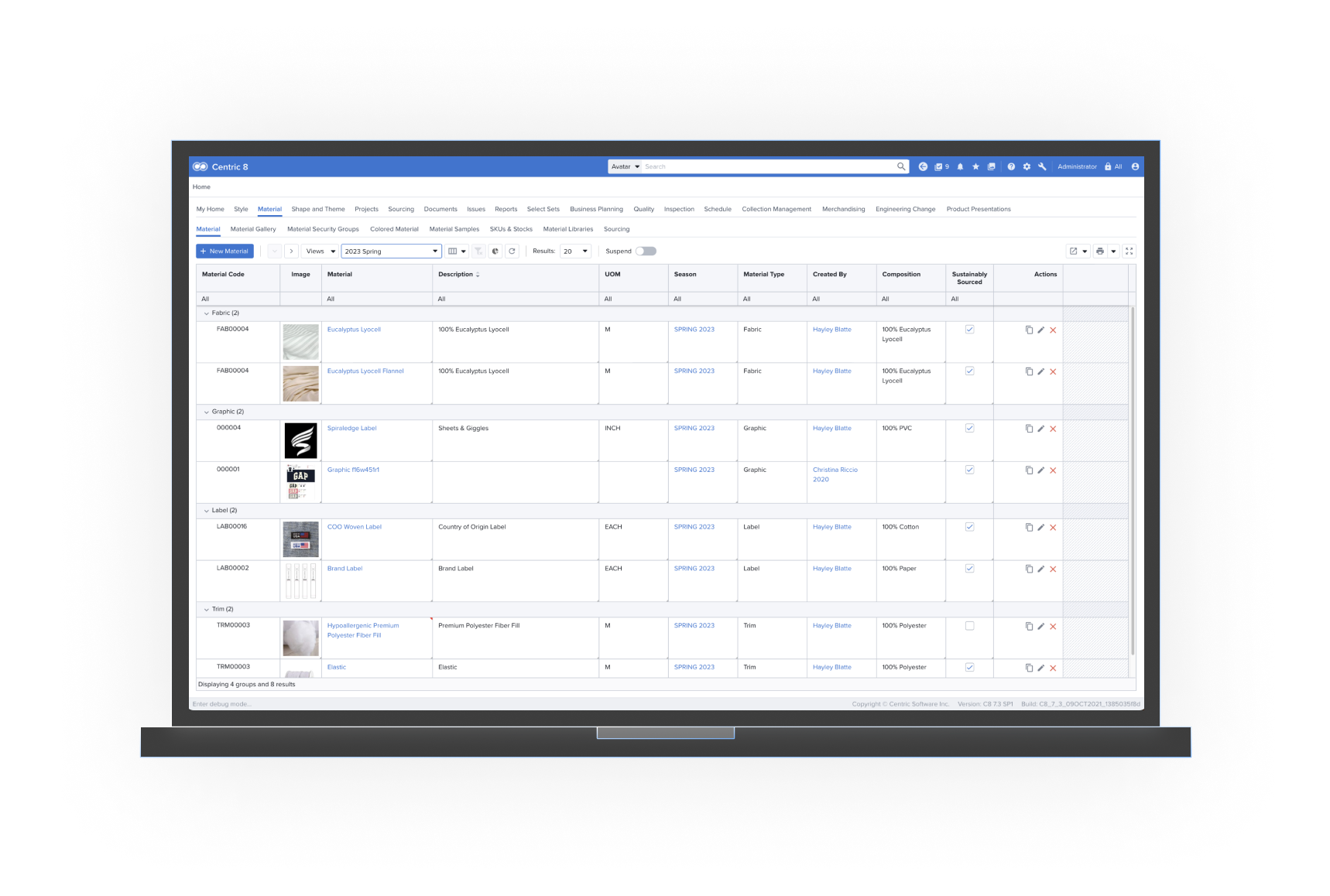

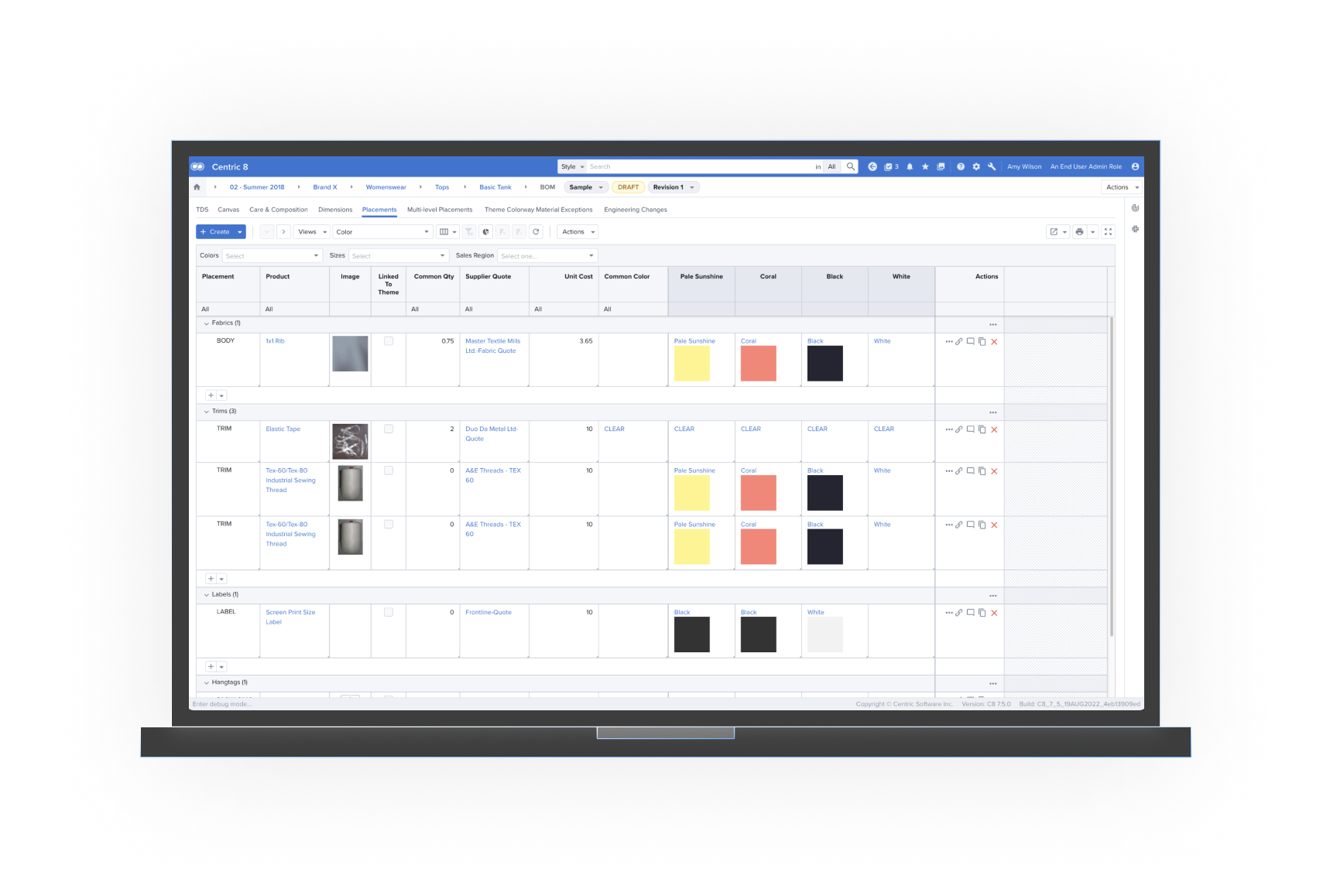

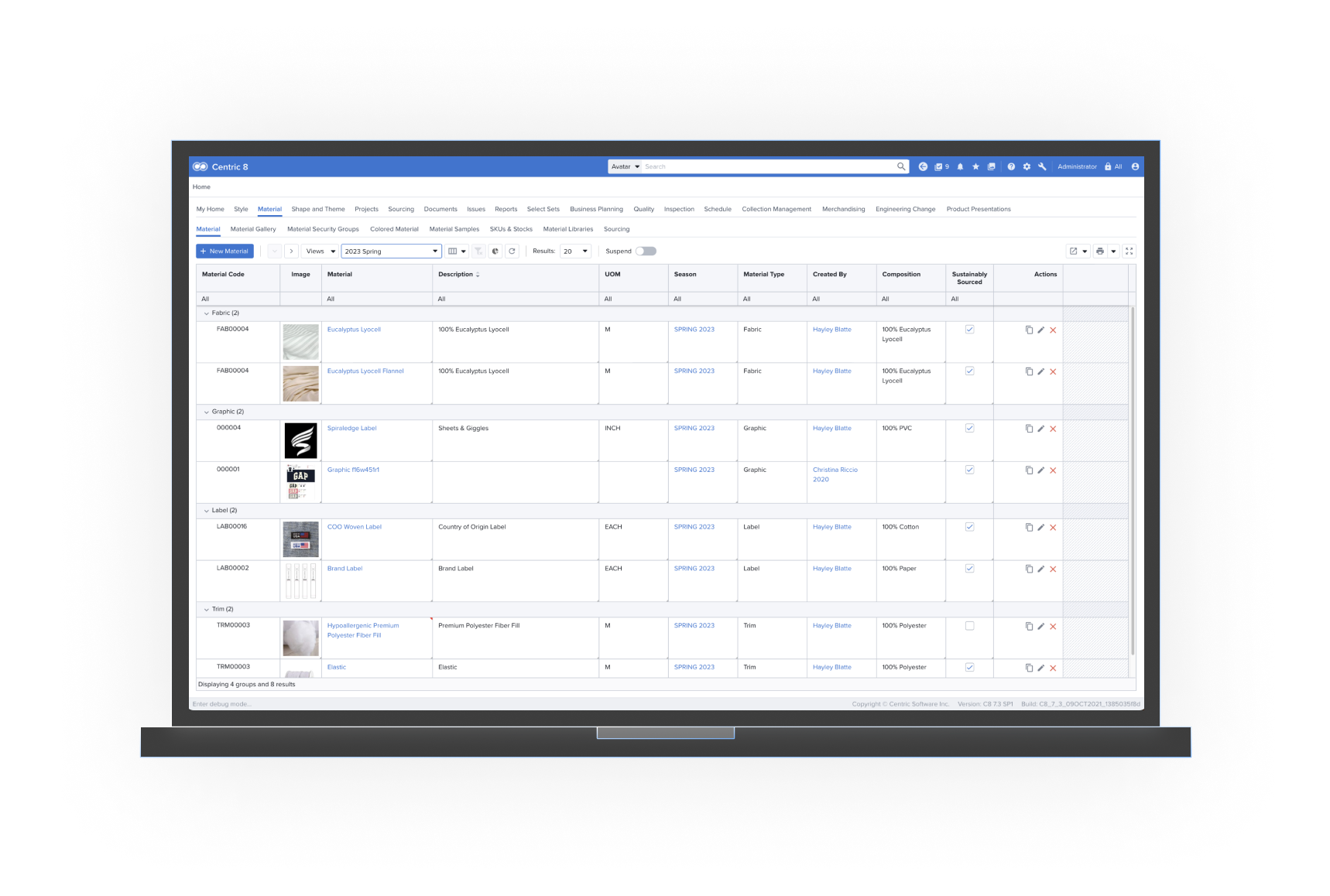

Materials Management

Product Sourcing

Calendar Management

Quality Management

Final Inspection

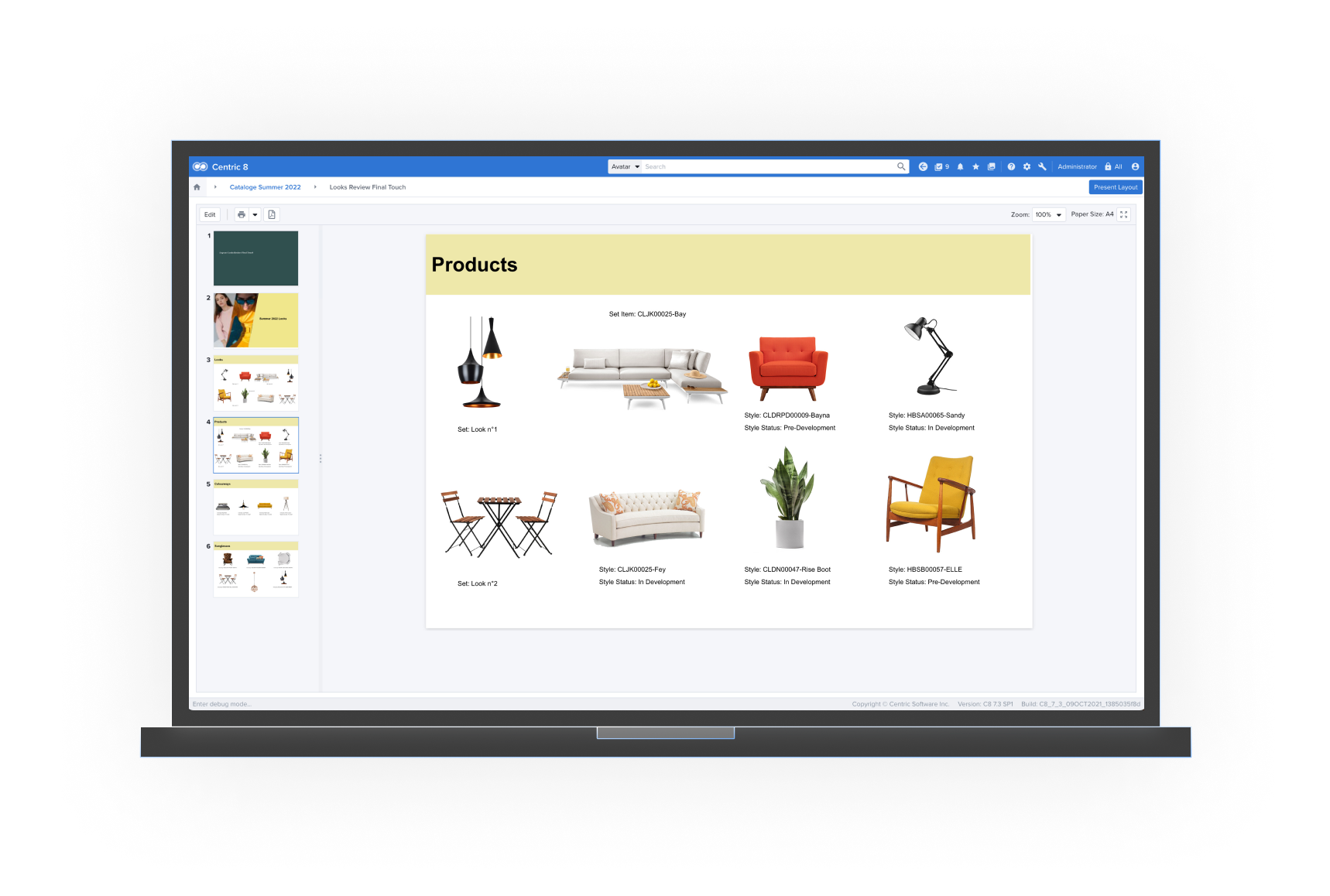

Product Presentations

Visual Assortment Board for PLM

Visual Concept Board

Visual Sourcing Board

Visual Omnichannel Showroom Board

Proofing

Process Management

Line Planning

Product Specifications

Materials Management

Product Sourcing

Calendar Management

Quality Management

Final Inspection

Proofing

Process Management

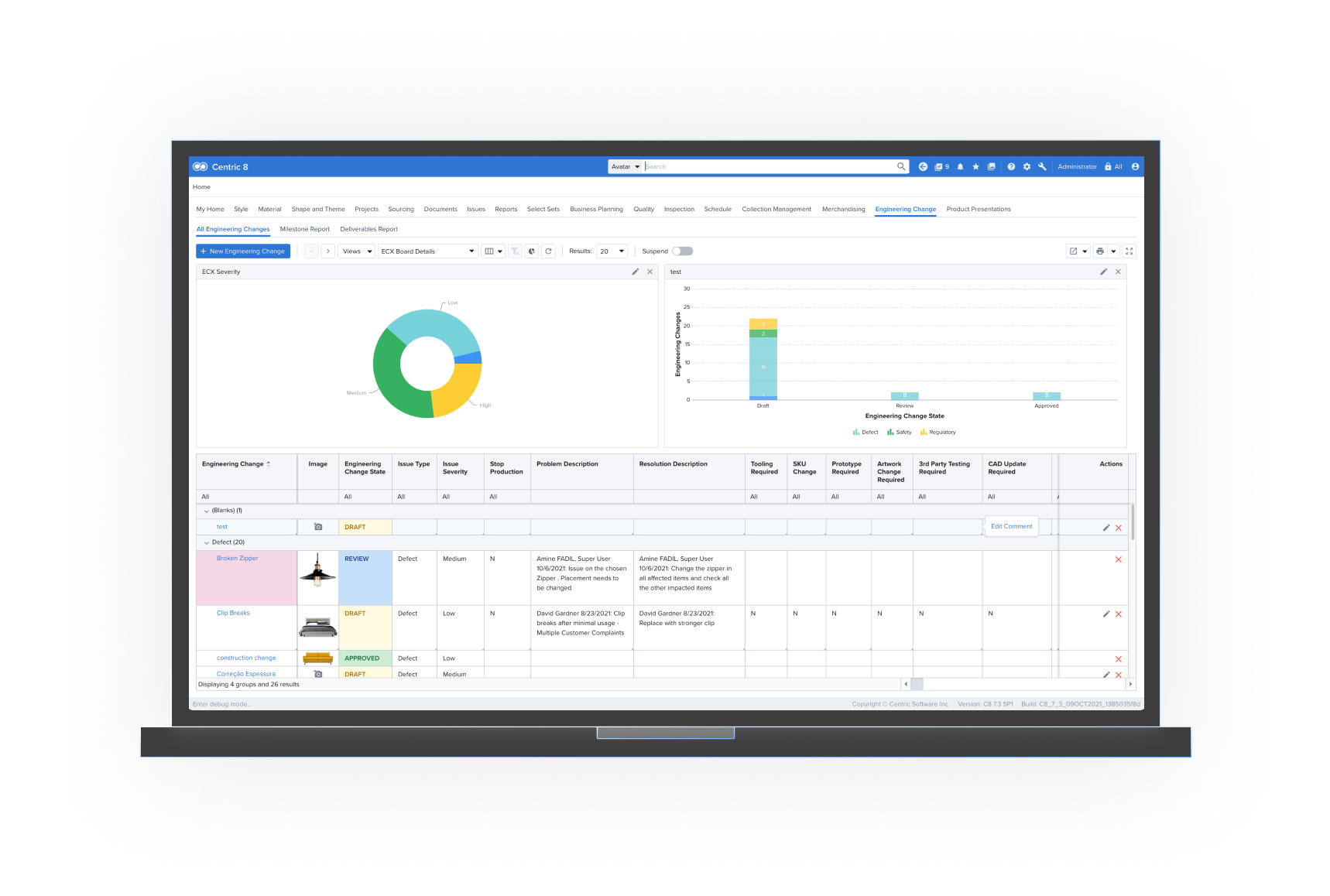

Engineering Change

Visual Assortment Board for PLM

Visual Concept Board

Visual Sourcing Board

Visual Omnichannel Showroom Board

Retail Review

Line Planning

Product Specifications

Materials Management

Product Sourcing

Calendar Management

Quality Management

Final Inspection

Proofing

Process Management

Engineering Change

Product Presentations

Visual Assortment Board for PLM

Visual Concept Board

Visual Sourcing Board

Visual Omnichannel Showroom Board

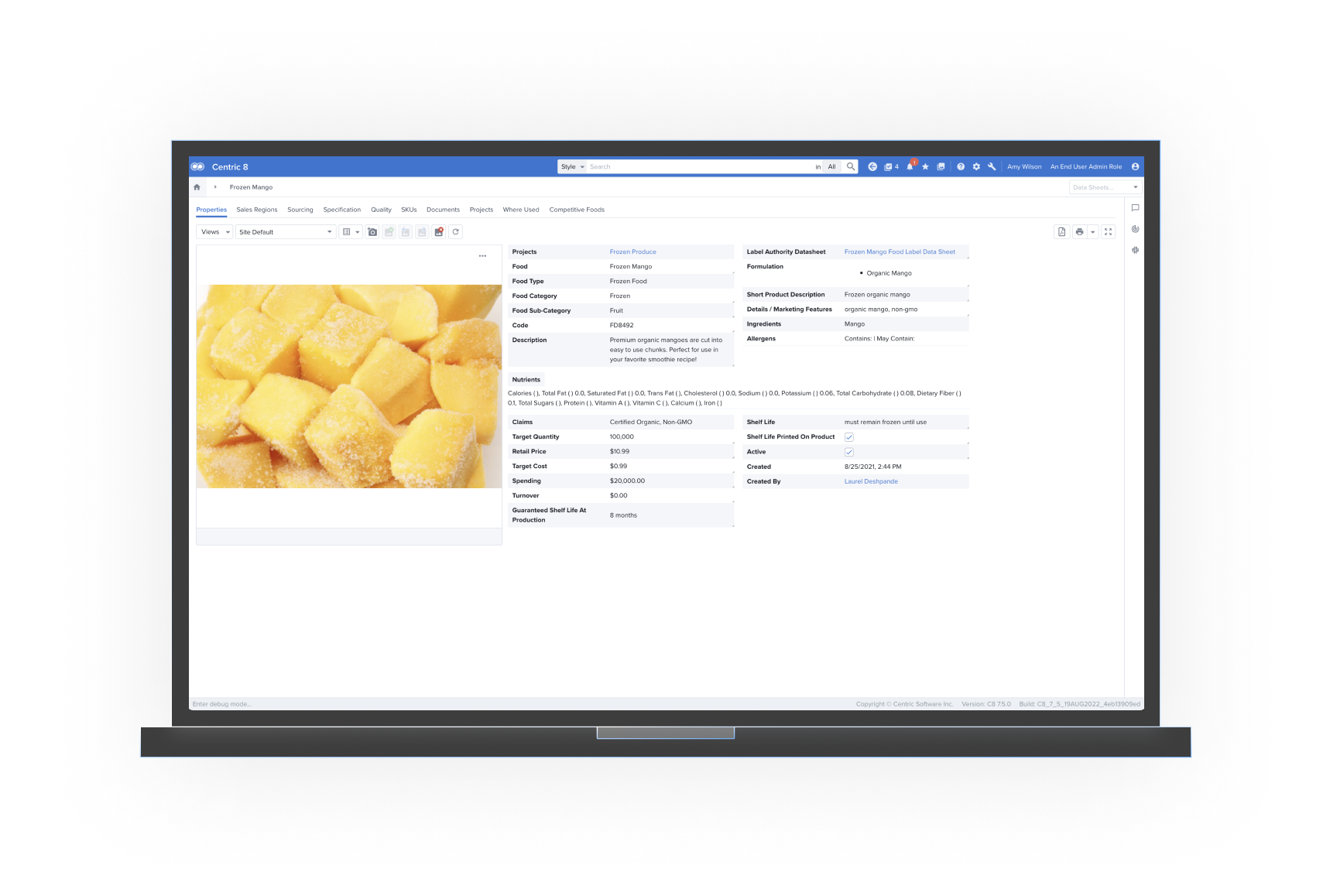

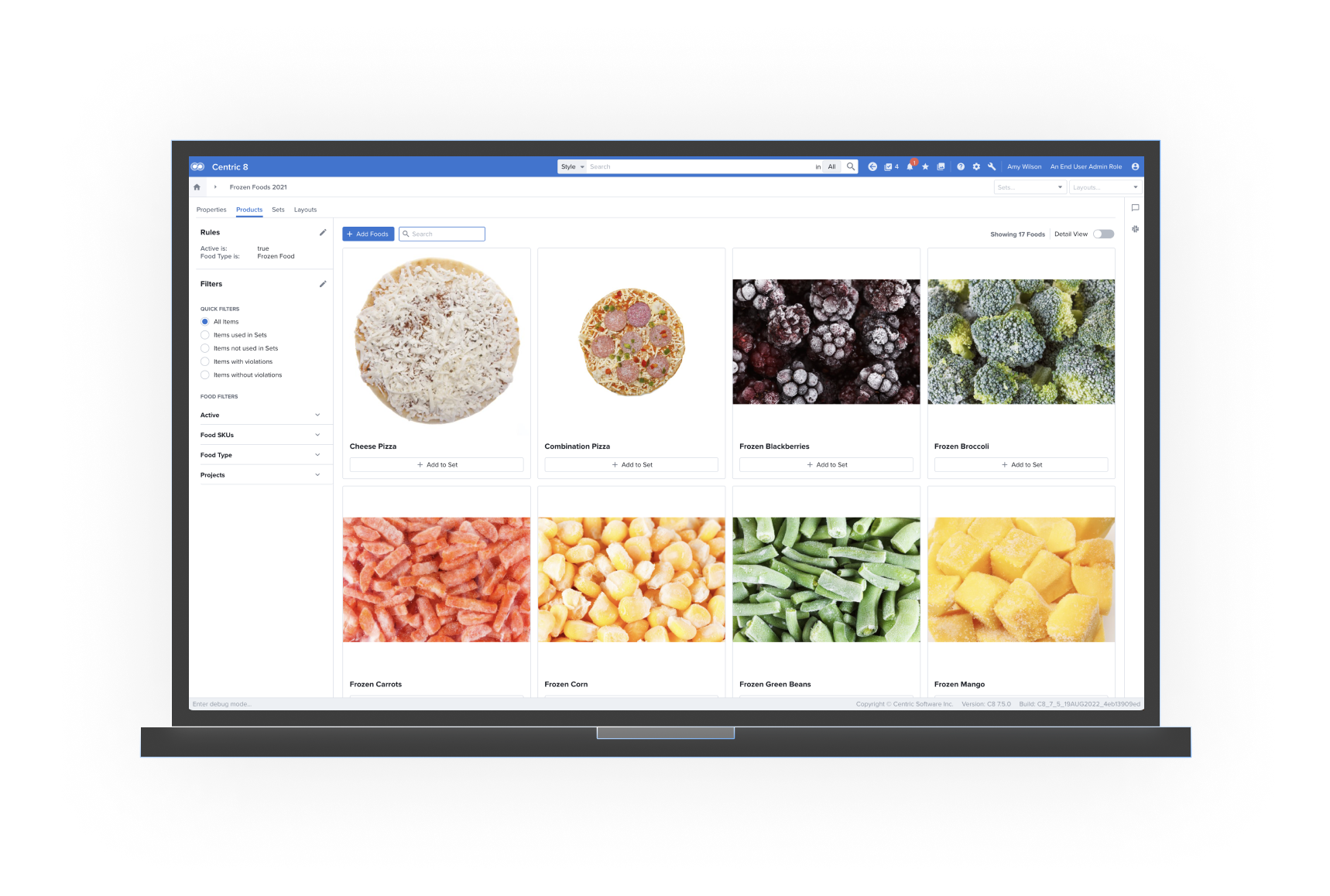

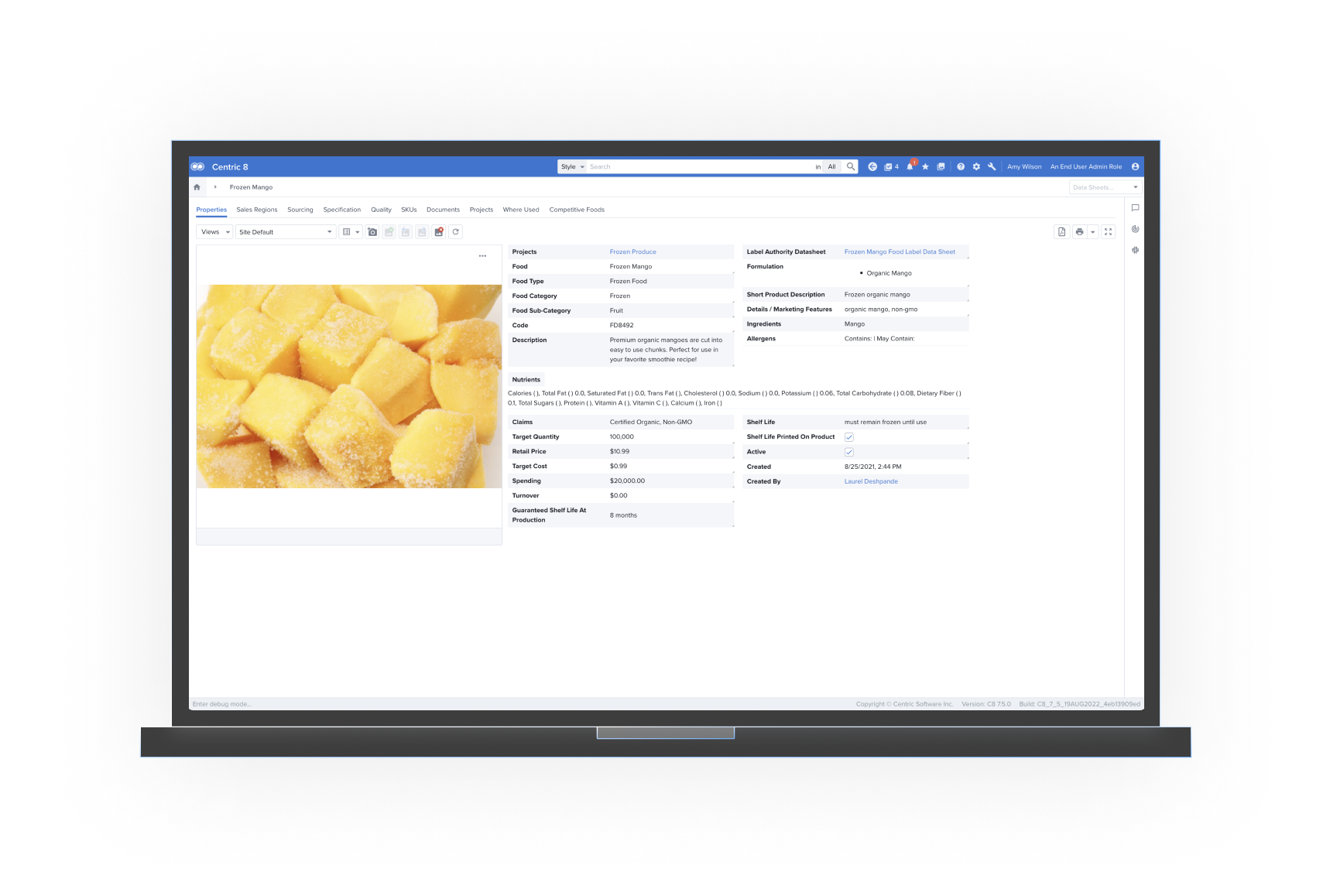

Centric PLM Base

Product Specifications

Recipe & Formulation

Product Sourcing & Costing

Change Management

Packaging & Artwork

Project Management

Quality & Compliance

Portfolio & Merchandise Planning

Product Presentations

Visual Assortment Board for PLM

Visual Concept Board

Visual Sourcing Board

Visual Omnichannel Showroom Board

Merchandise Planning

Product Specification & Proofing

Component and Material Management

Product Sourcing

Engineering Change Control

Calendar Management

QMS & Compliance

Process Management

Visual Assortment Board for PLM

Visual Concept Board

Visual Sourcing Board

Visual Omnichannel Showroom Board

Centric PLM Base

Product Specifications

Trials & Formulation Management

Product Sourcing & Costing

Change Management

Packaging & Labeling

Innovation & Project Management

Compliance & Quality Management

Portfolio & Merchandise Planning

Product Presentations

Visual Assortment Board for PLM

Visual Concept Board

Visual Sourcing Board

Visual Omnichannel Showroom Board

Line Planning

Orchestrate seasons, departments, collections and product lines to meet performance targets.

Flexible analytics use always up-to-date product information to aid in the creation of top-down goals and bottom-up estimates. Fully align collection development with financial planning, generate realistic sales forecasts, easily identify outliers that impact performance, and make decisions with confidence based on data, not “guesstimates.”

Centric Fashion Inspiration

Explore limitless design options with Centric Fashion Inspiration™, an AI-powered solution for fashion, outdoor, footwear and accessory brands. Trained on over 10 years of fashion imagery and integrated with Centric PLM™, this tool accelerates ideation, boosting teams to bring trend-driven products to market faster. With access to 1,000+ attributes across 800+ categories, including colors, patterns, materials, styles and more, design teams can quickly generate on-trend concepts. Seamlessly integrated with the PLM workflow, it enables non-designers like buyers and merchandisers to collaborate effectively, ensuring a continuous flow of fresh ideas that meet consumer demand.

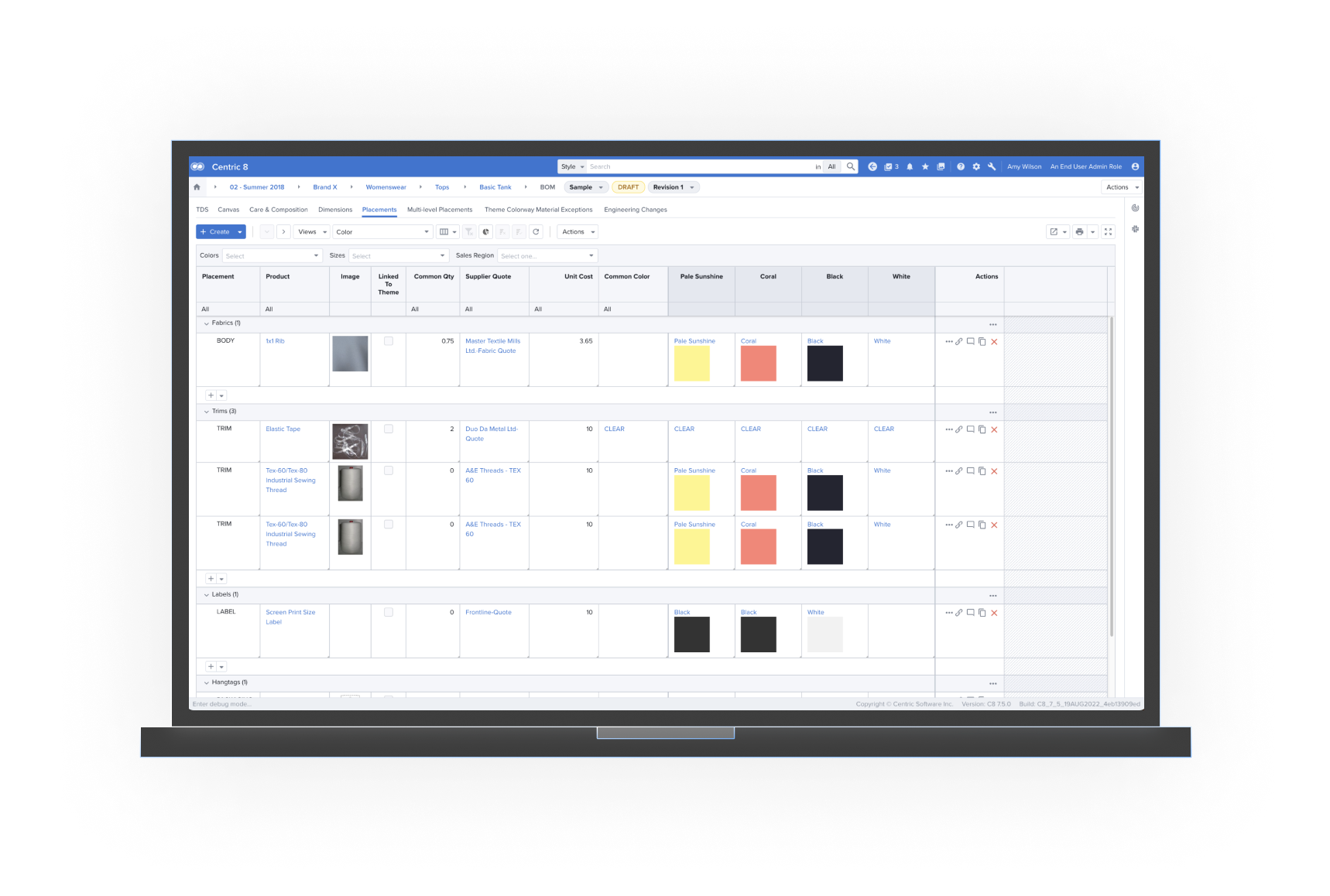

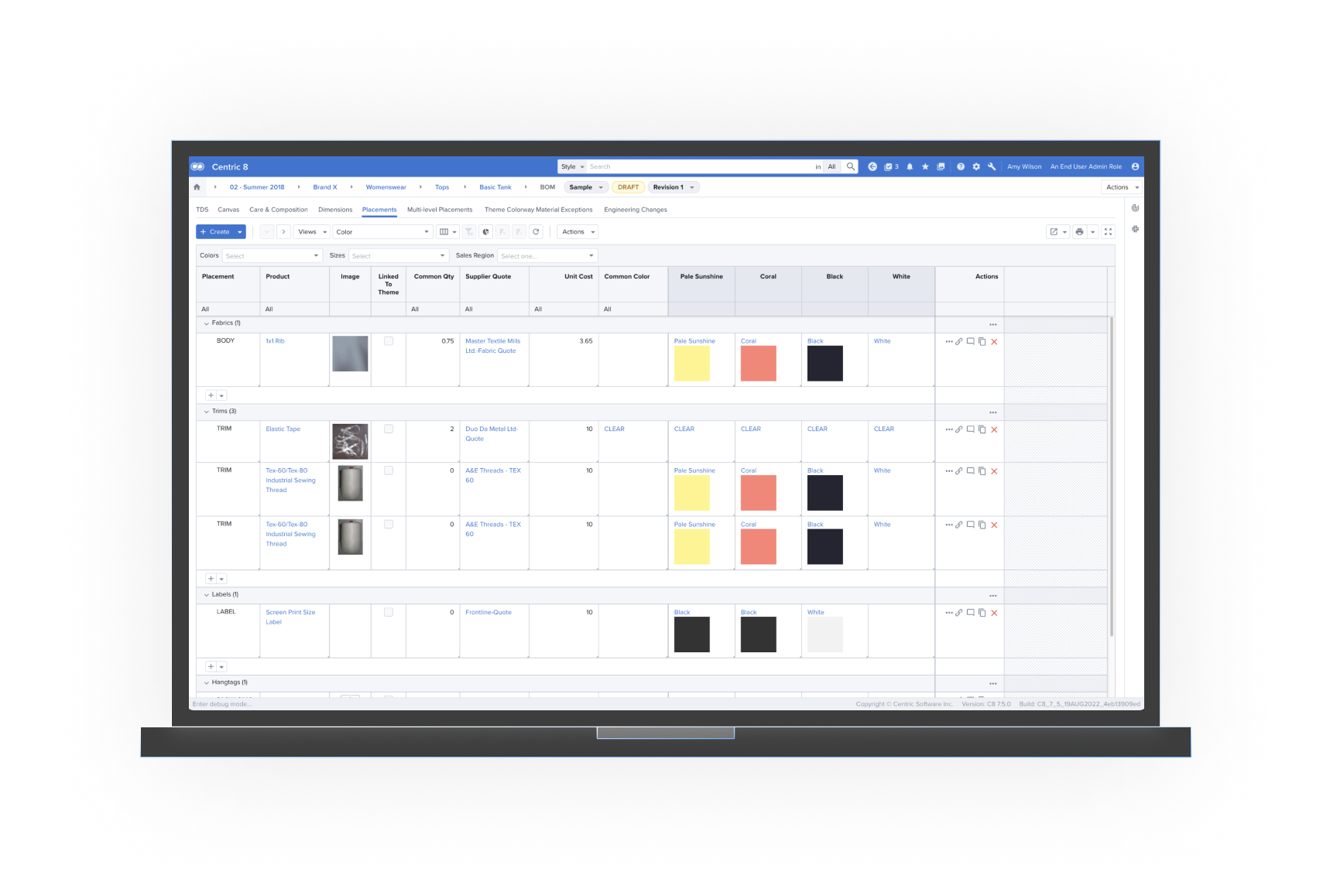

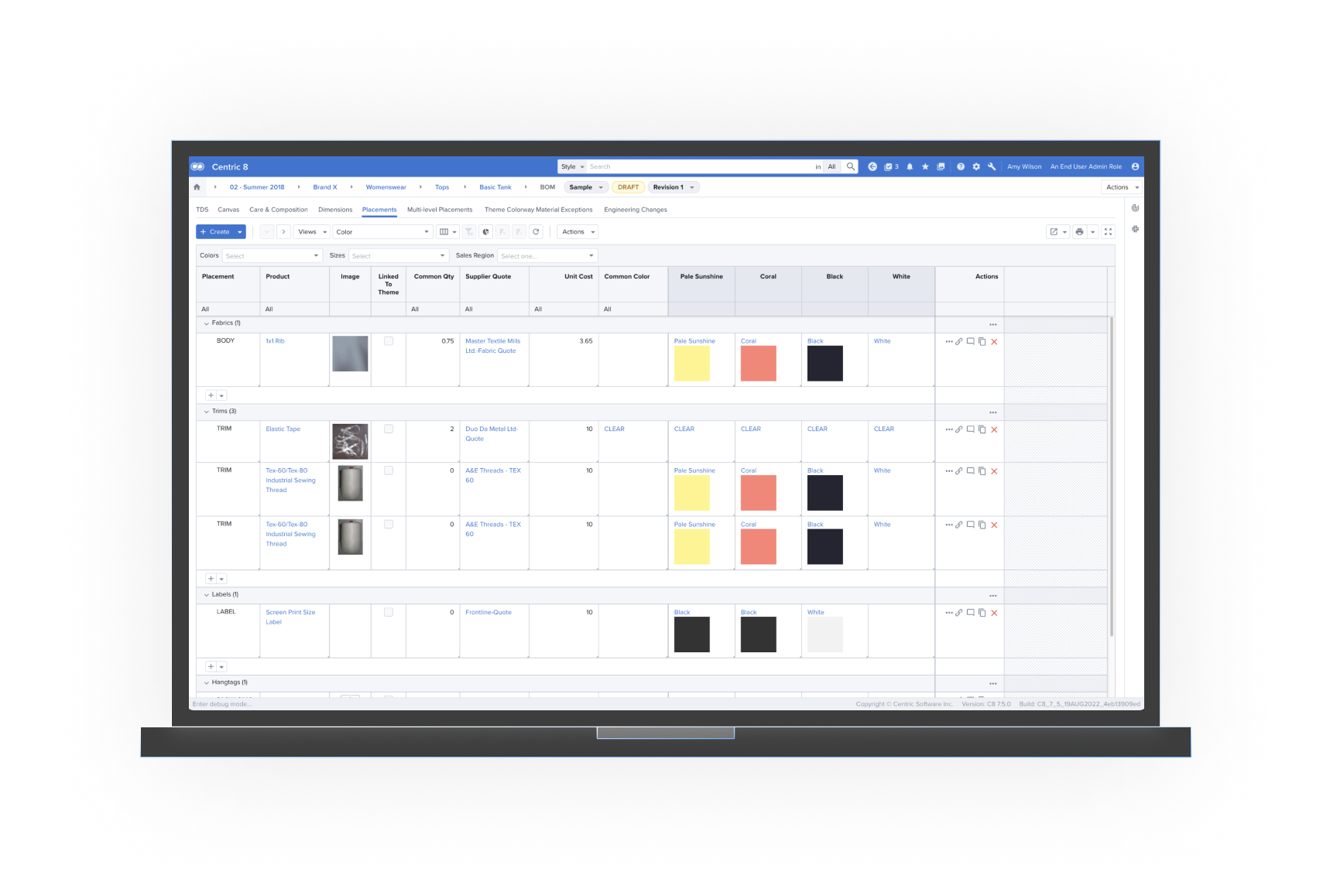

Product Specifications

Easy-to-use interface to create and manage multiple product, raw material and packaging specifications.

Communicate specifications effectively to minimize iterations, errors and costs. Track product lifecycle changes and coordinate with all development teams so that designers, technical designers and/or product developers can do their jobs easily and efficiently.

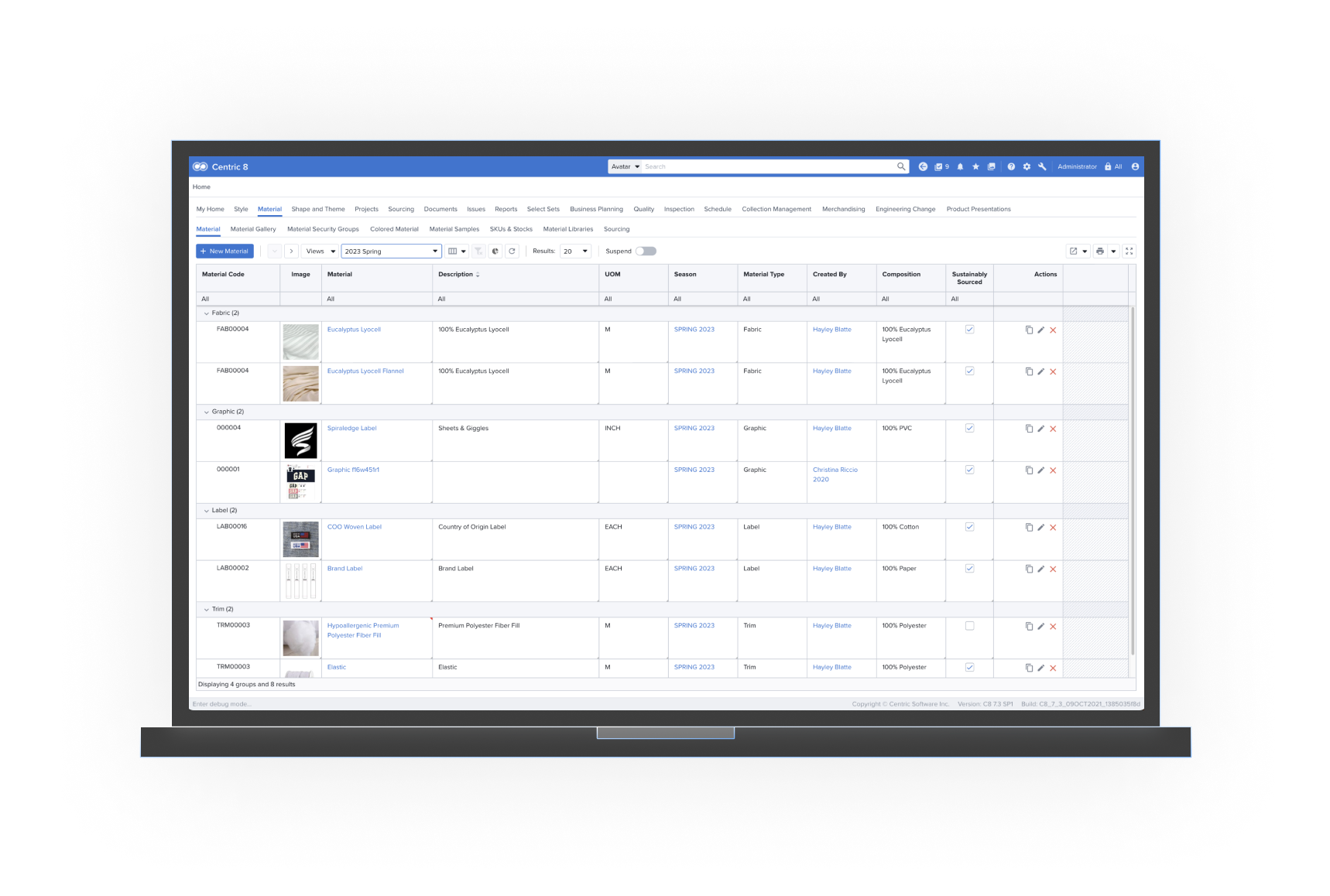

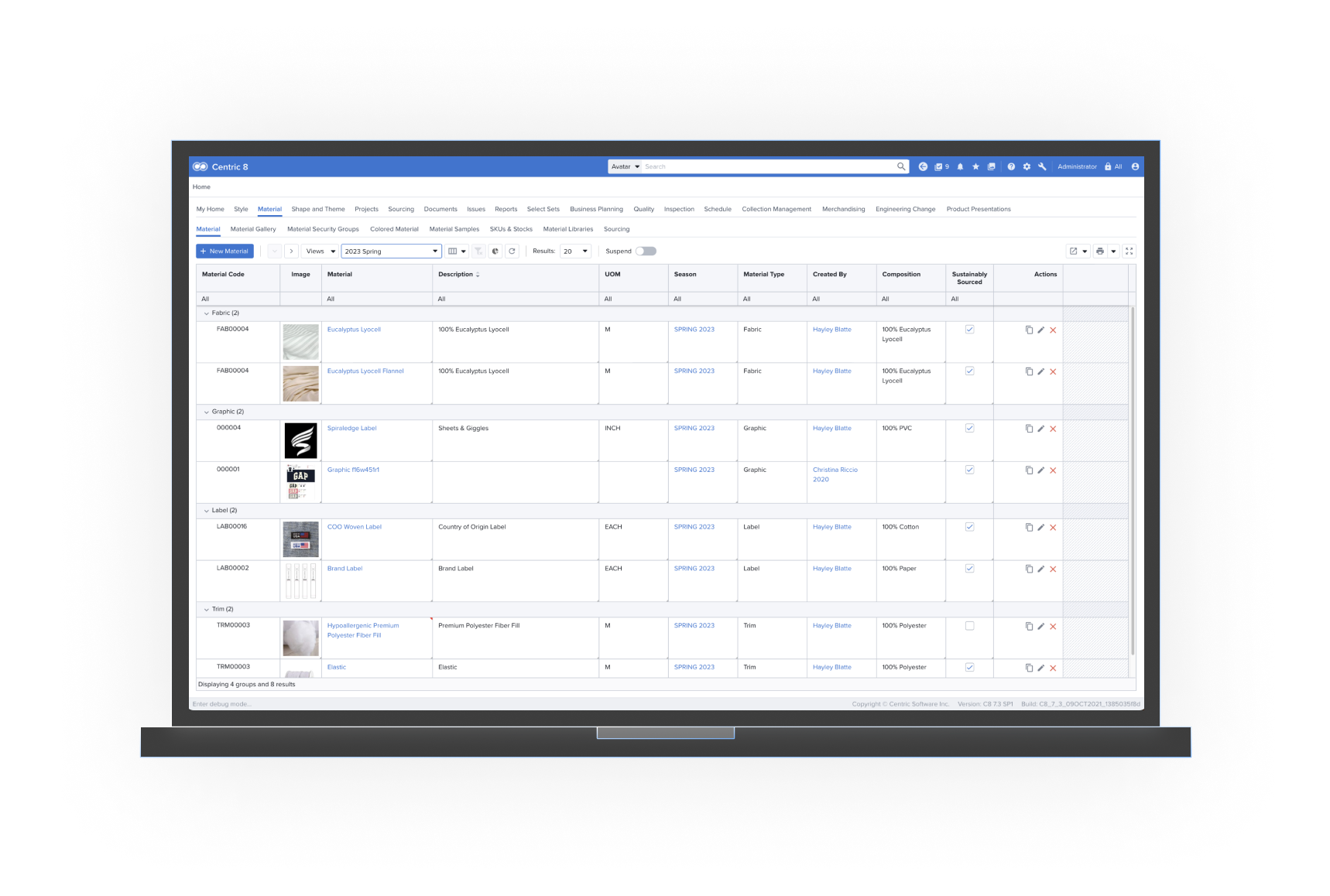

Materials Management

Empower traceability with the ability to track material usage and view the entire lifecycle of a material prior to use in a product.

Manage the process of developing and using simple and complex materials. Analyze trends and manage changes by rolling up information from style to material for reporting, or initiating changes from materials to multiple styles.

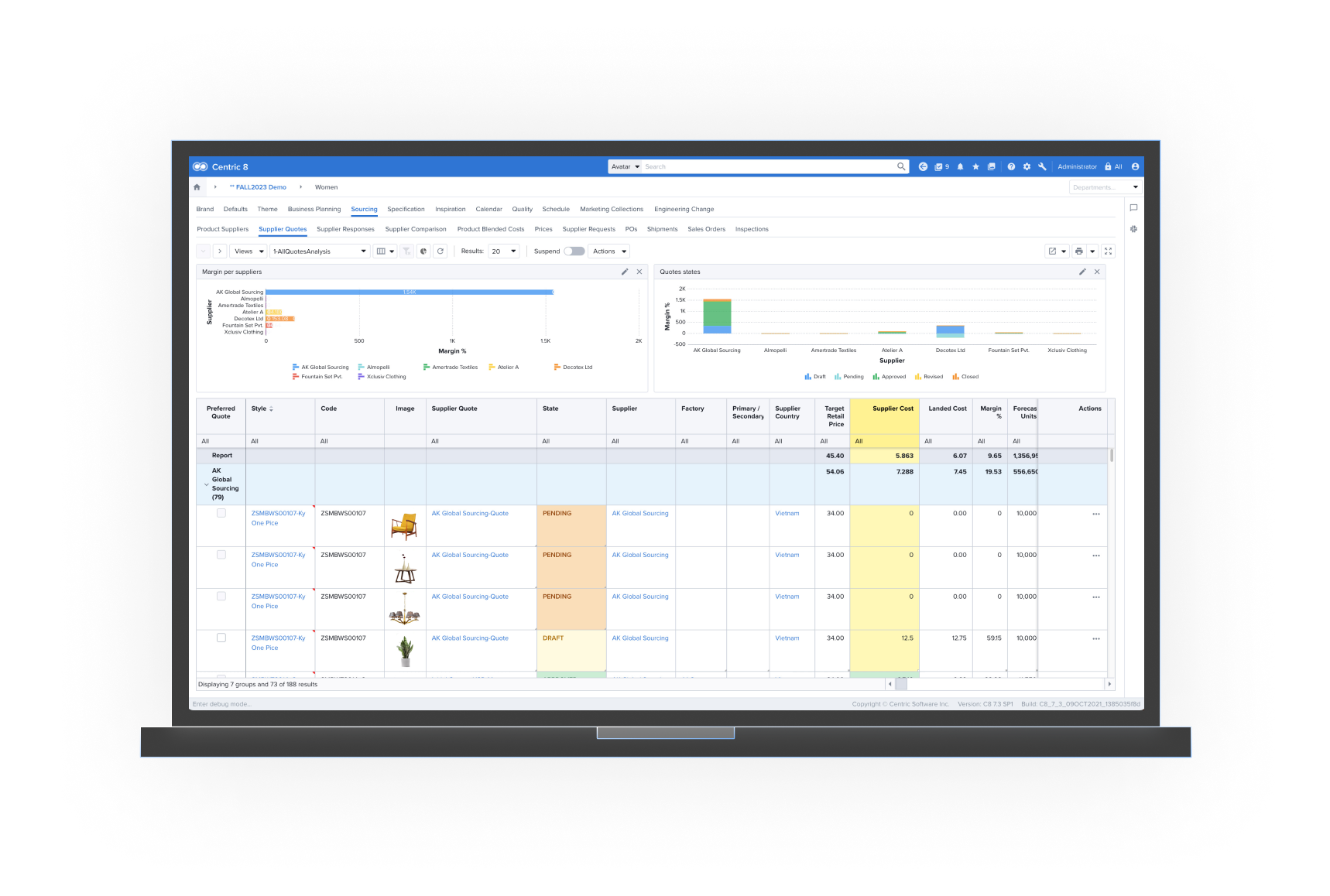

Product Sourcing

Connect sourcing teams and suppliers with Centric PLM, streamline communication and access vendor information.

Handle all aspects of sourcing, from selecting suppliers to managing samples and prototypes to negotiating purchase orders. Manage supplier sustainability certifications, track supplier-quoted costs, send RFQs en masse and easily compare quotes.

Calendar Management

Gain full visibility of timelines and manage tasks, deadlines and workflow across teams.

Configure templates to track products against target deadlines and give users visibility into where a product is in its lifecycle as activities are completed, keeping teams on track and enabling greater transparency, collaboration and planning.

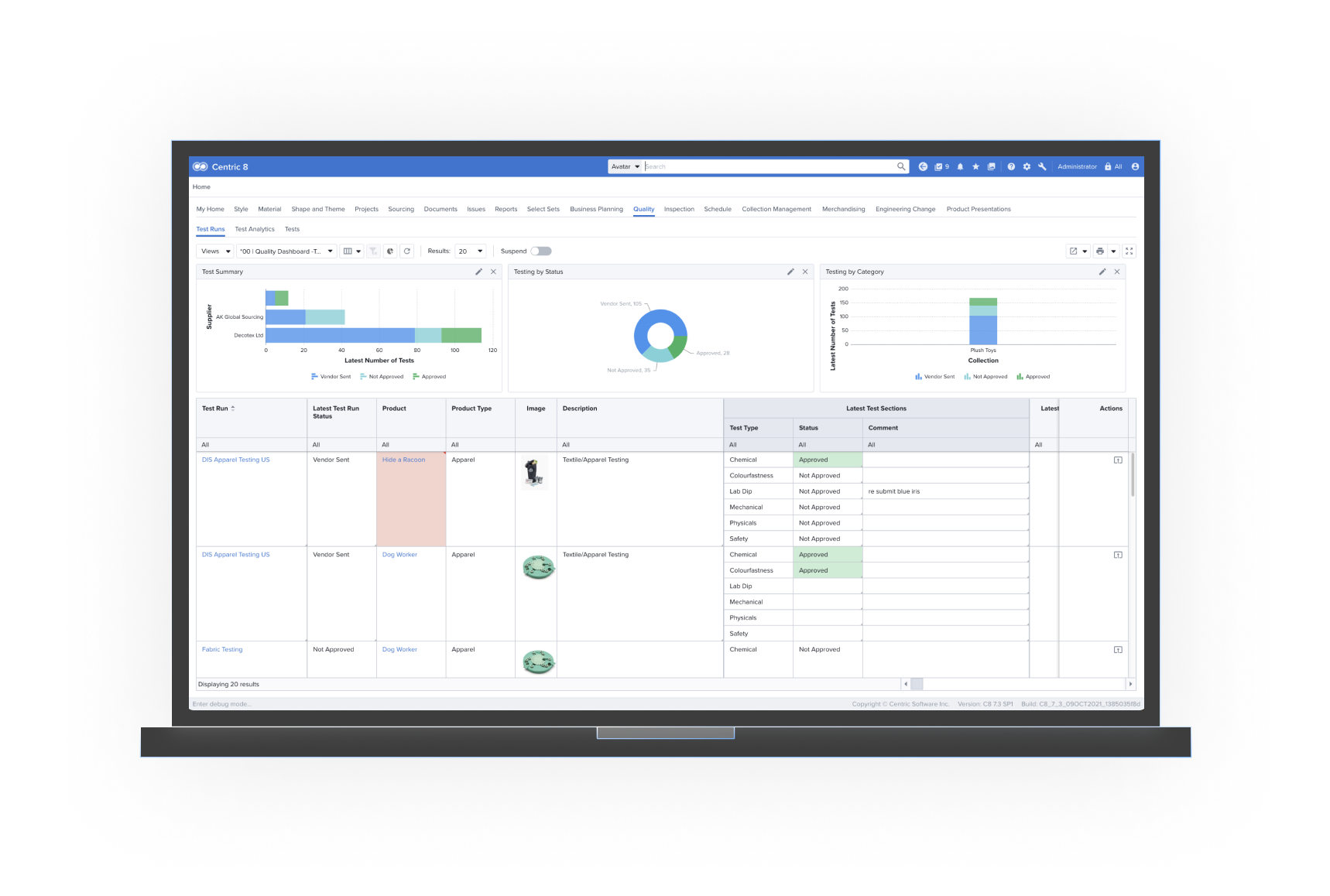

Quality Management

Assign quality and safety goals based on both corporate standards as well as channel-specific standards.

Define quality assurance, performance and mechanical tests on products to eliminate quality issues. Specify third party testing standards and track testing completed on materials and samples/styles to enhance quality, brand reputation and consumer loyalty.

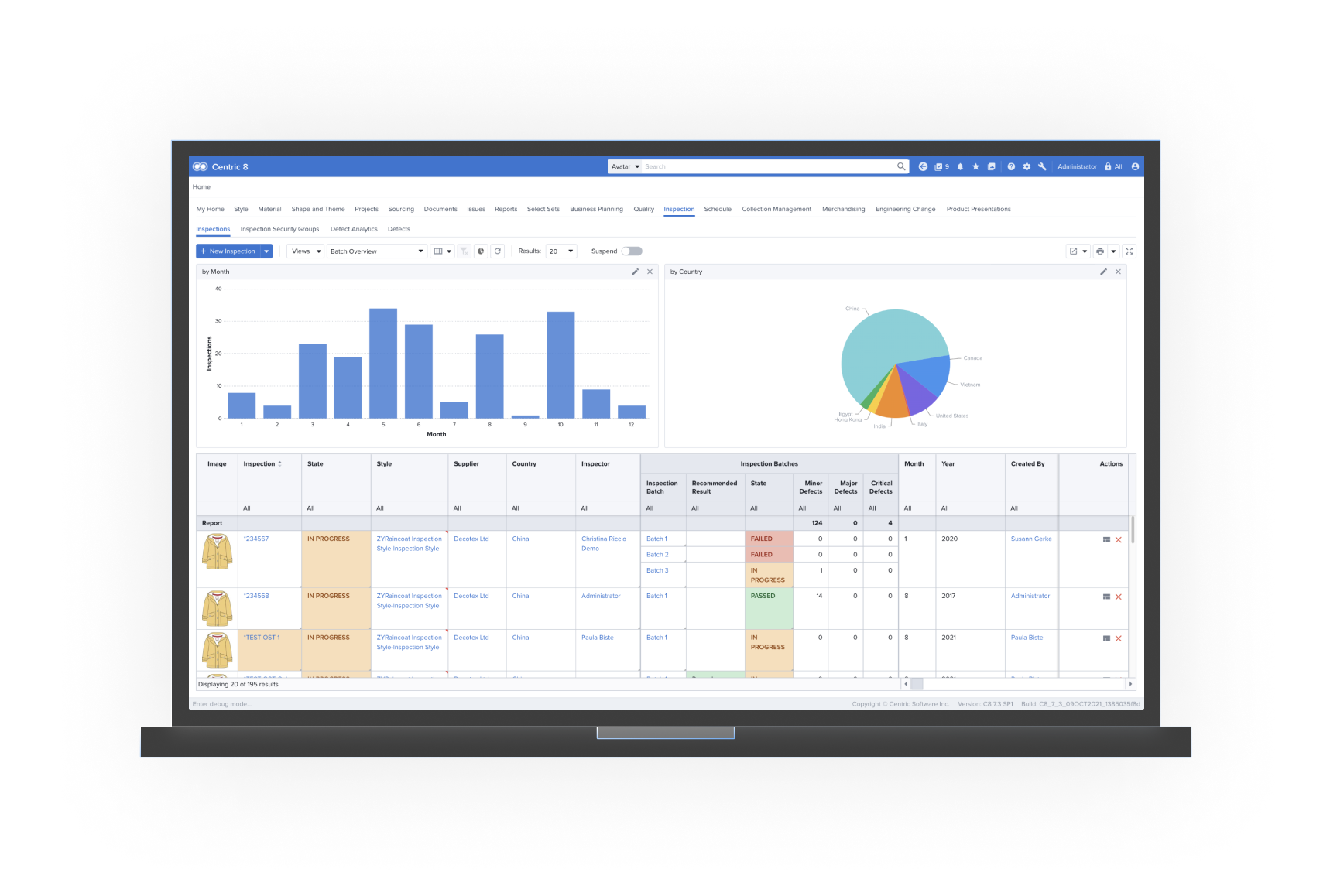

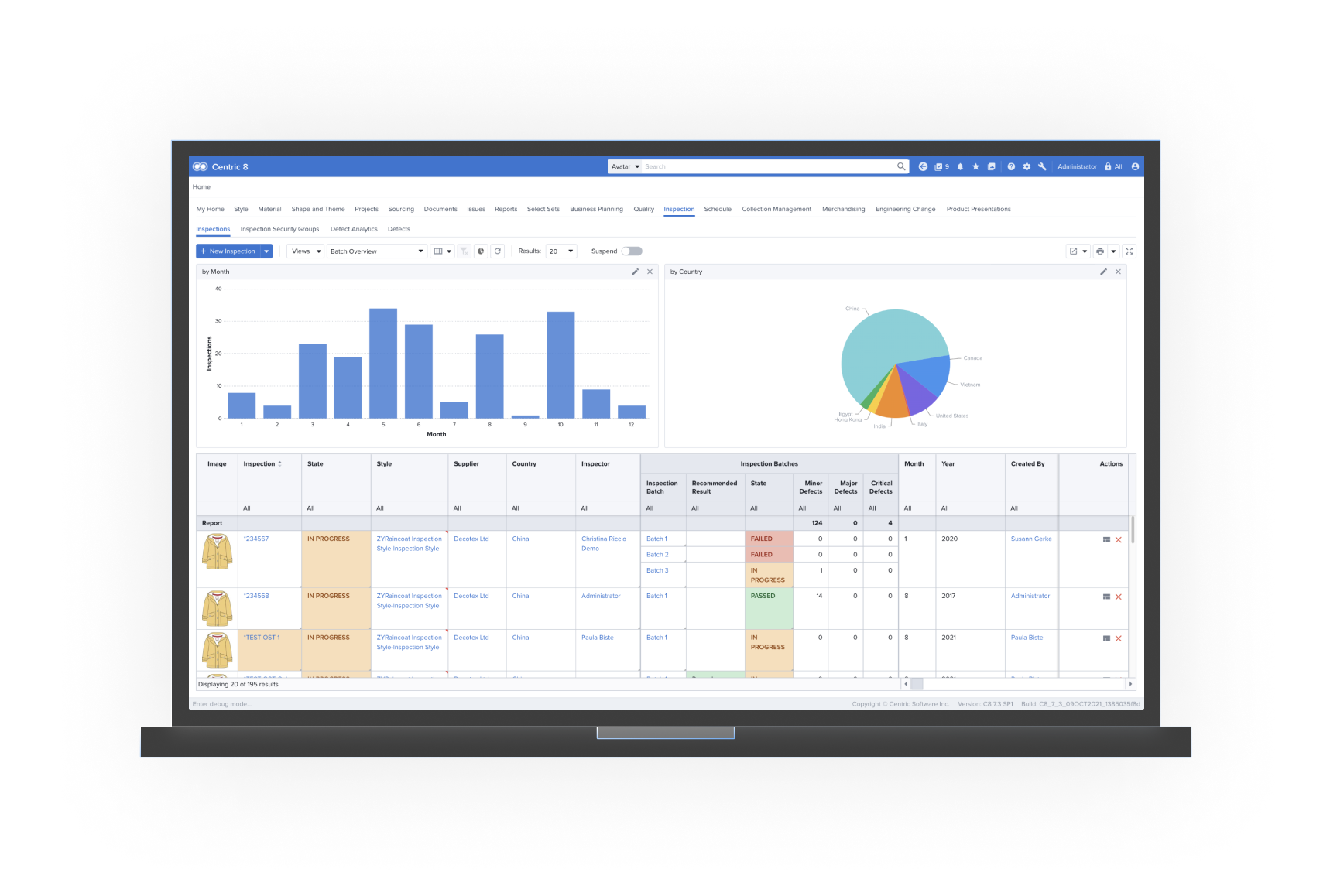

Final Inspection

Expand the power of PLM into production with complete, real-time transparency into both vendor performance and production output.

Final Inspection enables brands and retailers to set acceptable quality levels and evaluation points for suppliers on a per product basis, linked to original product specifications. Evaluation criteria and results are communicated digitally prior to goods leaving the manufacturing site and transfer of ownership.

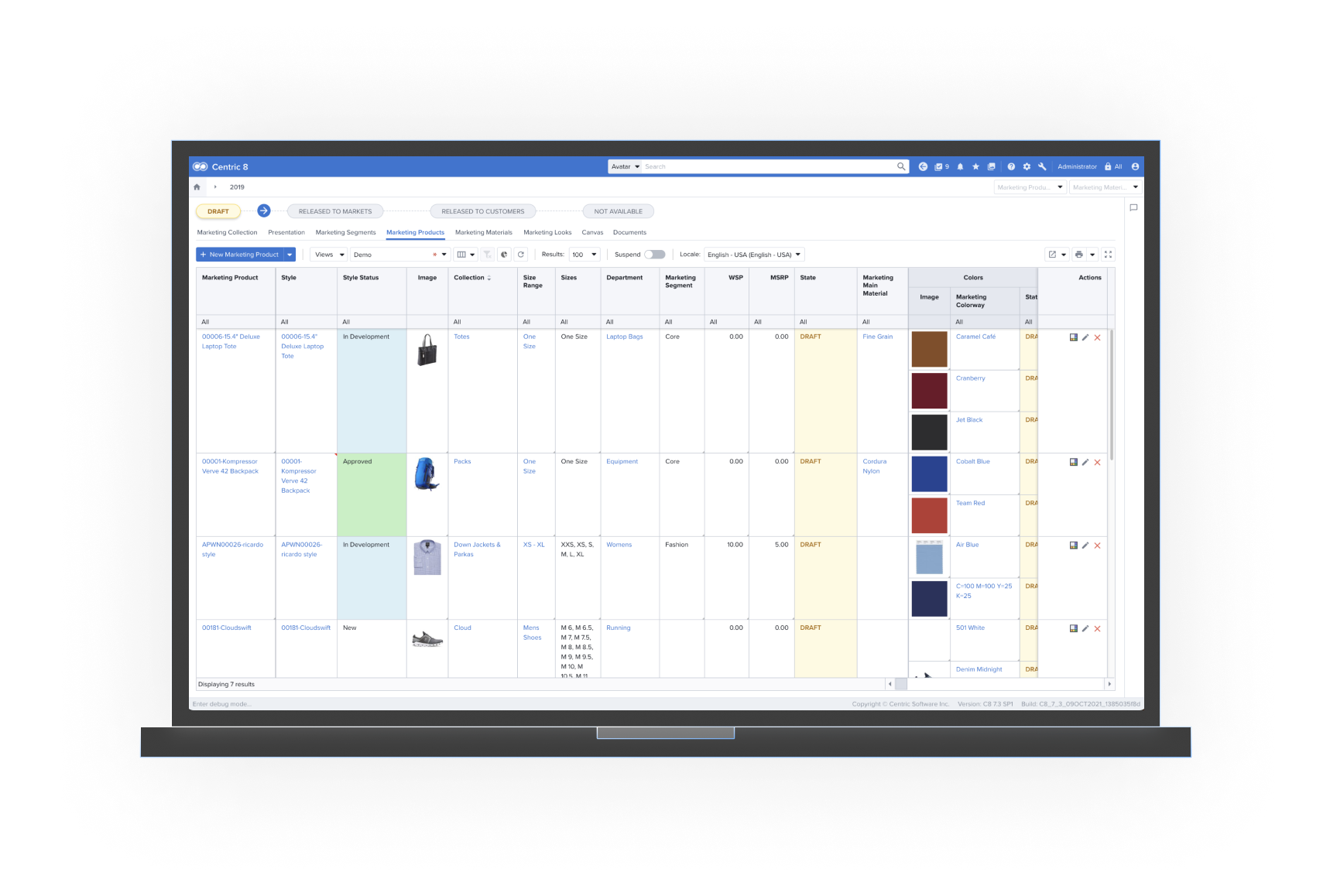

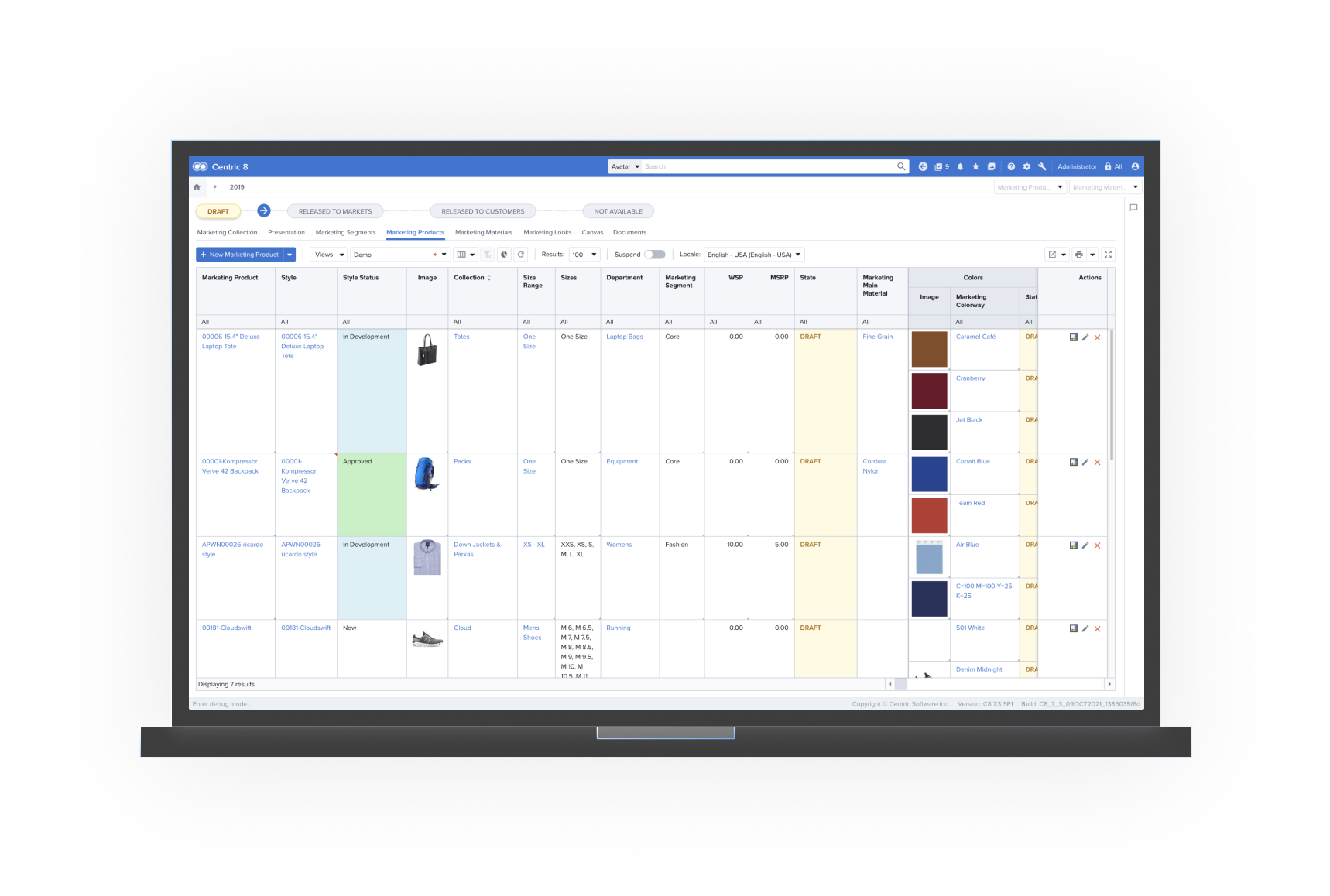

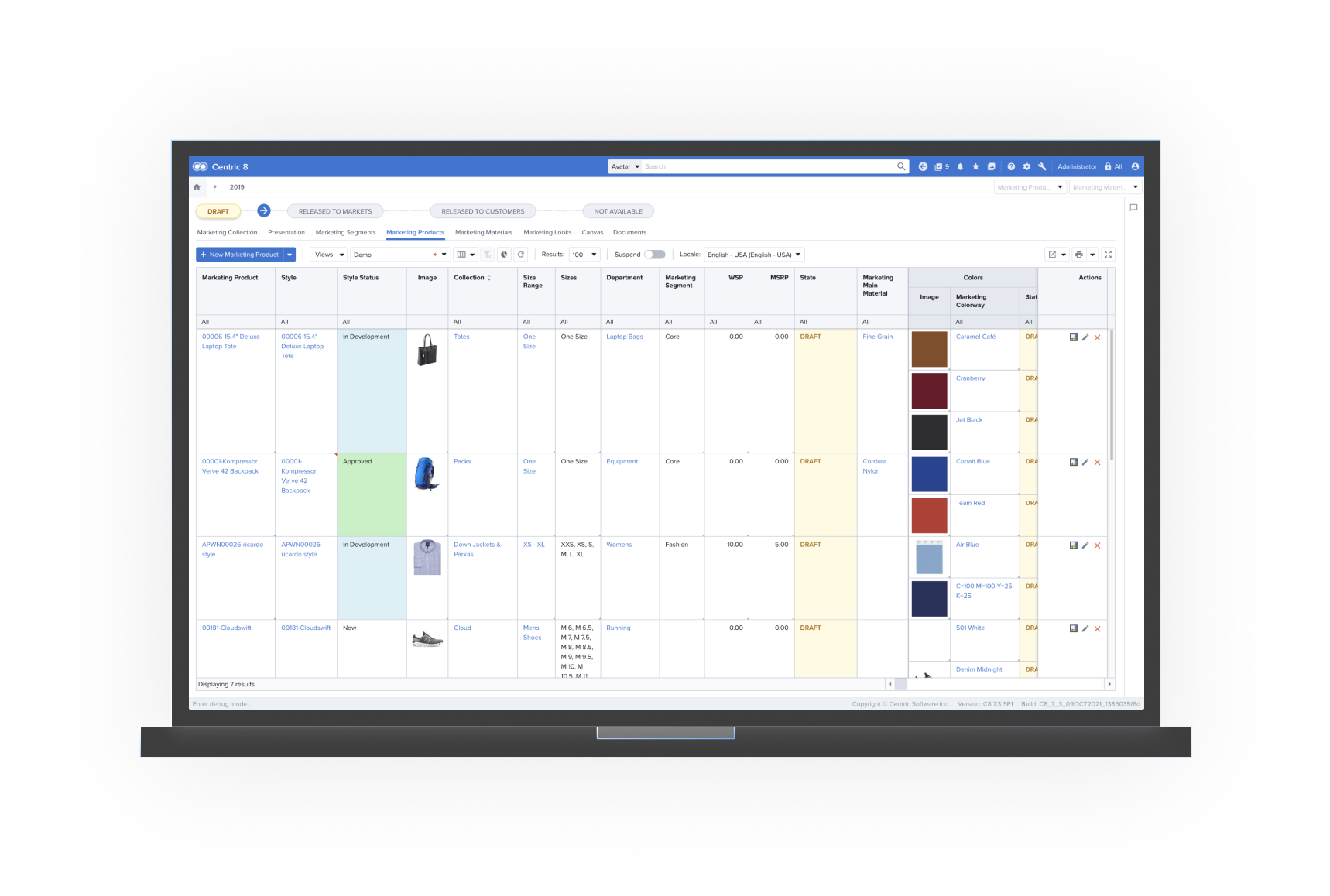

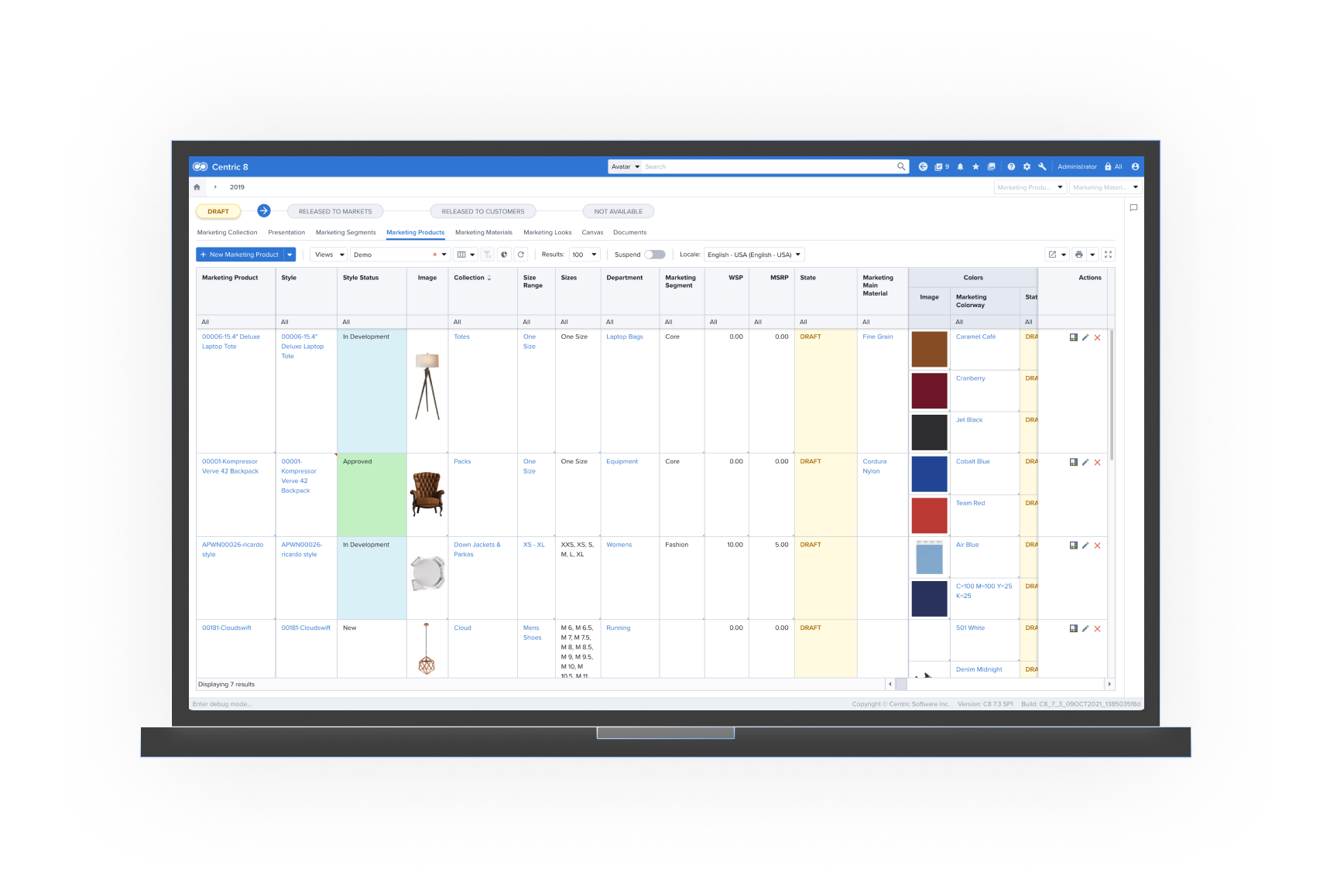

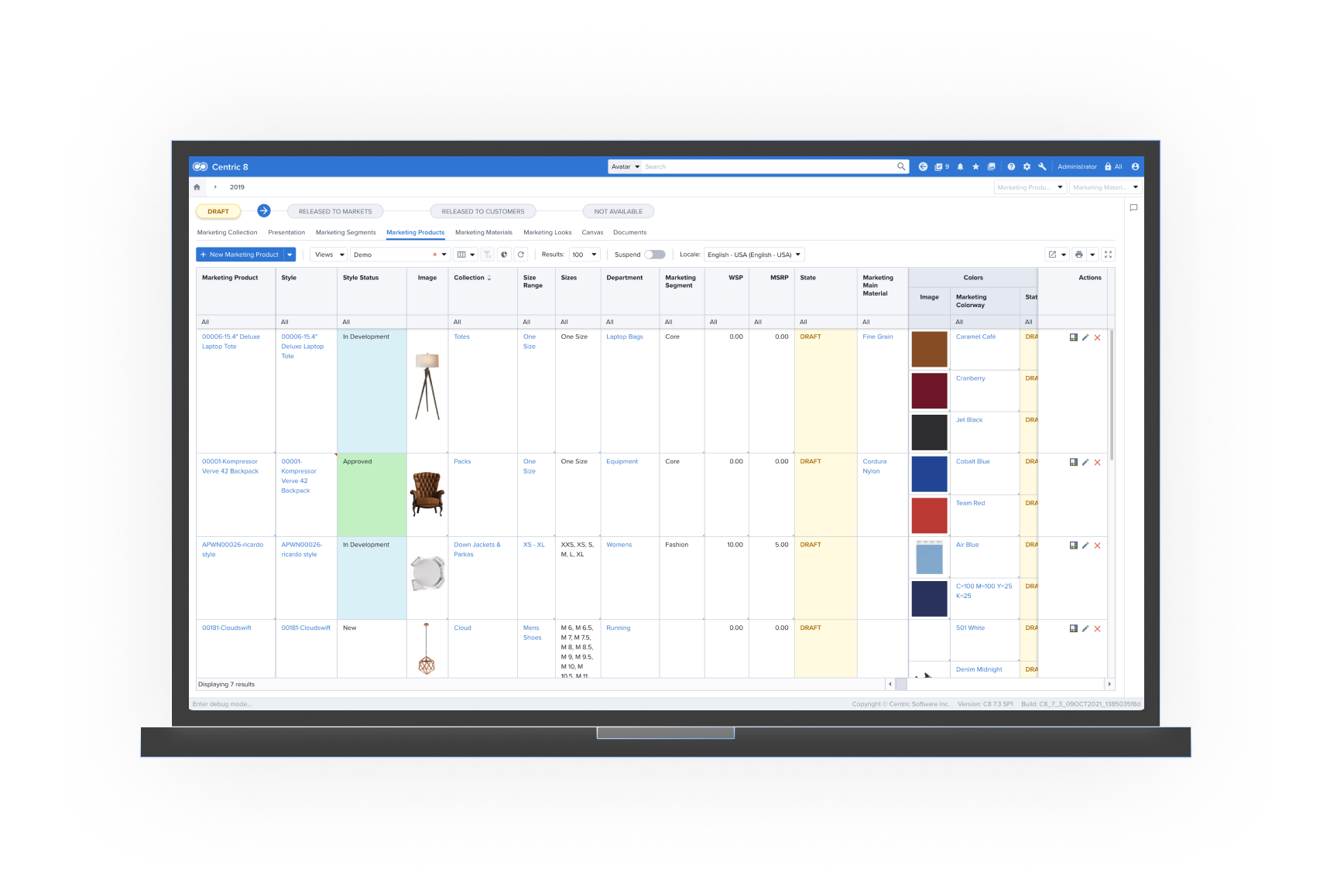

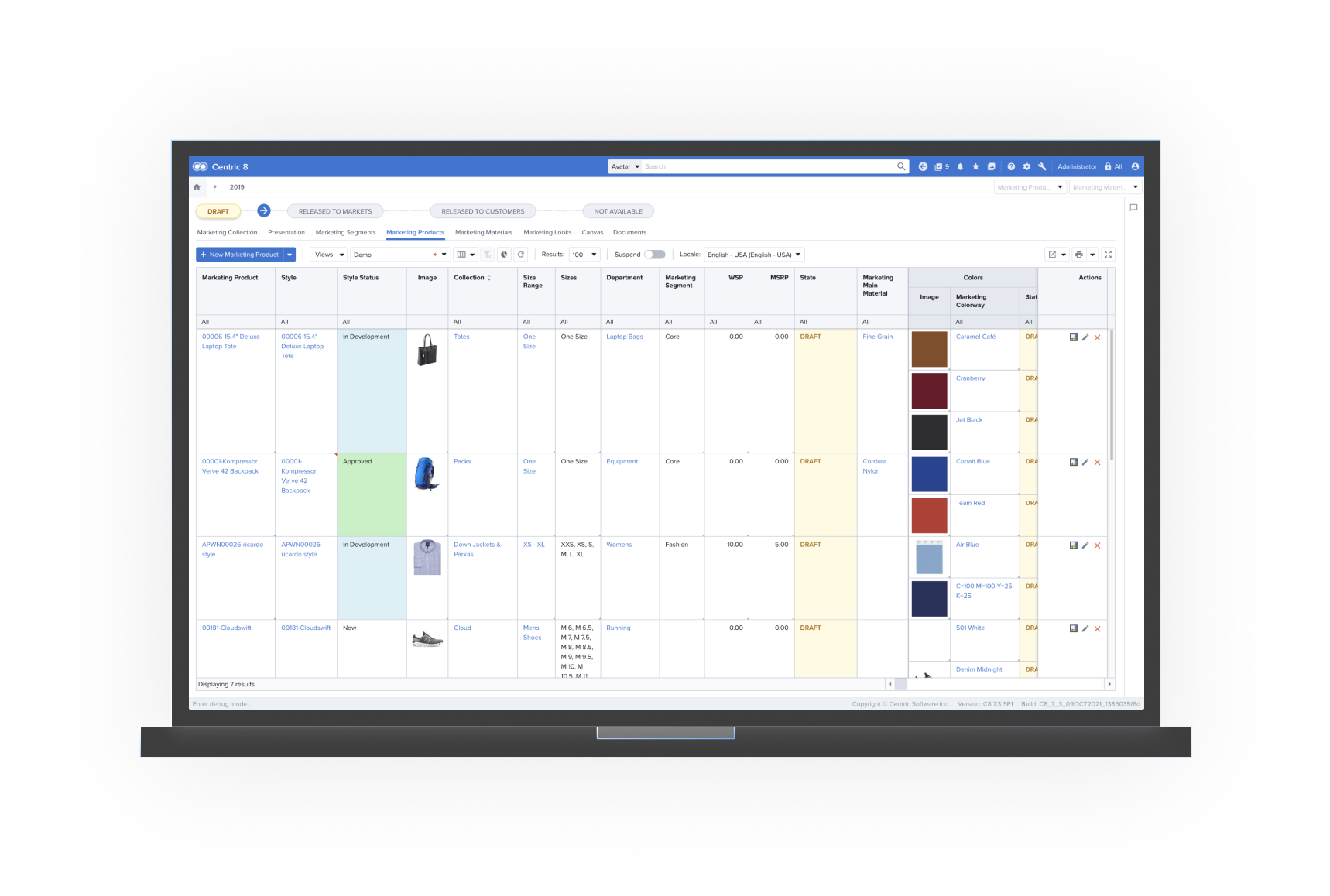

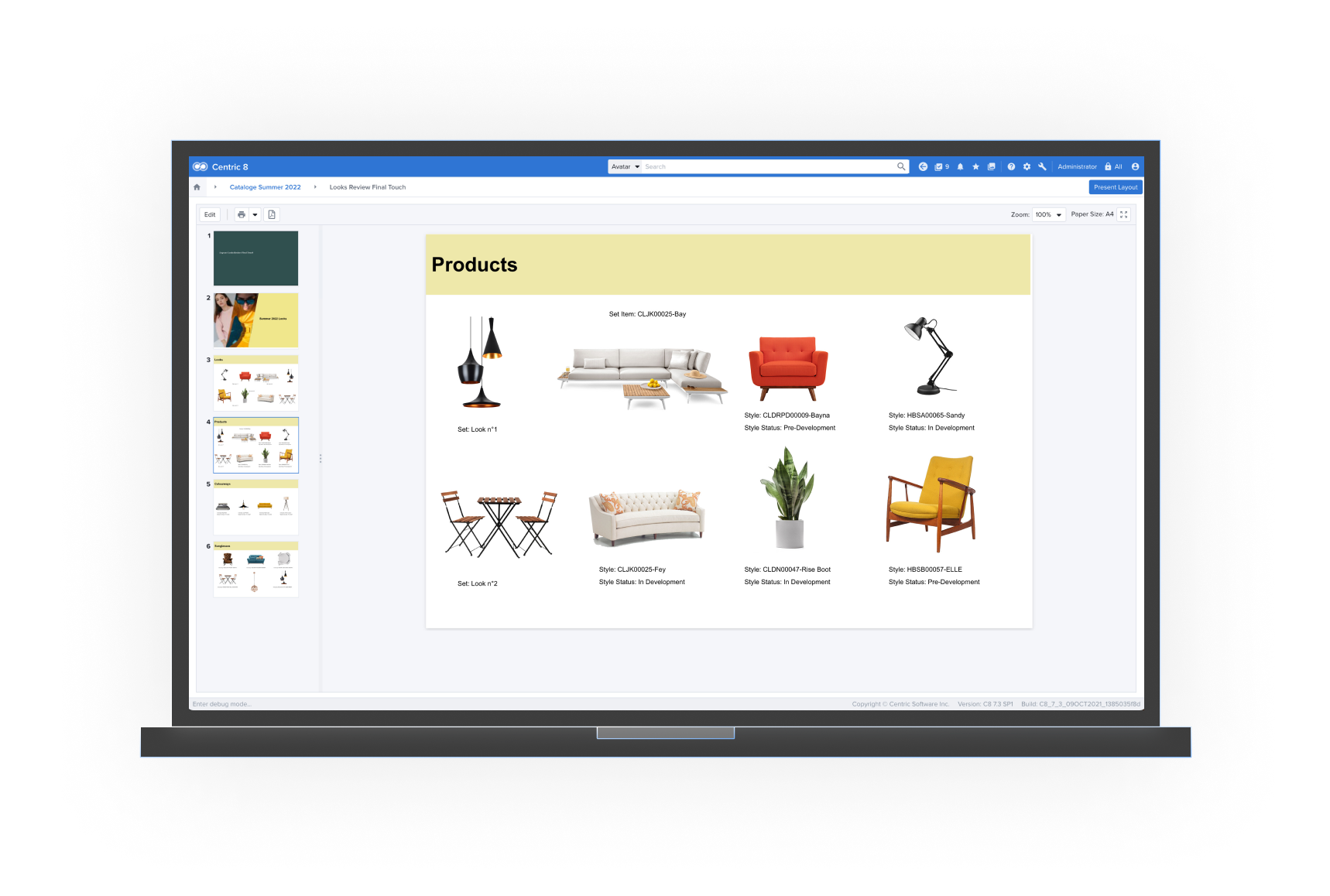

Product Presentations

Save time by creating visual product presentations directly in Centric PLM, pulling real-time data to ensure accuracy.

Filter products, visually organize them into sets, stay on-brand by using corporate fonts and leverage Centric PLM’s Canvas tool to build presentations that drive decision-making. Eliminate the tedious process of exporting visuals from PLM and save time by automatically updating presentations as product data changes.

Visual Assortment Board for PLM

Create superior assortments that optimize performance at retail with the ability to visually interact with live assortment plans.

The Visual Assortment Board for PLM merges thousands of live data points with image libraries to enable real-time team collaboration on what-if scenarios and stop/go assortment decisions.

Curate assortments that meet business objectives faster and with less waste, save valuable human resources, accelerate cycle time and deliver products consumers want to drive profitability across all channels.

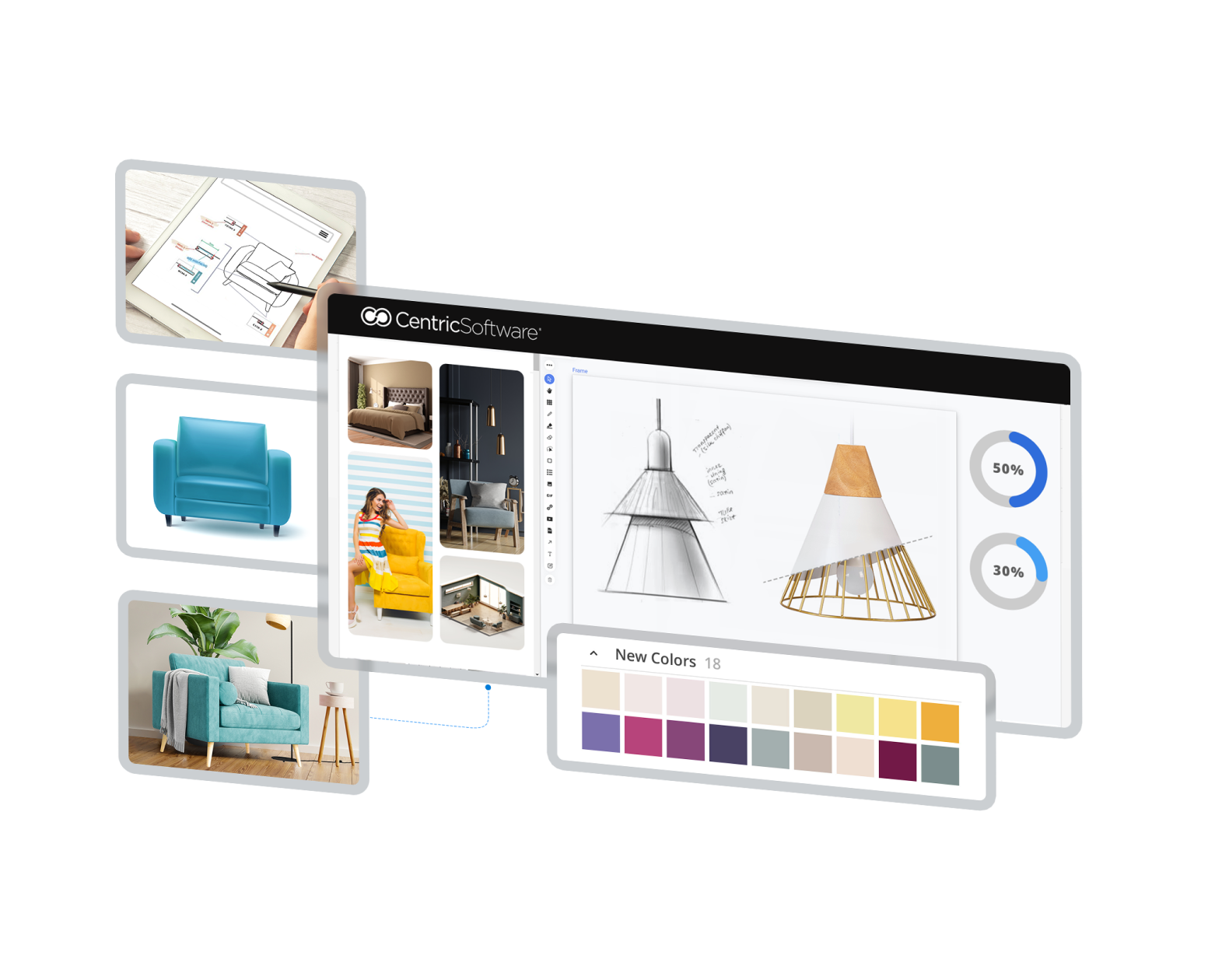

Visual Concept Board

Supercharge product innovation by reducing manual and time-consuming tasks and empowering creative collaboration.

The Concept Board is a visually interactive, intuitive digital workspace that enables creative and product development teams to collaborate around inspirations and trends using sketches, photos, videos, 3D images and more.

Reduce or eliminate manual design board creation to free up valuable time and deliver products in a flow that enhances brand performance, consumer retention and profitability.

Visual Sourcing Board

Source more cost-effectively with the ability to compare ‘what-if’ scenarios in a visually interactive workspace.

The Sourcing Board replaces siloed tools and disconnected information, empowering sourcing teams to pull together live data and visuals from multiple platforms and files to visually compare and analyze sourcing options.

Achieve projected lead times with targeted sourcing and the ability to rapidly identify alternatives, source more sustainably and meet vendor capacity targets and production deadlines while controlling costs.

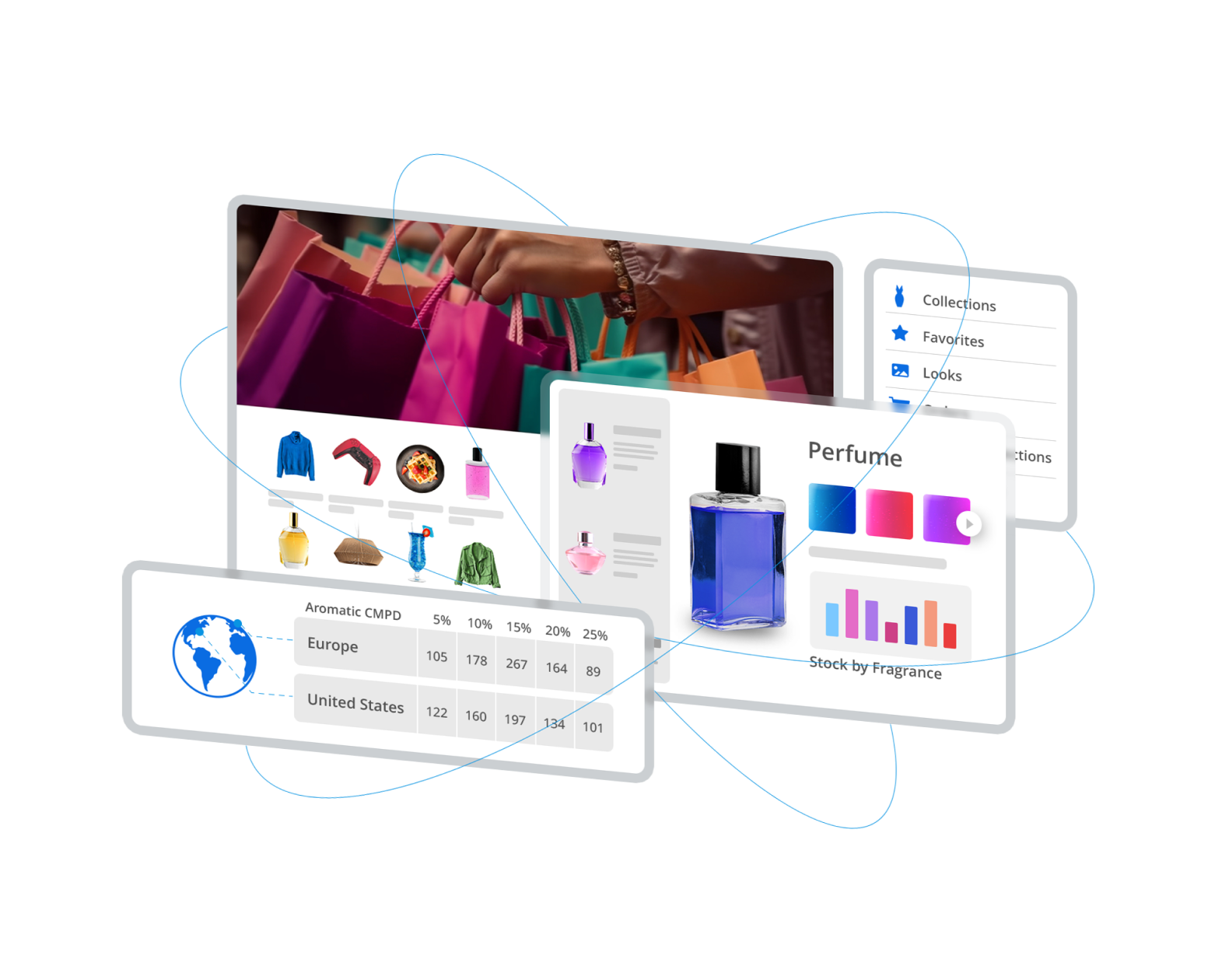

Visual Omnichannel Showroom Board

Maximize omnichannel sales opportunities with a fully digital showroom and catalog experience to reach more clients with less resources at less cost.

The Omnichannel Showroom Board enables faster, more accurate orders with a live visual interactive digital showroom. Build tailored client-centered offers using real-time product, financial and visual data, including 3D, on a single intuitive platform.

Speed time to order commitment among remote teams, eliminate unreliable paper trails and capture 100% of orders and changes digitally and in real-time. Mitigate sales risks, pivot quickly on top performers, drive targeted products across channels and forecast raw material demands accurately for earlier vendor commitment.

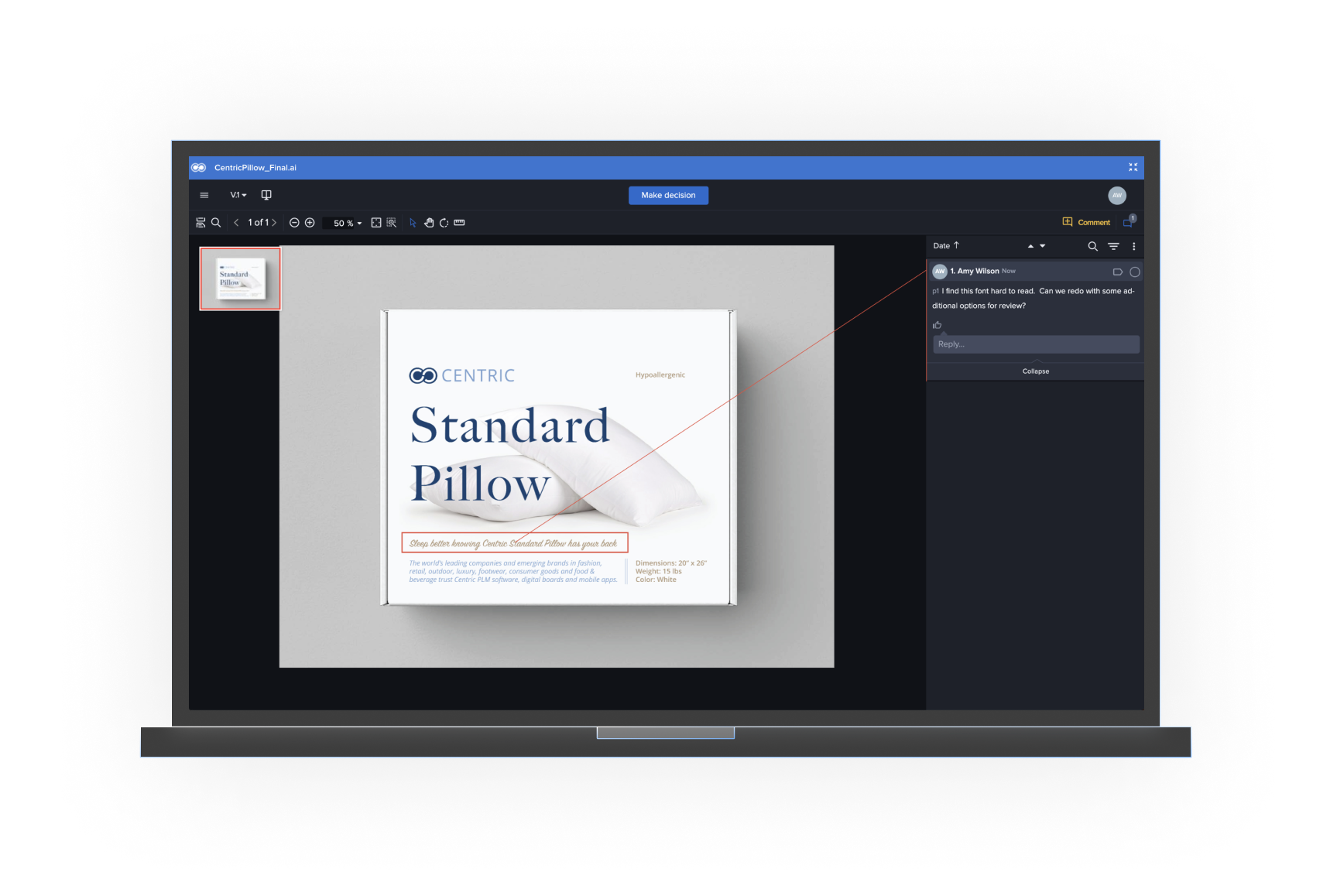

Proofing

Easily manage the artwork proofing process with an intuitive, collaborative proofing and reviewing tool.

Proofs are used to collaborate on the content, color and design elements prior to committing the artwork to copy plates and press. Users can create a proof of any document in PLM, define workflows, manage secure access, enable markup and comment threads and approval stage gates to ensure nothing gets missed.

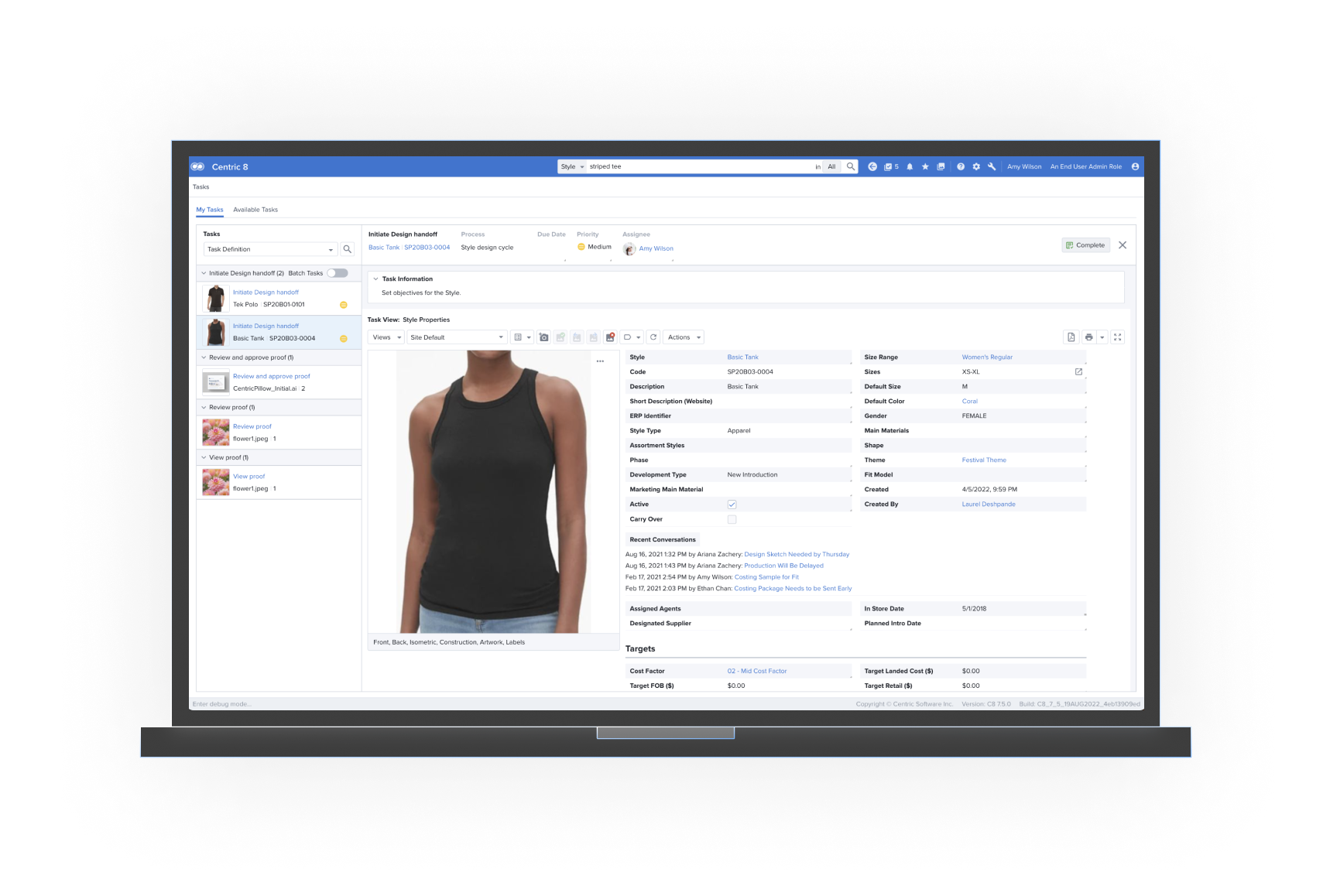

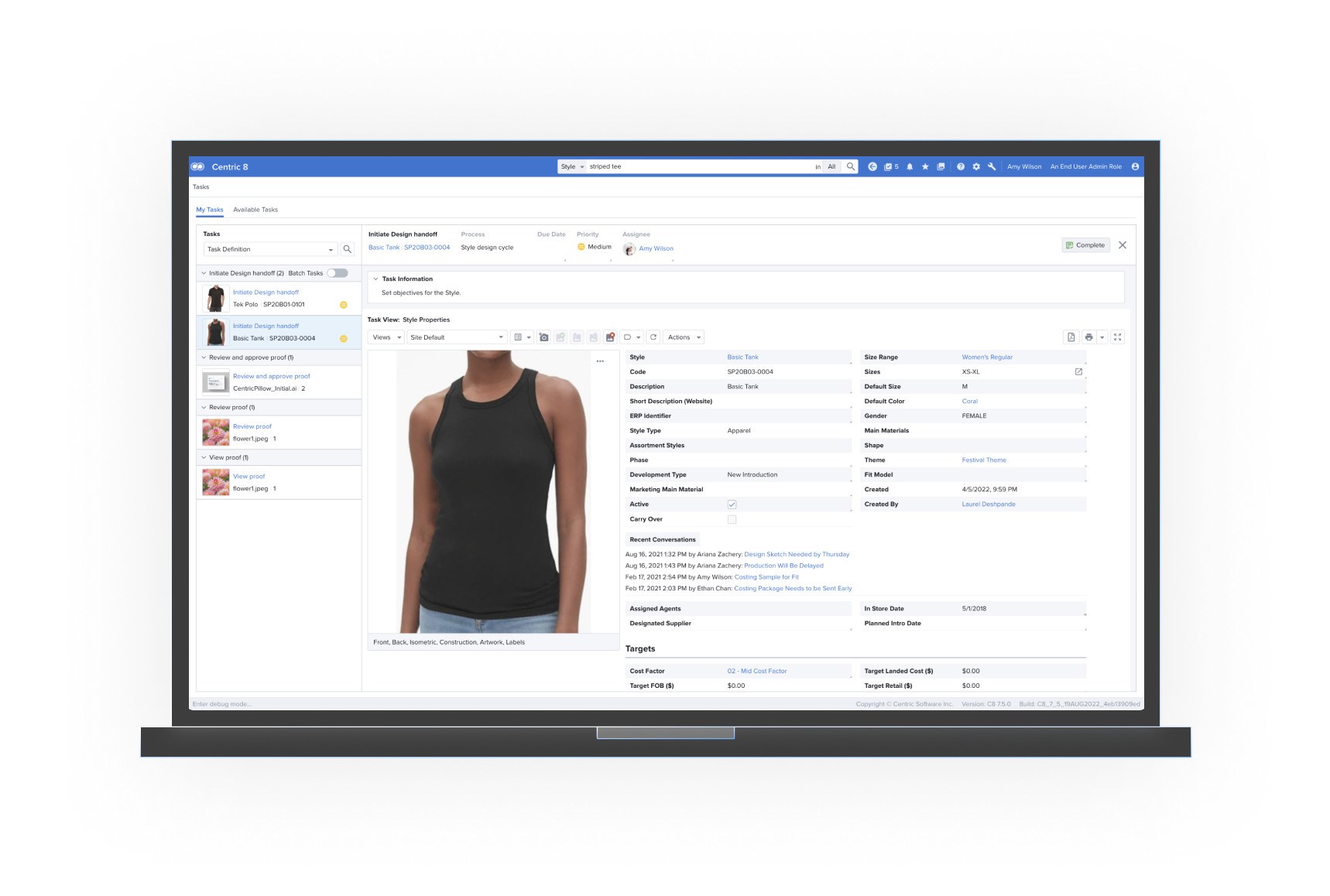

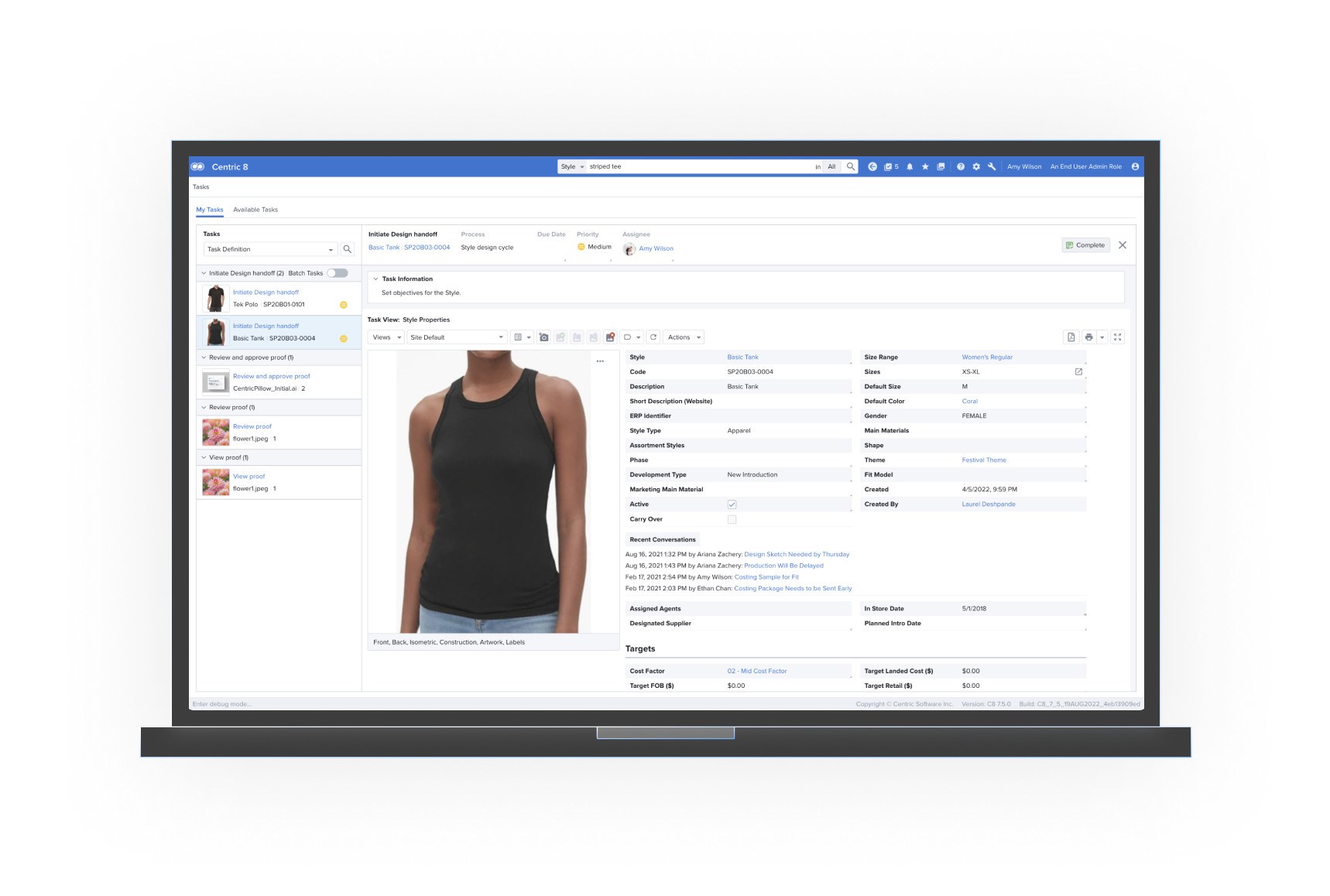

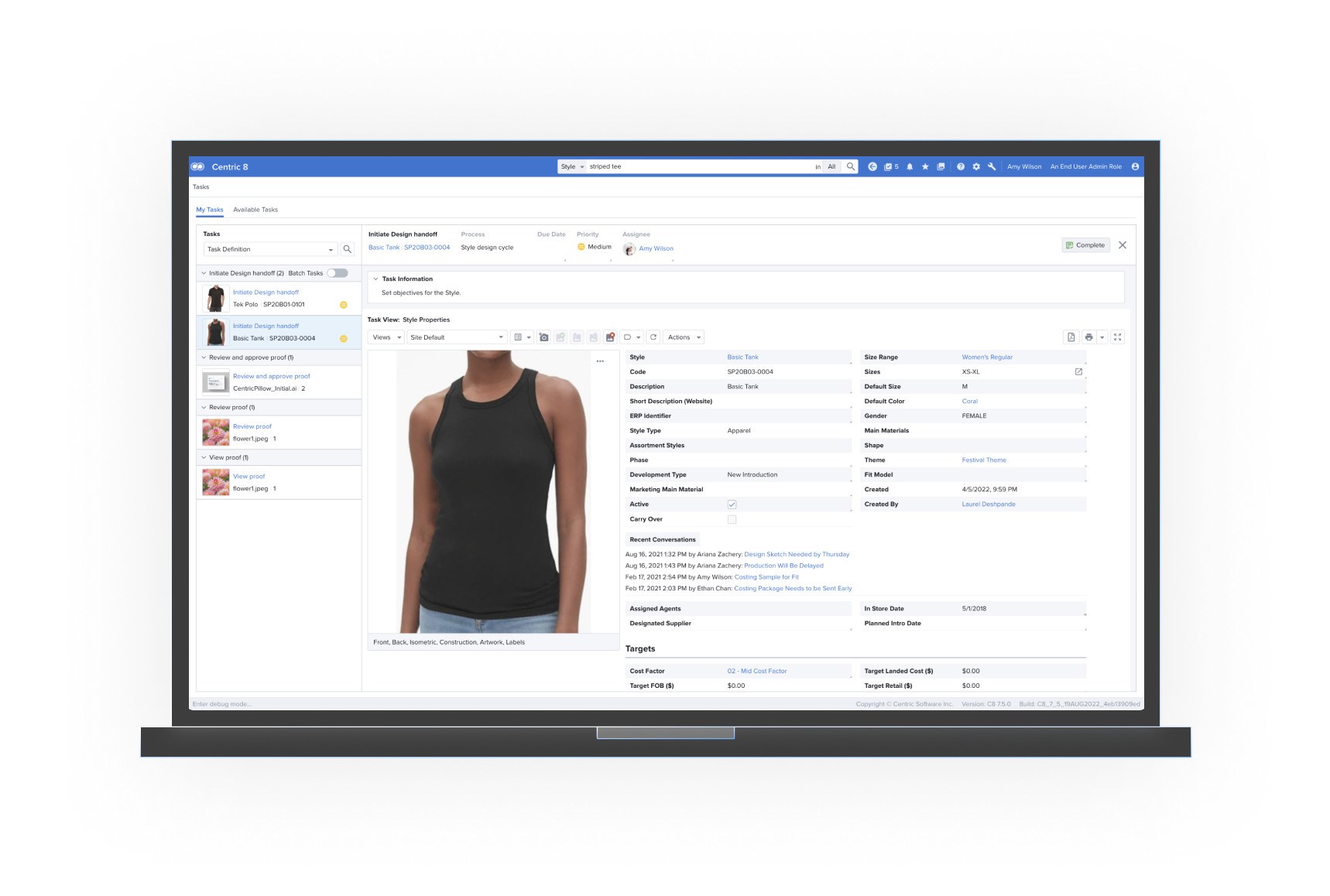

Process Management

Coordinate tasks between people by providing the ability to execute predefined processes in PLM.

A process flow is the repeatable pattern of activities or steps that take place to complete a specific task on a regular basis. Execute process flows against PLM objects to coordinate teams that need to complete tasks, improving efficiency, responsiveness, transparency and productivity.

Line Planning

Orchestrate seasons, departments, collections and product lines to meet performance targets.

Flexible analytics use always up-to-date product information to aid in the creation of top-down goals and bottom-up estimates. Fully align collection development with financial planning, generate realistic sales forecasts, easily identify outliers that impact performance, and make decisions with confidence based on data, not “guesstimates.”

Product Specifications

Easy-to-use interface to create and manage multiple product, raw material and packaging specifications.

Communicate specifications effectively to minimize iterations, errors and costs. Track product lifecycle changes and coordinate with all development teams so that designers, technical designers and/or product developers can do their jobs easily and efficiently.

Materials Management

Empower traceability with the ability to track material usage and view the entire lifecycle of a material prior to use in a product.

Manage the process of developing and using simple and complex materials. Analyze trends and manage changes by rolling up information from style to material for reporting, or initiating changes from materials to multiple styles.

Product Sourcing

Connect sourcing teams and suppliers with Centric PLM, streamline communication and access vendor information.

Handle all aspects of sourcing, from selecting suppliers to managing samples and prototypes to negotiating purchase orders. Manage supplier sustainability certifications, track supplier-quoted costs, send RFQs en masse and easily compare quotes.

Calendar Management

Gain full visibility of timelines and manage tasks, deadlines and workflow across teams.

Configure templates to track products against target deadlines and give users visibility into where a product is in its lifecycle as activities are completed, keeping teams on track and enabling greater transparency, collaboration and planning.

Quality Management

Assign quality and safety goals based on both corporate standards as well as channel-specific standards.

Define quality assurance, performance and mechanical tests on products to eliminate quality issues. Specify third party testing standards and track testing completed on materials and samples/styles to enhance quality, brand reputation and consumer loyalty.

Final Inspection

Expand the power of PLM into production with complete, real-time transparency into both vendor performance and production output.

Final Inspection enables brands and retailers to set acceptable quality levels and evaluation points for suppliers on a per product basis, linked to original product specifications. Evaluation criteria and results are communicated digitally prior to goods leaving the manufacturing site and transfer of ownership.

Proofing

Easily manage the artwork proofing process with an intuitive, collaborative proofing and reviewing tool.

Proofs are used to collaborate on the content, color and design elements prior to committing the artwork to copy plates and press. Users can create a proof of any document in PLM, define workflows, manage secure access, enable markup and comment threads and approval stage gates to ensure nothing gets missed.

Process Management

Coordinate tasks between people by providing the ability to execute predefined processes in PLM.

A process flow is the repeatable pattern of activities or steps that take place to complete a specific task on a regular basis. Execute process flows against PLM objects to coordinate teams that need to complete tasks, improving efficiency, responsiveness, transparency and productivity.

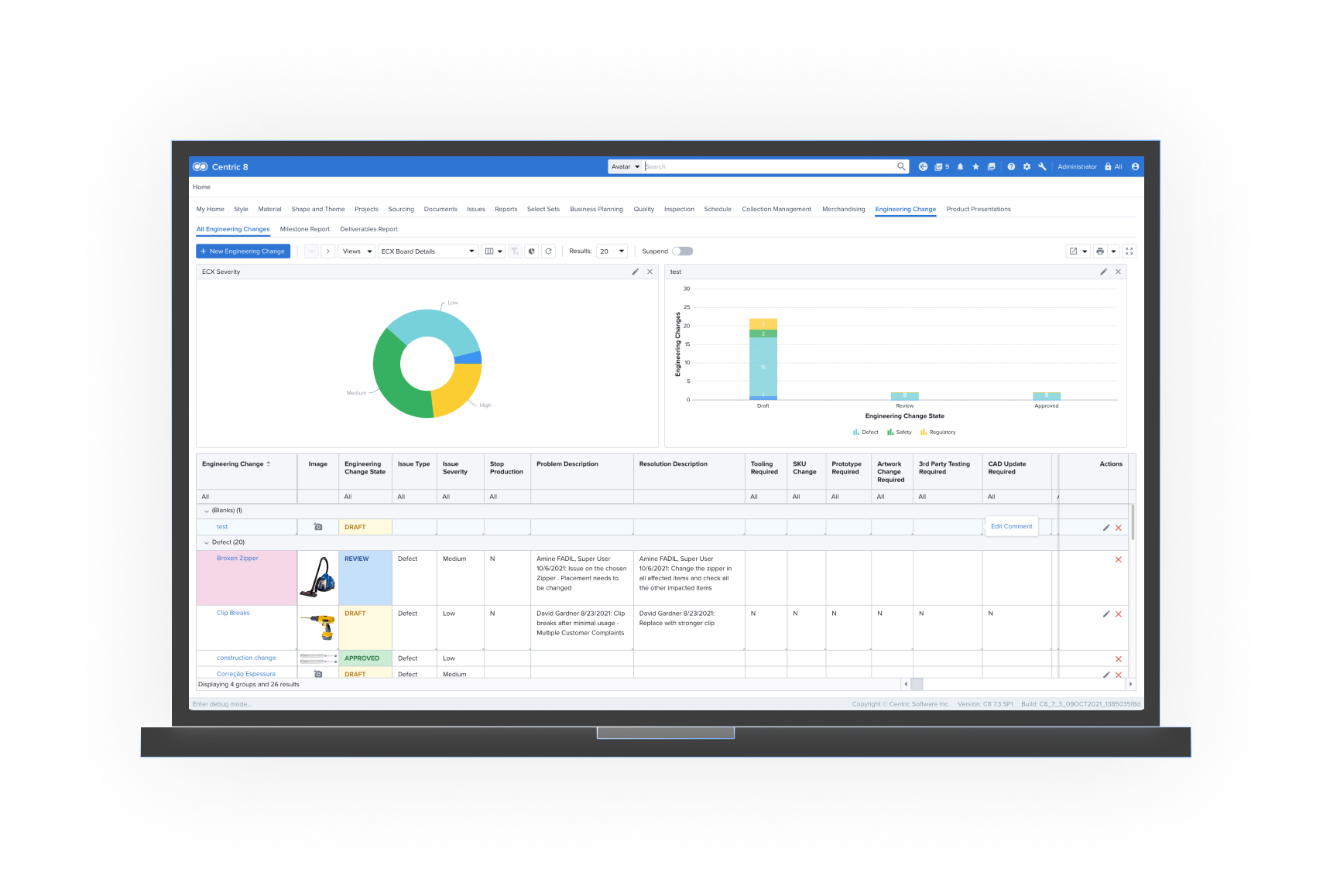

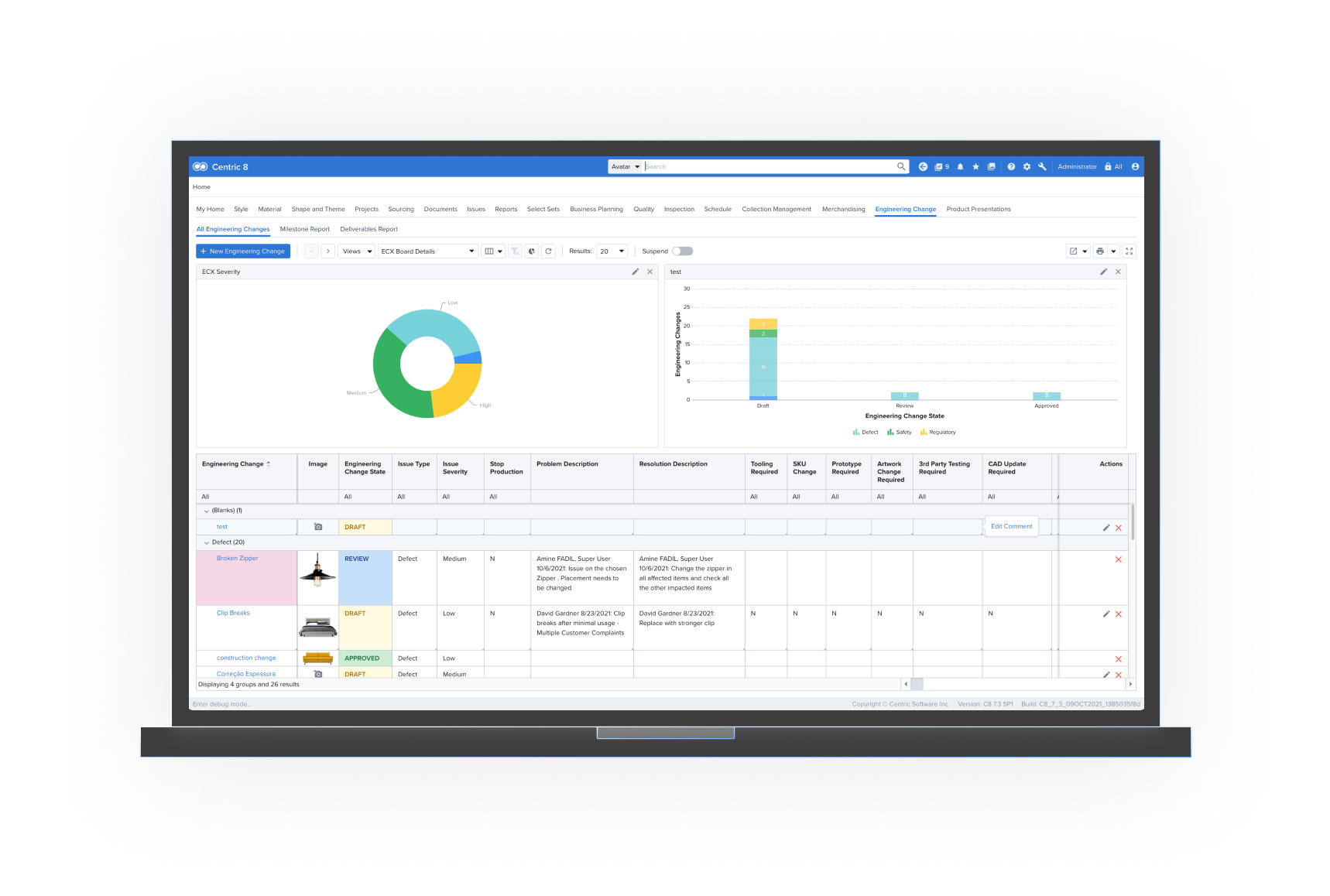

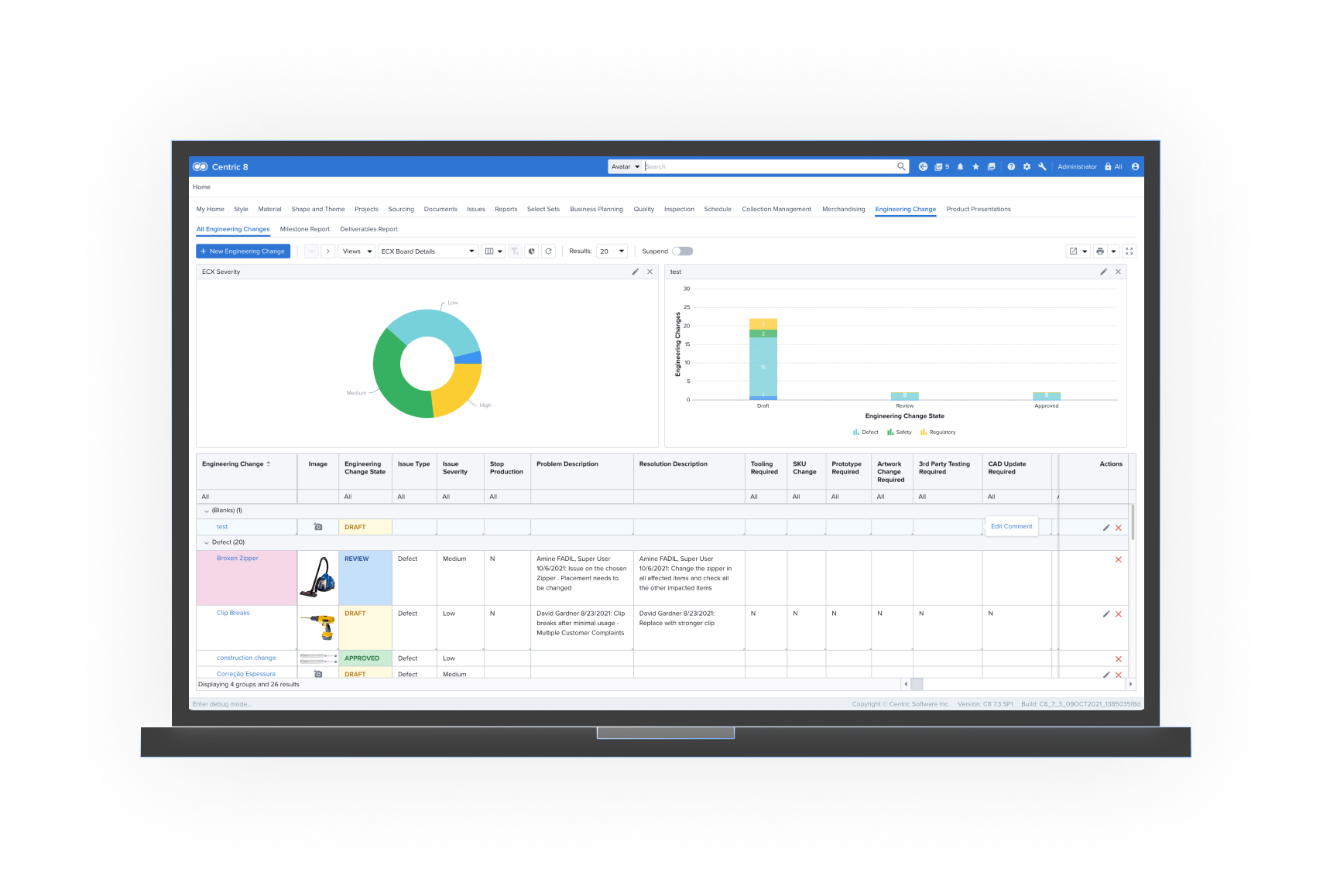

Engineering Change

Manage changes after production begins with the ability to quickly update non-conforming engineered products.

Since engineered products and their related materials are more structured, a simple change can impact multiple styles and materials. Create change requests, systematically identify affected products, easily manage changes and ensure proper approval steps are taken to update products.

Visual Assortment Board for PLM

Create superior assortments that optimize performance at retail with the ability to visually interact with live assortment plans.

The Visual Assortment Board for PLM merges thousands of live data points with image libraries to enable real-time team collaboration on what-if scenarios and stop/go assortment decisions.

Curate assortments that meet business objectives faster and with less waste, save valuable human resources, accelerate cycle time and deliver products consumers want to drive profitability across all channels.

Visual Concept Board

Supercharge product innovation by reducing manual and time-consuming tasks and empowering creative collaboration.

The Concept Board is a visually interactive, intuitive digital workspace that enables creative and product development teams to collaborate around inspirations and trends using sketches, photos, videos, 3D images and more.

Reduce or eliminate manual design board creation to free up valuable time and deliver products in a flow that enhances brand performance, consumer retention and profitability.

Visual Sourcing Board

Source more cost-effectively with the ability to compare ‘what-if’ scenarios in a visually interactive workspace.

The Sourcing Board replaces siloed tools and disconnected information, empowering sourcing teams to pull together live data and visuals from multiple platforms and files to visually compare and analyze sourcing options.

Achieve projected lead times with targeted sourcing and the ability to rapidly identify alternatives, source more sustainably and meet vendor capacity targets and production deadlines while controlling costs.

Visual Omnichannel Showroom Board

Maximize omnichannel sales opportunities with a fully digital showroom and catalog experience to reach more clients with less resources at less cost.

The Omnichannel Showroom Board enables faster, more accurate orders with a live visual interactive digital showroom. Build tailored client-centered offers using real-time product, financial and visual data, including 3D, on a single intuitive platform.

Speed time to order commitment among remote teams, eliminate unreliable paper trails and capture 100% of orders and changes digitally and in real-time. Mitigate sales risks, pivot quickly on top performers, drive targeted products across channels and forecast raw material demands accurately for earlier vendor commitment.

Retail Review

Maintain consistent branding, merchandising, promotions and policies across multiple stores with fast, mobile and effective digital store assessment technology.

Retail Review can be used on mobile devices by store assessors to enter feedback onsite in real time, adding media such as photos, videos or voice recordings. Save time spent entering data back at your desk and get instant reports and corrective plans online in Centric PLM to drive brand consistency and deliver the same quality of experience across all stores.

Line Planning

Orchestrate seasons, departments, collections and product lines to meet performance targets.

Flexible analytics use always up-to-date product information to aid in the creation of top-down goals and bottom-up estimates. Fully align collection development with financial planning, generate realistic sales forecasts, easily identify outliers that impact performance, and make decisions with confidence based on data, not “guesstimates.”

Product Specifications

Easy-to-use interface to create and manage multiple product, raw material and packaging specifications.

Communicate specifications effectively to minimize iterations, errors and costs. Track product lifecycle changes and coordinate with all development teams so that designers, technical designers and/or product developers can do their jobs easily and efficiently.

Materials Management

Empower traceability with the ability to track material usage and view the entire lifecycle of a material prior to use in a product.

Manage the process of developing and using simple and complex materials. Analyze trends and manage changes by rolling up information from style to material for reporting, or initiating changes from materials to multiple styles.

Product Sourcing

Connect sourcing teams and suppliers with Centric PLM, streamline communication and access vendor information.

Handle all aspects of sourcing, from selecting suppliers to managing samples and prototypes to negotiating purchase orders. Manage supplier sustainability certifications, track supplier-quoted costs, send RFQs en masse and easily compare quotes.

Calendar Management

Gain full visibility of timelines and manage tasks, deadlines and workflow across teams.

Configure templates to track products against target deadlines and give users visibility into where a product is in its lifecycle as activities are completed, keeping teams on track and enabling greater transparency, collaboration and planning.

Quality Management

Assign quality and safety goals based on both corporate standards as well as channel-specific standards.

Define quality assurance, performance and mechanical tests on products to eliminate quality issues. Specify third party testing standards and track testing completed on materials and samples/styles to enhance quality, brand reputation and consumer loyalty.

Final Inspection

Expand the power of PLM into production with complete, real-time transparency into both vendor performance and production output.

Final Inspection enables brands and retailers to set acceptable quality levels and evaluation points for suppliers on a per product basis, linked to original product specifications. Evaluation criteria and results are communicated digitally prior to goods leaving the manufacturing site and transfer of ownership.

Proofing

Easily manage the artwork proofing process with an intuitive, collaborative proofing and reviewing tool.

Proofs are used to collaborate on the content, color and design elements prior to committing the artwork to copy plates and press. Users can create a proof of any document in PLM, define workflows, manage secure access, enable markup and comment threads and approval stage gates to ensure nothing gets missed.

Process Management

Coordinate tasks between people by providing the ability to execute predefined processes in PLM.

A process flow is the repeatable pattern of activities or steps that take place to complete a specific task on a regular basis. Execute process flows against PLM objects to coordinate teams that need to complete tasks, improving efficiency, responsiveness, transparency and productivity.

Engineering Change

Manage changes after production begins with the ability to quickly update non-conforming engineered products.

Since engineered products and their related materials are more structured, a simple change can impact multiple styles and materials. Create change requests, systematically identify affected products, easily manage changes and ensure proper approval steps are taken to update products.

Product Presentations

Save time by creating visual product presentations directly in Centric PLM, pulling real-time data to ensure accuracy.

Filter products, visually organize them into sets, stay on-brand by using corporate fonts and leverage Centric PLM’s Canvas tool to build presentations that drive decision-making. Eliminate the tedious process of exporting visuals from PLM and save time by automatically updating presentations as product data changes.

Visual Assortment Board for PLM

Create superior assortments that optimize performance at retail with the ability to visually interact with live assortment plans.

The Visual Assortment Board for PLM merges thousands of live data points with image libraries to enable real-time team collaboration on what-if scenarios and stop/go assortment decisions.

Curate assortments that meet business objectives faster and with less waste, save valuable human resources, accelerate cycle time and deliver products consumers want to drive profitability across all channels.

Visual Concept Board

Supercharge product innovation by reducing manual and time-consuming tasks and empowering creative collaboration.

The Concept Board is a visually interactive, intuitive digital workspace that enables creative and product development teams to collaborate around inspirations and trends using sketches, photos, videos, 3D images and more.

Reduce or eliminate manual design board creation to free up valuable time and deliver products in a flow that enhances brand performance, consumer retention and profitability.

Visual Sourcing Board

Source more cost-effectively with the ability to compare ‘what-if’ scenarios in a visually interactive workspace.

The Sourcing Board replaces siloed tools and disconnected information, empowering sourcing teams to pull together live data and visuals from multiple platforms and files to visually compare and analyze sourcing options.

Achieve projected lead times with targeted sourcing and the ability to rapidly identify alternatives, source more sustainably and meet vendor capacity targets and production deadlines while controlling costs.

Visual Omnichannel Showroom Board

Maximize omnichannel sales opportunities with a fully digital showroom and catalog experience to reach more clients with less resources at less cost.

The Omnichannel Showroom Board enables faster, more accurate orders with a live visual interactive digital showroom. Build tailored client-centered offers using real-time product, financial and visual data, including 3D, on a single intuitive platform.

Speed time to order commitment among remote teams, eliminate unreliable paper trails and capture 100% of orders and changes digitally and in real-time. Mitigate sales risks, pivot quickly on top performers, drive targeted products across channels and forecast raw material demands accurately for earlier vendor commitment.

Centric PLM Base

The configurable foundation for compliant product development and data management.

Centric PLM Base is the platform that hosts the ‘plug-and-play’ modules to manage all the data and design processes associated with the life of a product, from planning/concept development, costing, sourcing and manufacturing to launch at retail. Configure and add modules as needed and connect with external suppliers and partners. Integrate people, data, processes and business systems.

Product Specifications

Easy-to-use interface to create and manage multiple product, raw material and packaging specifications.

Communicate specifications effectively to minimize iterations, errors and costs. Track product lifecycle changes and coordinate with all development teams so that designers, technical designers and/or product developers can do their jobs easily and efficiently.

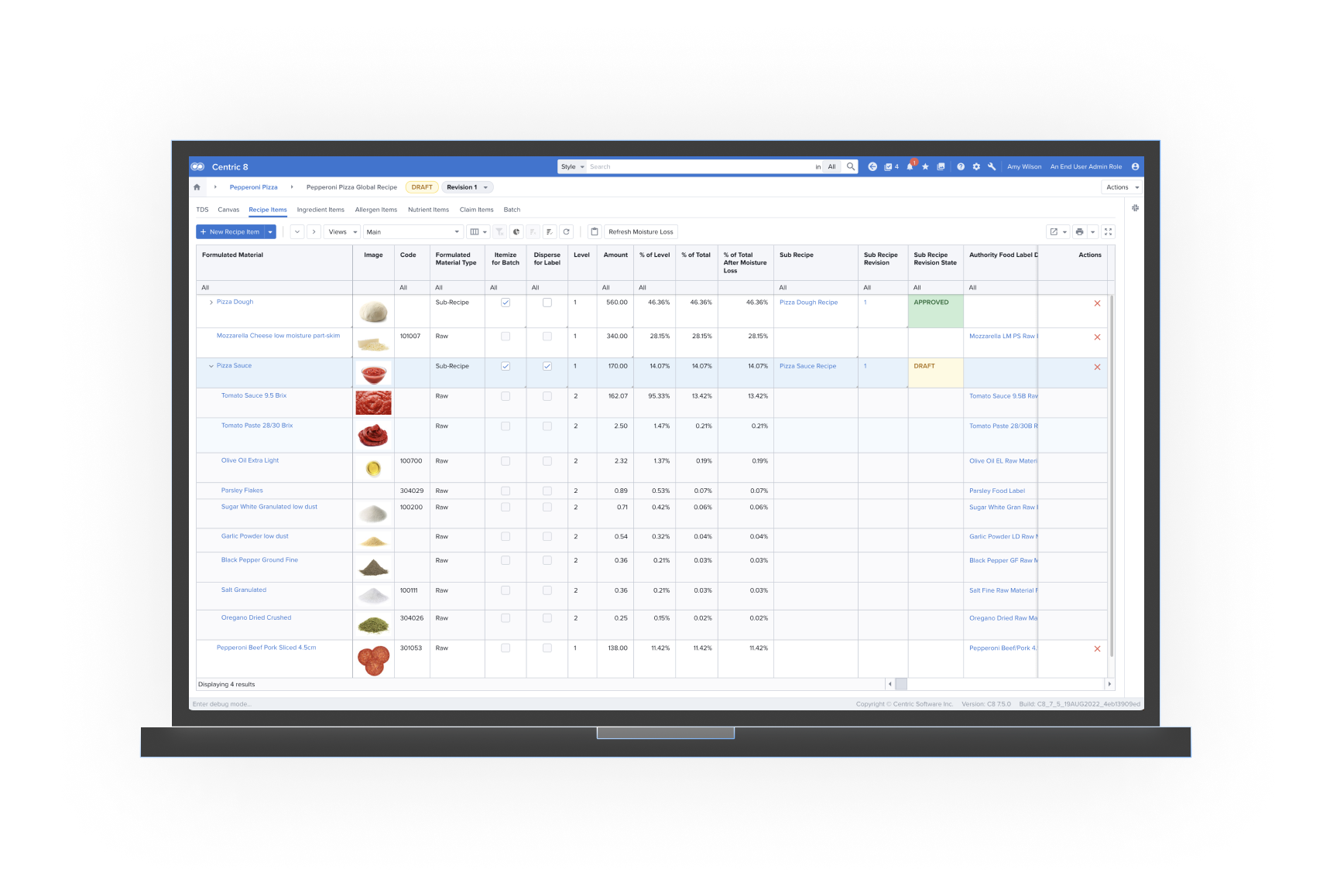

Recipe & Formulation

Streamline the development of recipes, calculate nutrition information, identify allergens and track claims.

Accelerate formulation development and reduce trial-and-error iterations to cut time to market and associated costs. Track and re-use raw material specifications and experimental formulas and understand the real-time impact of changes on cost, compliance, nutrient data and ingredient labeling to optimize formulations. Link ingredient libraries to USDA/CIQUAL for accuracy and compliance.

Product Sourcing & Costing

Effectively manage supplier co-development and speed up calls for tenders.

Maintain global visibility of your supply chain and sourcing relationships to improve supply chain performance. Issue RFQs en masse and easily compare quotes for more accurate costing. Automate supplier approvals and connect suppliers with PLM to manage document uploads, certificate renewals, data entry and artwork reviews.

Change Management

Manage complex changes to products more efficiently.

A simple change can impact multiple products and materials. Create a change request from a product, raw material, ingredient or SKU, systematically identify affected products, easily manage changes and ensure proper approval steps are taken to update products. Increase the visibility of changes and execute bulk changes in seconds.

Packaging & Artwork

Manage artwork, packaging design/development and consumer labeling.

Streamline packaging and labeling to cut time to market with collaborative design and proofing tools. Aggregate all up-to-date packaging and labeling information, from technical data on ingredients and label claims to marketing data, for use on consumer and trade packaging. Respond to consumer demand for sustainable packaging while maximizing efficiency to keep costs down. Save time and money by supporting the efficient reuse of designs.

Project Management

Create flexible projects or workflows for products, assortments or modifications and gain full visibility of timelines.

Accelerate product development and launches to reach the market faster, improve the success rate of new products and increase ROI for product development. Manage projects across functions and geographic locations via a web-enabled platform, track all activities and decisions and make portfolio-level decisions based on visibility of aggregated project metrics.

Quality & Compliance

Ensure product quality, consumer safety and regulatory compliance.

Assign quality and safety goals based on both corporate standards as well as channel-specific standards. Manage conformance to specification through testing protocols, avoid rework and recalls by building compliance screening into new product development, validate claims through the new product development process and maintain accurate raw materials data.

Portfolio & Merchandise Planning

Manage and optimize your product portfolio and assortments to meet performance targets and optimize new product development.

Align financial objectives with merchandise plans, run what-if scenarios and roll up actual financials for analysis in top-down and bottom-up planning. Quickly react to market changes to preserve or increase revenues and margins, control product costs by driving supply chain simplification and maintain data accuracy and completeness in product catalogs and presentations.

Product Presentations

Save time by creating visual product presentations directly in Centric PLM, pulling real-time data to ensure accuracy.

Filter products, visually organize them into sets, stay on-brand by using corporate fonts and leverage Centric PLM’s Canvas tool to build presentations that drive decision-making. Eliminate the tedious process of exporting visuals from PLM and save time by automatically updating presentations as product data changes.

Visual Assortment Board for PLM

Create superior assortments that optimize performance at retail with the ability to visually interact with live assortment plans.

The Visual Assortment Board for PLM merges thousands of live data points with image libraries to enable real-time team collaboration on what-if scenarios and stop/go assortment decisions.

Curate assortments that meet business objectives faster and with less waste, save valuable human resources, accelerate cycle time and deliver products consumers want to drive profitability across all channels.

Visual Concept Board

Supercharge product innovation by reducing manual and time-consuming tasks and empowering creative collaboration.

The Concept Board is a visually interactive, intuitive digital workspace that enables creative and product development teams to collaborate around inspirations and trends using sketches, photos, videos, 3D images and more.

Reduce or eliminate manual design board creation to free up valuable time and deliver products in a flow that enhances brand performance, consumer retention and profitability.

Visual Sourcing Board

Source more cost-effectively with the ability to compare ‘what-if’ scenarios in a visually interactive workspace.

The Sourcing Board replaces siloed tools and disconnected information, empowering sourcing teams to pull together live data and visuals from multiple platforms and files to visually compare and analyze sourcing options.

Achieve projected lead times with targeted sourcing and the ability to rapidly identify alternatives, source more sustainably and meet vendor capacity targets and production deadlines while controlling costs.

Visual Omnichannel Showroom Board

Maximize omnichannel sales opportunities with a fully digital showroom and catalog experience to reach more clients with less resources at less cost.

The Omnichannel Showroom Board enables faster, more accurate orders with a live visual interactive digital showroom. Build tailored client-centered offers using real-time product, financial and visual data, including 3D, on a single intuitive platform.

Speed time to order commitment among remote teams, eliminate unreliable paper trails and capture 100% of orders and changes digitally and in real-time. Mitigate sales risks, pivot quickly on top performers, drive targeted products across channels and forecast raw material demands accurately for earlier vendor commitment.

Merchandise Planning

Manage all global categories and product lines to meet performance targets.

Flexible analytics use always up-to-date product data to aid in the creation of top-down goals and bottom-up estimates. Fully align collection development with financial planning, generate realistic sales forecasts, easily identify outliers that impact performance, and make decisions with confidence based on data, not “guesstimates.”

Product Specification & Proofing

Easy-to-use interface to manage product, material, component and packaging specifications and proofing.

Communicate specifications effectively to minimize iterations, errors and costs. Track product lifecycle changes and coordinate teams so that designers, technical designers and/or product developers can work easily and efficiently. Manage the artwork proofing process with an intuitive, collaborative proofing and reviewing tool.

Component and Material Management

Empower traceability with the ability to track component usage and view the entire lifecycle of a material prior to use in a product.

Manage the process of developing and using simple and complex components. Analyze usage and manage changes by rolling up information from product to component for reporting, or initiate changes from components to multiple items.

Product Sourcing

Connect sourcing teams and suppliers with Centric PLM, streamline communication and access vendor information.

Orchestrate sourcing, from selecting suppliers to managing samples and prototypes to negotiating purchase orders. Manage supplier sustainability certifications, track supplier-quoted costs, send RFQs en masse and easily compare quotes.

Engineering Change Control

Manage changes after production begins with the ability to quickly update non-conforming engineered products.

Since engineered products and their related materials are more structured, a simple change can impact multiple styles and materials. Create change requests, systematically identify affected products, easily manage changes and ensure proper approval steps are taken to update products.

Calendar Management

Gain full visibility of timelines and manage tasks, deadlines and workflow across teams.

Configure templates to track products against target deadlines and give users visibility into where a product is in its lifecycle as activities are completed, keeping teams on track and enabling greater transparency, collaboration and planning.

QMS & Compliance

Record compliance at every stage of product development and ensure quality standards with a built-in Quality Management Solution (QMS).

Maintain full visibility and decision stage gate history attached directly to product records. Assign quality and safety goals based on both corporate standards as well as channel-specific standards. Manage conformance to specification through testing protocols and avoid rework and recalls by building compliance screening into new product development.

Process Management

Coordinate tasks between people by providing the ability to execute predefined processes in PLM.

A process flow is the repeatable pattern of activities or steps that take place to complete a specific task on a regular basis. Execute process flows against PLM objects to coordinate teams that need to complete tasks, improving efficiency, responsiveness, transparency and productivity.

Visual Assortment Board for PLM

Create superior assortments that optimize performance at retail with the ability to visually interact with live assortment plans.

The Visual Assortment Board for PLM merges thousands of live data points with image libraries to enable real-time team collaboration on what-if scenarios and stop/go assortment decisions.

Curate assortments that meet business objectives faster and with less waste, save valuable human resources, accelerate cycle time and deliver products consumers want to drive profitability across all channels.

Visual Concept Board

Supercharge product innovation by reducing manual and time-consuming tasks and empowering creative collaboration.

The Concept Board is a visually interactive, intuitive digital workspace that enables creative and product development teams to collaborate around inspirations and trends using sketches, photos, videos, 3D images and more.

Reduce or eliminate manual design board creation to free up valuable time and deliver products in a flow that enhances brand performance, consumer retention and profitability.

Visual Sourcing Board

Source more cost-effectively with the ability to compare ‘what-if’ scenarios in a visually interactive workspace.

The Sourcing Board replaces siloed tools and disconnected information, empowering sourcing teams to pull together live data and visuals from multiple platforms and files to visually compare and analyze sourcing options.

Achieve projected lead times with targeted sourcing and the ability to rapidly identify alternatives, source more sustainably and meet vendor capacity targets and production deadlines while controlling costs.

Visual Omnichannel Showroom Board

Maximize omnichannel sales opportunities with a fully digital showroom and catalog experience to reach more clients with less resources at less cost.

The Omnichannel Showroom Board enables faster, more accurate orders with a live visual interactive digital showroom. Build tailored client-centered offers using real-time product, financial and visual data, including 3D, on a single intuitive platform.

Speed time to order commitment among remote teams, eliminate unreliable paper trails and capture 100% of orders and changes digitally and in real-time. Mitigate sales risks, pivot quickly on top performers, drive targeted products across channels and forecast raw material demands accurately for earlier vendor commitment.

Centric PLM Base

The configurable foundation for compliant product development and data management.

Centric PLM Base is the platform that hosts the ‘plug-and-play’ modules to manage all the data and design processes associated with the life of a product, from planning/concept development, costing, sourcing and manufacturing to launch at retail. Configure and add modules as needed and connect with external suppliers and partners. Integrate people, data, processes and business systems.

Product Specifications

Easy-to-use interface to create and manage multiple product, raw material and packaging specifications.

Communicate specifications effectively to minimize iterations, errors and costs. Track product lifecycle changes and coordinate with all development teams so that designers, technical designers and/or product developers can do their jobs easily and efficiently.

Trials & Formulation Management

Streamline the development of formulations, manage trials, optimize costs and track compliance.

Accelerate formulation development and reduce trial-and-error iterations to cut time to market and associated costs. Link with the INCI database as a library for QQ formula generation. Track and re-use raw material specifications and experimental formulas and understand the real-time impact

Product Sourcing & Costing

Effectively manage collaboration with suppliers and speed up calls for tenders.

Maintain global visibility of your supply chain and sourcing relationships to improve supply chain performance. Issue RFQs en masse and easily compare quotes for more accurate costing. Automate supplier approvals, collaborate with suppliers digitally and share policy and procedure documentation to facilitate compliance.

Change Management

Manage complex changes to products more efficiently.

A simple change can impact multiple products and materials. Create a change request from a product, raw material, ingredient or SKU, systematically identify affected products, easily manage changes and ensure proper approval steps are taken to update products. Increase the visibility of changes and execute bulk changes in seconds.

Packaging & Labeling

Manage packaging design/development, artwork proofing and consumer labeling.

Streamline packaging and labeling to cut time to market with collaborative design and proofing tools. Aggregate all up-to-date packaging and labeling information, from technical data on ingredients and label claims to marketing data, for use on consumer and trade packaging. Respond to consumer demand for sustainable packaging while maximizing efficiency to keep costs down. Save time and money by supporting the efficient reuse of designs.

Innovation & Project Management

Create flexible projects or workflows, gain full visibility of timelines and free up teams to innovate and create.

Accelerate product development and launches to reach the market faster, improve the success rate of new products and increase ROI for product development. Manage projects across functions and geographic regions, track all activities and decisions and free teams from time-consuming admin work to power creativity.

Compliance & Quality Management

Ensure product quality, consumer safety and regulatory compliance.

Assign quality and safety goals based on both corporate standards as well as channel-specific standards. Manage ingredient screening and toxicology, stability, compatibility and efficacy testing. Ensure conformance to specification, avoid rework and recalls by building compliance screening into new product development, validate claims through the product development process and maintain accurate raw materials data, Product Information Files and documentation (SDS, COA).

Portfolio & Merchandise Planning

Manage and optimize your product portfolio and assortments to meet performance targets and optimize new product development.

Align financial objectives with merchandise plans, run what-if scenarios and roll up actual financials for analysis in top-down and bottom-up planning. Quickly react to market changes to preserve or increase revenues and margins, control product costs by driving supply chain simplification and maintain data accuracy and completeness in product catalogs and presentations.

Product Presentations

Save time by creating visual product presentations directly in Centric PLM, pulling real-time data to ensure accuracy.

Filter products, visually organize them into sets, stay on-brand by using corporate fonts and leverage Centric PLM’s Canvas tool to build presentations that drive decision-making. Eliminate the tedious process of exporting visuals from PLM and save time by automatically updating presentations as product data changes.

Visual Assortment Board for PLM

Create superior assortments that optimize performance at retail with the ability to visually interact with live assortment plans.

The Visual Assortment Board for PLM merges thousands of live data points with image libraries to enable real-time team collaboration on what-if scenarios and stop/go assortment decisions.

Curate assortments that meet business objectives faster and with less waste, save valuable human resources, accelerate cycle time and deliver products consumers want to drive profitability across all channels.

Visual Concept Board

Supercharge product innovation by reducing manual and time-consuming tasks and empowering creative collaboration.

The Concept Board is a visually interactive, intuitive digital workspace that enables creative and product development teams to collaborate around inspirations and trends using sketches, photos, videos, 3D images and more.

Reduce or eliminate manual design board creation to free up valuable time and deliver products in a flow that enhances brand performance, consumer retention and profitability.

Visual Sourcing Board

Source more cost-effectively with the ability to compare ‘what-if’ scenarios in a visually interactive workspace.

The Sourcing Board replaces siloed tools and disconnected information, empowering sourcing teams to pull together live data and visuals from multiple platforms and files to visually compare and analyze sourcing options.

Achieve projected lead times with targeted sourcing and the ability to rapidly identify alternatives, source more sustainably and meet vendor capacity targets and production deadlines while controlling costs.

Visual Omnichannel Showroom Board

Maximize omnichannel sales opportunities with a fully digital showroom and catalog experience to reach more clients with less resources at less cost.

The Omnichannel Showroom Board enables faster, more accurate orders with a live visual interactive digital showroom. Build tailored client-centered offers using real-time product, financial and visual data, including 3D, on a single intuitive platform.

Speed time to order commitment among remote teams, eliminate unreliable paper trails and capture 100% of orders and changes digitally and in real-time. Mitigate sales risks, pivot quickly on top performers, drive targeted products across channels and forecast raw material demands accurately for earlier vendor commitment.

Execute Sustainability with Centric PLM

Raw Materials Management

Carbon Footprint

Waste Management

Supply Chain Certification

Social Responsibility

Circularity

Raw Materials Management

Brands, retailers and manufacturers need to find sustainable alternatives to materials that depend on high usage of water, energy, natural resources and harmful chemicals.

Centric PLM provides a platform to track and manage raw materials from their source, measure key sustainability criteria and identify suitable alternatives.

Carbon Footprint

One digital space for product information enables end-to-end traceability that includes carbon footprint data through integration with all leading sources of Scope 3 emissions databases.

Powerful sourcing comparison tools make it easier to understand the impact of different sourcing options and reduce the environmental cost of shipping, support local producers and make supply chains more transparent.

Waste Management

Centric PLM improves visibility and accuracy throughout the entire supply chain to lessen waste, reduce or eliminate the disposal of unwanted or unsold inventory and dramatically reduce costs associated with overstock storage.

Integration with 3D technology reduces physical sampling costs and cuts development time to increase product margins.

Supply Chain Certification

Track suppliers and their certifications, using whatever paper trail complies with your company requirements.

Manage compliance programs and vendor certification, from raw materials to labor practices to the recyclability of packaging.

Ensure transparency for consumers.

Social Responsibility

Document data at the product and factory levels to validate claims surrounding sustainability and ethics.

Set audit criteria to conform to labor, carbon footprint, resource and waste management standards.

Manage supply chains and customer communication with a truly open, quality-focused and personal approach.

Circularity

Design and develop product lines using consumer feedback, gather data on real-world product faults and repairs to inform manufacturers and improve quality, source durable materials more cost-effectively and innovate products that are designed for long service life.

Access environmental impact data to determine product end-of-life options.

For us, the carbon score is first and the margin is second. So, before we even look at the margin, we will look at whether or not we’re achieving the carbon score that we set out for ourselves. — Joe Vernachio, Chief Operating Officer at allbirds

20,000+ Brands Brought to Market with Centric Software

Fashion & Apparel

Outdoor & Sports

Multi-Category Retail

Home & Furniture

Food & Beverage

Consumer Goods

Cosmetics & Personal Care

Fashion & Apparel

Featured success stories

Outdoor & Sports

Featured success stories

Multi-Category Retail

Featured success stories

Home & Furniture

Featured success stories

Food & Beverage

Featured success stories

Consumer Goods

Featured success stories

Cosmetics & Personal Care

Featured success stories

Thirdlove Shapes Their Future with Centric PLM™

Today, ThirdLove enjoys one single source of the truth in a central data repository, their processes are more clearly defined and their tech packs are virtually error-free, ensuring operational excellence. What journey did they take with Centric PLM to solidify their digital foundation?

Read the Success Story“PLM has become one single source of truth in the creative process that didn’t exist before.”

— Marcus Chung, VP of Manufacturing and Supply Chain at ThirdLove

Rothy’s: It’s Easy Being Green with Centric PLM

Rothy’s was founded with eco-consciousness baked right into their DNA. Having efficient workflows make their mission of sustainable footwear manufacturing easier to manage.

“ From a human perspective, Centric PLM makes life much easier for our people in design, product development and manufacturing. We’re able to work directly with our factory… and eliminate the countless other manual steps that existed before Centric.”

— Heather Howard, COO at Rothy's

P.E Nation Handles Exceptional Growth with Centric PLM

Despite celebrating exceptional growth, even during the Covid-19 pandemic, Mark Rogers, Head of Operations at P.E Nation, reflects on a time when teams felt the frustration and stress of working with multiple data sources. “A small business, rapid growth, increased SKU counts – we were increasing our range across different categories and we began to see pain points.” Fast forward a matter of months and that frustration has been improved thanks to Centric PLM.

Read the Success Story“The ease of the interface, the usability, the fact that we can generate reports out of it- it’s a one-stop shop, Centric made sense to us.”

— Mark Rogers, Head of Operations at P.E Nation

Helly Hansen Boosts Product Innovation with the Power of Centric PLM

The trailbazing outdoor brand, Helly Hansen, once struggled with data management, visibility and version control across multiple software platforms. When the Helly Hansen group acquired MUSTO in 2018, integrating a new brand brought additional challenges. However, MUSTO had been a happy Centric Software® customer for many years, and, in 2019, Helly Hansen decided to also implement Centric PLM to harmonize data and processes across both brands and within Helly Hansen’s own departments.

Read the Success Story“We’re growing fast and, in order to develop innovative, high quality products efficiently, we needed a clear overview of who was doing what, where and when. Before Centric PLM, one of our biggest challenges was a lack of accountability, with each department using different tools and platforms.”

— Ferdinand Diener, Process and Quality Manager at Helly Hansen

Deuter Fuels Faster Decision Making with Centric PLM

“For the past 25 years, we have had one longstanding manufacturing partner in Vietnam who makes all of our backpacks and our developers travel there a lot. Often decisions about products are made there, on the spot. In the past, these changes were not always documented very well for our teams back home. This has now totally changed. People can discuss product alterations at the factory and enter these decisions in Centric PLM while on the road so that everyone can see them. It has very much improved our style of working.”

Read the Success StoryBetter overview of production & development schedules

Time saved searching for product information

Organized, accessible, detailed material data & BOMs

Klim Climbs Steadily Upward with Centric PLM™

“We work on such a wide variety of products that it’s just so complex to manage. Our offerings range from carbon fiber helmets, to snowmobile boots, to GoreTex outerwear pieces, to motorcycle airbags. There’s no way we could have handled it all just with Excel files and emails”.

Ryan Harris, Vice President of Product gives his observations on managing their products without PLM. KLIM recognized early on that they needed to have a single source of the truth for all product data so that critical information was accessible at all times.

25%

reduction in sample lead times

30%

increase in e-comm channel sales

Purcotton Builds a Collaborative, Efficient and Open Product Development Management Platform with Centric PLM

“The implementation of PLM saves us time and material costs, and allows us to continuously amass experience, thus realizing data aggregation throughout the value chain to form PurCotton’s brand DNA.”

Purcotton joins hands with Centric Software to build a cross-departmental PLM platform that supports multiple R&D and product ideation models, leading to more efficient operations.

1500+

system fields organized

3

strategic objectives achieved

Tape à l’Œil Meet Strategic Goals and Keep Up Team Spirit with Centric PLM

“With Centric PLM, our data is now much more reliable since each product is automatically associated with its retail price, store format and category.”

Read the Success Story3,500

products managed

6

months to implement

Riachuelo Meets Fast-Changing Consumer Demands with Centric PLM

“Because of the agility that PLM gives us, like the reduction of time to market and product development lead time, we are now able to capture new trends. For example, with changes sparked by the pandemic, our customers want more products for indoor, at-home living. We are now able to respond and quickly adapt our collections to what our customers are asking for.”

Flávia Märtino, Product Manager at Riachuelo, explains how Centric’s Product Lifecycle Management (PLM) software was crucial to delivering the exact products consumers want. PLM enabled the company to work faster and achieve cost savings, even during a time of major market disruption.

Faster time to market

Standardization of processes in different departments

More sustainability and speed in the sample cycle

Ernsting’s Family Chooses Centric Software’s Full PLM Team Support

“We feel very strongly supported by the Centric CAMS support team. Any time we have an issue, we can get an answer immediately. We have the support when we need it. It is the greatest benefit, I think!”

— Jyrina Volmer, IT Coordinator for Product Development and Software Engineering Manager at Ernsting’s family at Ernsting’s Family

Optimized processes

Freed up to focus on business and product development

Seamlessly connect PLM to other programs and platforms

Four Hands Increases Visibility, Efficiency and Accuracy with Centric PLM™

“There was no single source of truth for product information. It was scattered in multiple spreadsheets and local computers housing product attributes. You never knew which information was accurate, which was the latest version.”

Douglas Estremadoyro, VP of Business Innovation at Four Hands recalls their product development process from a few short years ago.

Today, all product information is housed in one accessible place, product development visibility and efficiencies are significantly improved, data accuracy is up and work duplication is reduced. What drove this transformation?

Visibility and reporting drastically improved

Increased process efficiencies

Improved data accuracy

Starpro Empowers R&D Management with Centric PLM

“We spent eight months evaluating and selecting an R&D system provider, using a detailed 9-step process for selection scoring. We organized and analyzed over a hundred requirements from decision-makers to actual users, and combined multiple demonstrations based on hypothetical scenarios. In the end, we chose Centric PLM. For Starpro, the process of ‘focusing more on selection than implementation’ was crucial.”

— Li Chenhong, R&D Director of Starpro

Streamlined R&D data and created a repository as a collaborative platform

Enhanced control over costs, status and risk management

Swiftly addressing customer needs through rapid iteration

Centric PLM Empowers Modern Gourmet Foods to Save Money Through Better Collaboration and Visibility

“I know we’ve saved six figures a year in project management time, simply by having a collaborative system and a single, actionable version of the truth.”

Read the Success Story$100K

saved annually on project management

60

days to implement in 2 continents

Guangzhou Restaurant Group Transforms Cantonese Cuisine with Centric PLM

“Thanks to close collaboration between the Guangzhou Restaurant R&D center and the Centric Software team, the PLM project has achieved the fastest and most user-driven implementation among all it projects ever carried out by Guangzhou Restaurant Group.”

— Huang Dayao, Business Director at Guangzhou

Improved R&D efficiency and quality

Improved integrity and utilization of R&D data

Solid data foundation for products

Centric PLM Drives Innovation to Push Market Success at InterDesign

“I want to be able to go to one place to see product dimensions, product weights, colors, colorways, to see SKUs involved . . . we did not have a tool that allowed us to do that before. It was a lot of manual work to get even fairly simple answers.”

Brandon Gray, Engineer and Subject Matter Expert at InterDesign describes the situation at their company prior to Centric PLM™.

Product information now accessible

Total product definition at the front end

Improved efficiency and communication

How Targus Powers Up Product Development with Centric PLM

“We knew that the right PLM provider would be able to share best practices from their experiences with other partners and Centric has a wealth of specialized knowledge.”

Global brand and laptop case pioneers, Targus, successfully use centric PLM to enable global product teams to work more closely with procurement teams, saving time and increasing accuracy.

5

regional offices using PLM

4

time zones collaborating

Visionnaire Drive Craftmanship and Competitiveness with Centric PLM

Today, Visionnaire has successfully implemented Centric PLM and is on track to complete its revolutionary digital project in 2020. The high-end furniture-makers have aligned information throughout the organization with a single version of the truth, giving them instant control over collection development and greater versatility in the way they configure individual products and the manufacturing process.

How did Visionnaire successfully create an integrated product data infrastructure with the support of Centric PLM?

Smooth integration with ERP and CPQ solutions

Improved transparency and communication

Ability to collaborate effectively with suppliers

KIKO Milano Drive Efficiency and Launch Products Faster with Centric PLM

“We release many new products every year. Managing all these new products and all the related data is definitely not easy, especially because the data is managed by different departments.”

Maria Viglione, Sourcing & Purchasing Manager at KIKO Milano explains the difficulties of handling complex cosmetics products without one single source of truth.

Fast forward to today, and KIKO Milano are proudly using Centric Product Lifecycle Management (PLM) to develop products from concept all the way through to store. Here is KIKO Milano’s journey.

Clear milestone management

Consistent management of accurate information

Efficient integration with ERP

Premier Anti-Aging Selects Centric PLM™ to Consolidate Product Information

Japanese cosmetics company partners with Centric Software® to improve efficiency and speed time to market of products and services

Read the Press Release

AlumierMD Selects Centric PLM™ for a Central Source of Product Information and to Save Time

AlumierMD, the medical skincare brand, has selected Centric Software®’s Product Lifecycle Management (PLM) solution. Centric Software provides the most innovative enterprise solutions to plan, design, develop, source and sell products such as apparel, footwear, sporting goods, furniture, home décor, cosmetics, food & beverage and luxury to achieve strategic and operational digital transformation goals.

Read the Press ReleaseThirdlove Shapes Their Future with Centric PLM™

Today, ThirdLove enjoys one single source of the truth in a central data repository, their processes are more clearly defined and their tech packs are virtually error-free, ensuring operational excellence. What journey did they take with Centric PLM to solidify their digital foundation?

Read the Success Story“PLM has become one single source of truth in the creative process that didn’t exist before.”

— Marcus Chung, VP of Manufacturing and Supply Chain at ThirdLove

Rothy’s: It’s Easy Being Green with Centric PLM

Rothy’s was founded with eco-consciousness baked right into their DNA. Having efficient workflows make their mission of sustainable footwear manufacturing easier to manage.

“ From a human perspective, Centric PLM makes life much easier for our people in design, product development and manufacturing. We’re able to work directly with our factory… and eliminate the countless other manual steps that existed before Centric.”

— Heather Howard, COO at Rothy's

P.E Nation Handles Exceptional Growth with Centric PLM

Despite celebrating exceptional growth, even during the Covid-19 pandemic, Mark Rogers, Head of Operations at P.E Nation, reflects on a time when teams felt the frustration and stress of working with multiple data sources. “A small business, rapid growth, increased SKU counts – we were increasing our range across different categories and we began to see pain points.” Fast forward a matter of months and that frustration has been improved thanks to Centric PLM.

Read the Success Story“The ease of the interface, the usability, the fact that we can generate reports out of it- it’s a one-stop shop, Centric made sense to us.”

— Mark Rogers, Head of Operations at P.E Nation

Helly Hansen Boosts Product Innovation with the Power of Centric PLM

The trailbazing outdoor brand, Helly Hansen, once struggled with data management, visibility and version control across multiple software platforms. When the Helly Hansen group acquired MUSTO in 2018, integrating a new brand brought additional challenges. However, MUSTO had been a happy Centric Software® customer for many years, and, in 2019, Helly Hansen decided to also implement Centric PLM to harmonize data and processes across both brands and within Helly Hansen’s own departments.

Read the Success Story“We’re growing fast and, in order to develop innovative, high quality products efficiently, we needed a clear overview of who was doing what, where and when. Before Centric PLM, one of our biggest challenges was a lack of accountability, with each department using different tools and platforms.”

— Ferdinand Diener, Process and Quality Manager at Helly Hansen

Deuter Fuels Faster Decision Making with Centric PLM

“For the past 25 years, we have had one longstanding manufacturing partner in Vietnam who makes all of our backpacks and our developers travel there a lot. Often decisions about products are made there, on the spot. In the past, these changes were not always documented very well for our teams back home. This has now totally changed. People can discuss product alterations at the factory and enter these decisions in Centric PLM while on the road so that everyone can see them. It has very much improved our style of working.”

Read the Success StoryBetter overview of production & development schedules

Time saved searching for product information

Organized, accessible, detailed material data & BOMs

Klim Climbs Steadily Upward with Centric PLM™

“We work on such a wide variety of products that it’s just so complex to manage. Our offerings range from carbon fiber helmets, to snowmobile boots, to GoreTex outerwear pieces, to motorcycle airbags. There’s no way we could have handled it all just with Excel files and emails”.

Ryan Harris, Vice President of Product gives his observations on managing their products without PLM. KLIM recognized early on that they needed to have a single source of the truth for all product data so that critical information was accessible at all times.

25%

reduction in sample lead times

30%

increase in e-comm channel sales

Purcotton Builds a Collaborative, Efficient and Open Product Development Management Platform with Centric PLM

“The implementation of PLM saves us time and material costs, and allows us to continuously amass experience, thus realizing data aggregation throughout the value chain to form PurCotton’s brand DNA.”

Purcotton joins hands with Centric Software to build a cross-departmental PLM platform that supports multiple R&D and product ideation models, leading to more efficient operations.

1500+